A kind of jacquard fabric with velvet feeling, weaving method and application thereof

A velvet and fabric technology, applied in the field of warp knitting, can solve the problems of inability to obtain partial pile fabrics, single mesh structure, single layer effect, etc., and achieve the effect of rich texture, soft hand feeling and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0056] Example of Embodiment 1

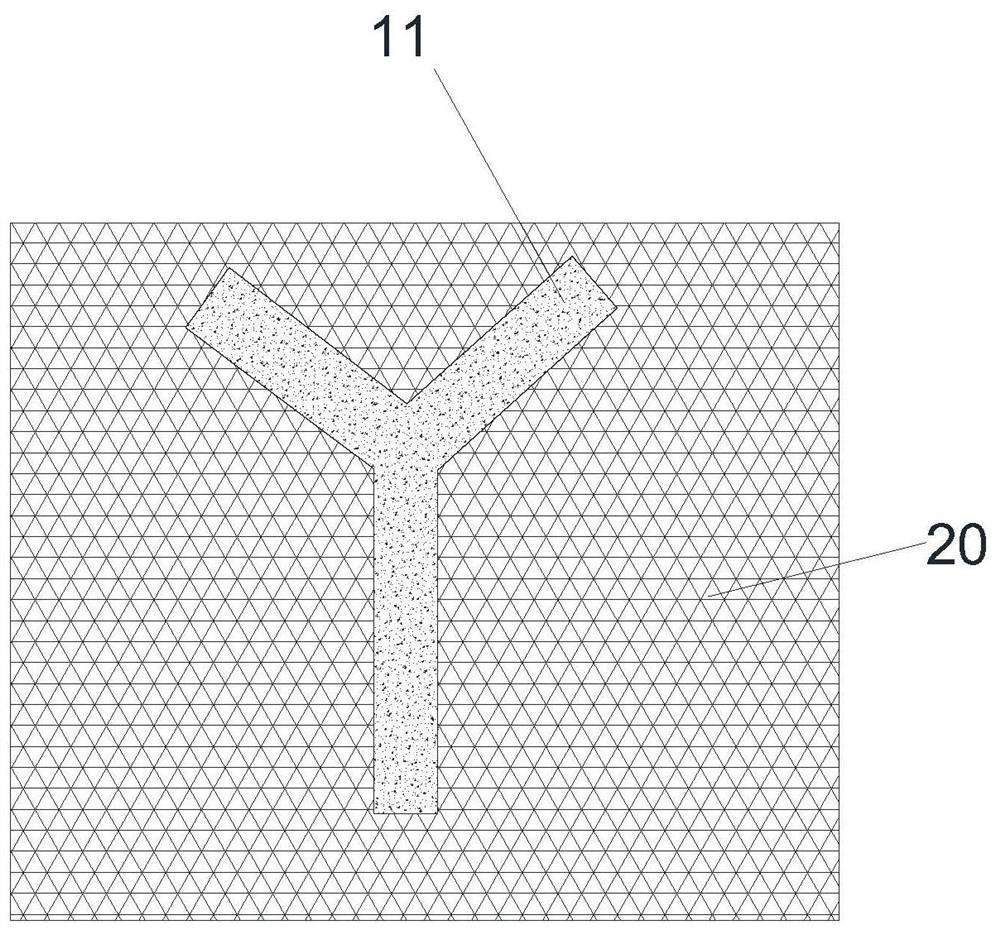

[0057] will refer to figure 1 and figure 2 The jacquard fabric with fleece feeling according to the embodiment of the present invention is described in detail.

[0058] A jacquard fabric with a fleece feeling according to an embodiment of the present invention includes a fleece feeling area 1 and a non-fleece feeling area 2, the fleece feeling area 1 and the non-fleece feeling area 2 are integrally woven, and the jacquard fabric is made of a Three groups of combs are knitted by double needle bed warp knitting jacquard machine. The first group of combs includes two separate jacquard combs JB3 and JB4, and the second group of combs includes ground combs. Bar GB5, the third group of bars includes ground bar GB6 and ground bar GB7, and the first group of bars, the second group of bars and the third group of bars are arranged adjacently in sequence;

[0059] The non-velvet area 2 includes a first surface layer 20, a first middle layer 21 and a f...

Embodiment approach 2

[0077] Example of Embodiment 2

[0078] According to an embodiment of the present invention, there is provided a jacquard mesh fabric of a sandwich structure with a fleece feeling.

[0079] Specifically, the jacquard fabric with a fleece feeling according to an embodiment of the present invention includes a fleece feeling area 1 and a non-fleece feeling area 2 , the fleece feeling area 1 and the non-fuzzy feeling area 2 are integrally woven, and the jacquard The fabric is woven by a double-needle-bed warp knitting jacquard machine with three groups of bars, wherein the first group of bars includes four separate Jacquard bars JB3, Jacquard bars JB4, Jacquard bars JB5, Jacquard bars JB6, the second group of bars includes ground bars GB7, the third group of bars includes ground bars GB8, and the first, second and third groups of bars arranged next to each other;

[0080] The non-velvet area 2 includes a first surface layer 20, a first intermediate layer 21 and a first bottom la...

Embodiment approach 3

[0099] Example of Embodiment 3

[0100] According to an embodiment of the present invention, there is provided a sandwich jacquard fabric in which the second surface layer has a partial single-hole silk exposed fleece effect and has a Q property.

[0101] More specifically, the jacquard fabric with pile feeling according to the embodiment of the present invention includes a pile feeling area 1 and a non-fleece feeling area 2, the pile feeling area 1 and the non-fleece feeling area 2 are integrally woven, and the jacquard feeling area is The card fabric is woven by a double needle bed warp knitting jacquard machine with three groups of bars, wherein the first group of bars includes two separate jacquard bars JB3 and JB4, and the second group of bars Including ground combs GB5, ground combs GB6 The third group of combs includes ground combs GB7 and ground combs GB8, and the first group of combs, the second group of combs and the third group of combs arranged next to each other;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com