Mechanical flocculation basin

A flocculation tank and mechanical technology, applied in the field of water treatment, can solve the problems of dead water affecting the flocculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

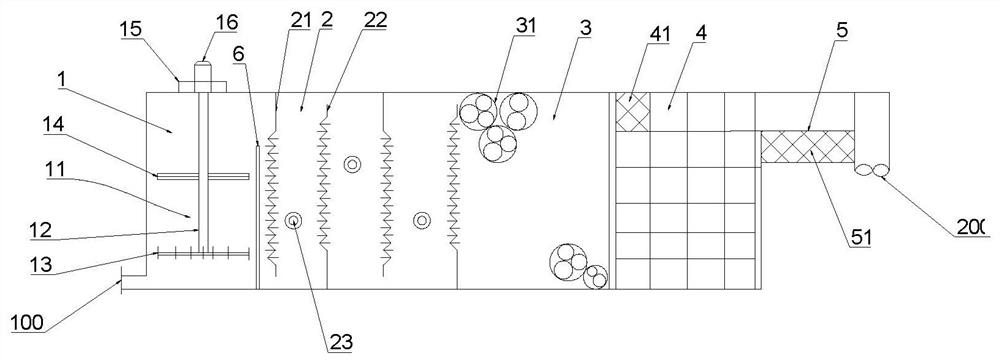

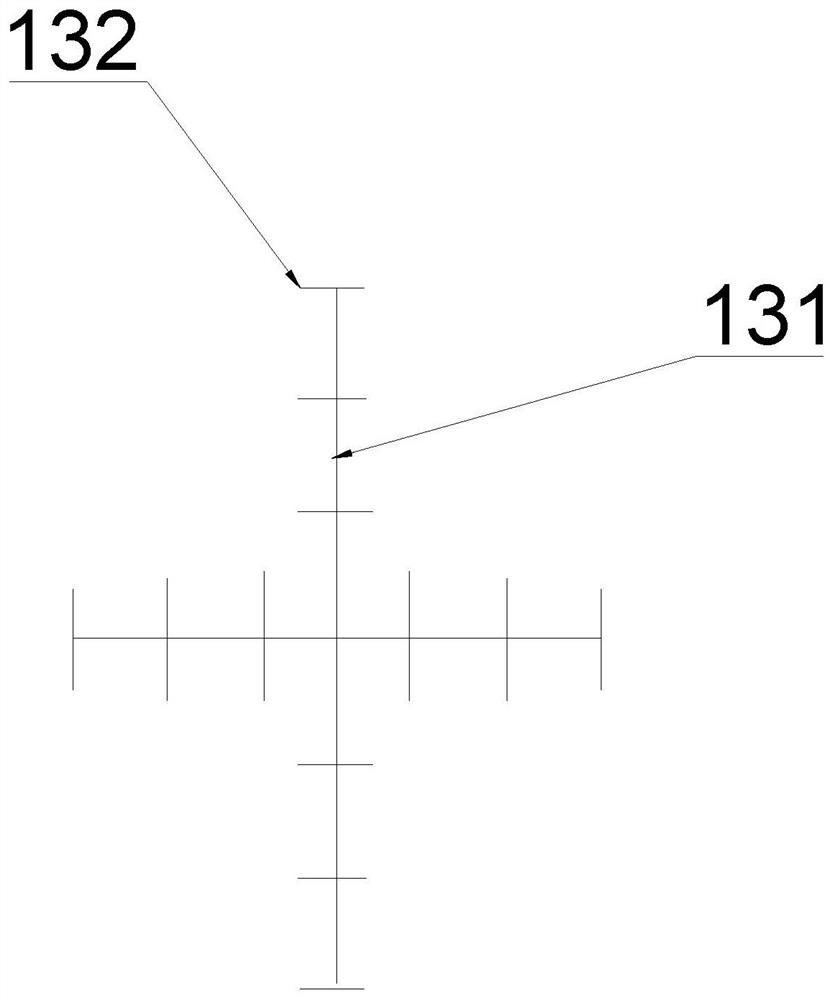

[0016] Such as figure 1 , figure 2 The shown mechanical flocculation tank includes a tank body, a water inlet 100 and a discharge port 200. The tank body includes a first-level tank 1, a second-level tank 2, a third-level tank 3, a fourth-level tank 4 and The outlet pool 5, the water inlet 100 is connected with the bottom of the first-stage pool 1, the outlet pool 5 side is provided with a drain port 200, and the vertical double-layer agitator 11 arranged vertically is installed in the first-stage pool 1. Double-deck stirrer 11 comprises stirring shaft 12, such as image 3 The stirring paddle-13 shown and as Figure 4 Shown stirring paddle two 14, stirring shaft 12 is connected with motor 16 by speed reducer 15, combines image 3 Stirring paddle one 13 comprises cross rod 131 and the stirring rod 132 that is installed on the cross rod 131, and stirring rod 132 can adopt as Figure 6 In the shown shape, the stirring paddle 2 14 includes a six-fold stirring paddle 141 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com