Efficient and energy-saving down filling machine

A high-efficiency, energy-saving, down-filling machine technology, applied in the field of down-filling machines, can solve the problems of lack of internal fluff breaking device, easy clumping of fluff, unfavorable quality of load-bearing products uniformity, etc., to improve economic efficiency and better quality , better quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

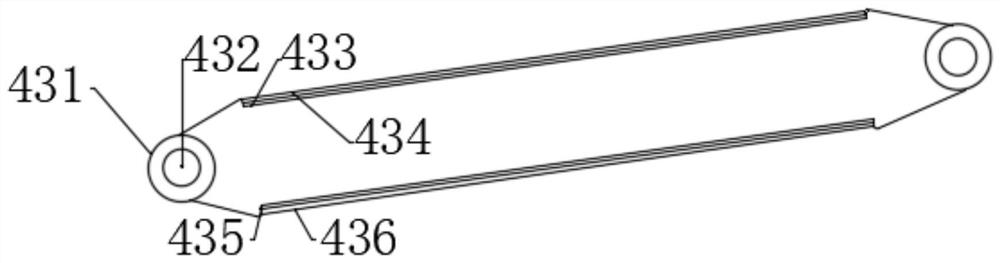

[0030] see Figure 1~4 , in an embodiment of the present invention, a high-efficiency and energy-saving down filling machine includes a top cover 1, and the inside of the top cover 1 is used for installing a device for initially processing down down. Top cover 1 is provided with top fillet 2 around the peripheral part, and the top of the middle part of top cover 1 is provided with feeding hole 3, and the middle part of top cover 1 is internally rotated and installed with breaking device 4, and the effect of breaking up device 4 is Fluff the fluff directly inside the unit. The side parts of the breaking device 4 are engaged with a longitudinal rod device 5, and the effect of the longitudinal rod device 5 is to realize the linkage of the bottom auxiliary device. A mounting plate 6 is fixedly installed on the top of the longitudinal rod device 5 , and the mounting plate 6 is a fixing device for the longitudinal rod device 5 . The bottom of the middle part of the top cover 1 is ...

Embodiment 2

[0035] see Figure 5-6 The difference between this embodiment of the present invention and Embodiment 1 is that the conveying device 12 includes a roller shaft 121 fixedly installed at the bottom of the bottom cover 8 at the side, and a belt 122 is sleeved on the surface of the roller shaft 121. The belt 122 The inner ring of the belt 122 is fixedly equipped with an internal flange 123, and the outer surface of the belt 122 is fixedly equipped with an external flange 124, and the effect of the flange is exactly to transmit fluff.

[0036] The rear part of the middle part of the turntable 41 is fixedly equipped with an insert shaft 24 , the surface of the insert shaft 24 is fixedly equipped with bevel teeth 25 , and the side parts of the bevel teeth 25 are meshed with engaging bevel teeth 26 .

[0037] The meshing bevel teeth 26 are plugged and installed on the surface of the longitudinal bar device 5 .

[0038] The working principle of the present invention is:

[0039] When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com