Sealing mode for bottle body of one-way valve of automatic liquid discharging machine

A one-way valve, liquid machine technology, used in sealing, closing, packaging and other directions, can solve problems such as liquid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

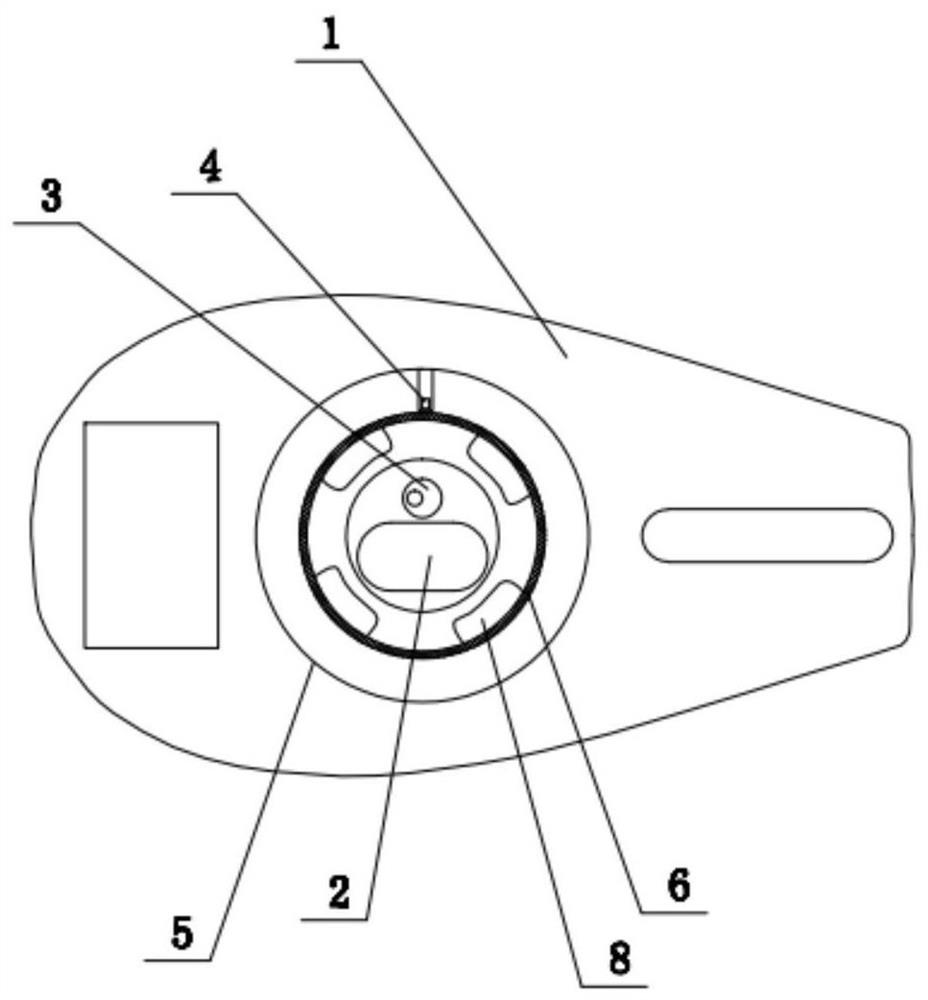

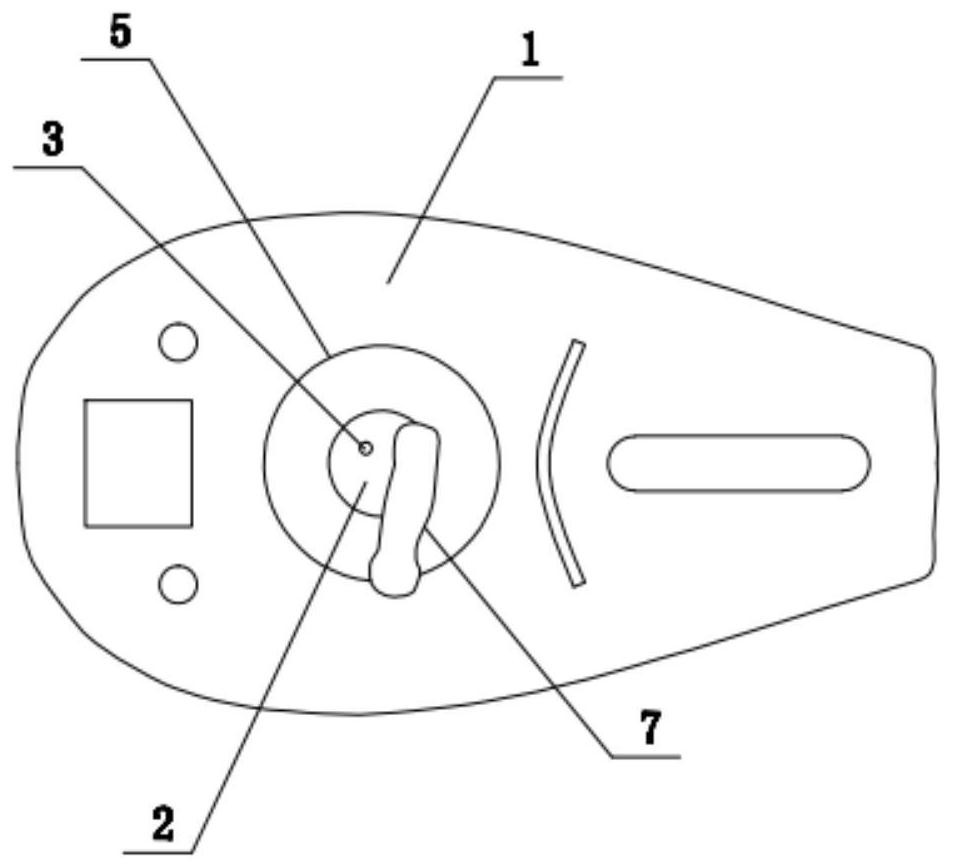

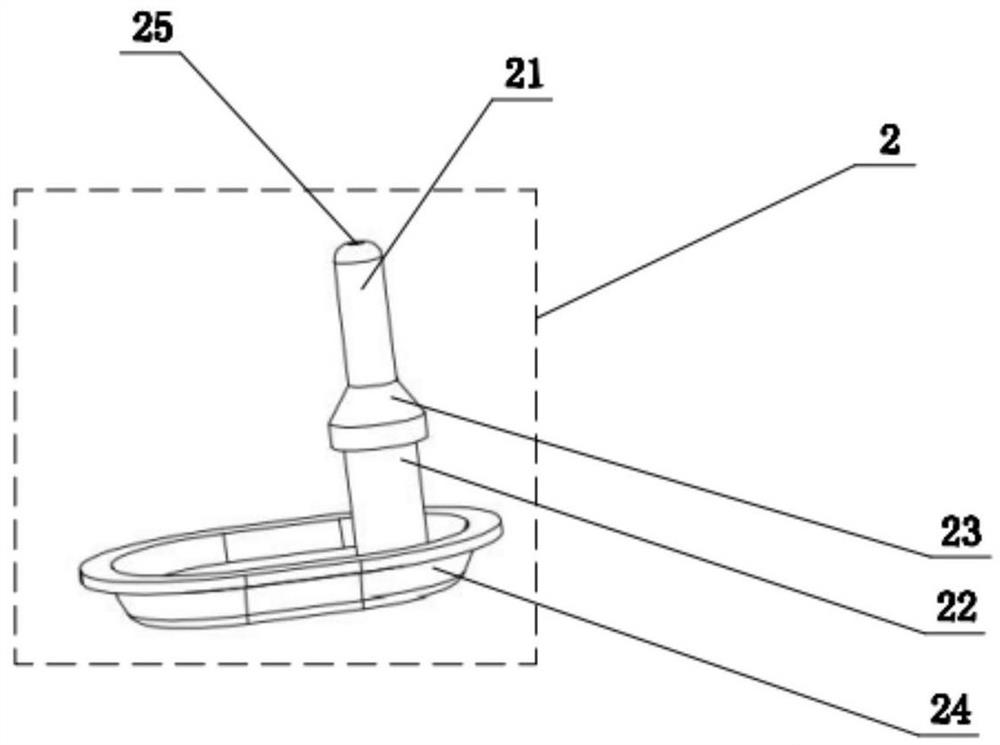

[0019] see Figure 1-Figure 3 As shown, the technical solution adopted in this specific embodiment is: it includes the one-way valve bottle cap of the automatic liquid discharge machine, and the one-way valve bottle cap of the automatic liquid discharge machine includes a lower casing 1, a one-way valve body 2, a suction Liquid hole 3, air inlet 4, connection surface 5, sealing ring 6, air intake pipe 7 and card 8, the connection surface 5 is arranged in the central area of the bottom of the lower housing 1, the connection surface 5 is circular, and the The liquid suction hole 3 is set near the center point of the connecting surface 5, the air inlet 4 is set on the edge of the connecting surface 5, the one-way valve body 2 is installed on the connecting surface 5, and the sealing The ring 6 is arranged between the air inlet 4 and the liquid suction hole 3, the card 8 is arranged annularly inside the sealing ring 6, the air inlet pipe 7 is arranged on the back of the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com