Bag replenishing method

A technology of bag refilling and bag refilling machine, which is applied in the field of bag refilling, can solve the problems that affect the efficiency of bag refilling and cannot be effectively guaranteed, and achieve the effect of improving bag refilling efficiency and smooth bag refilling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

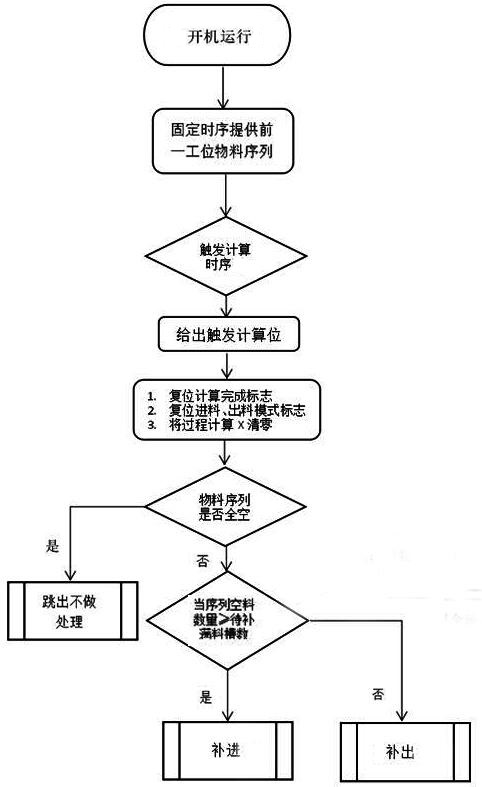

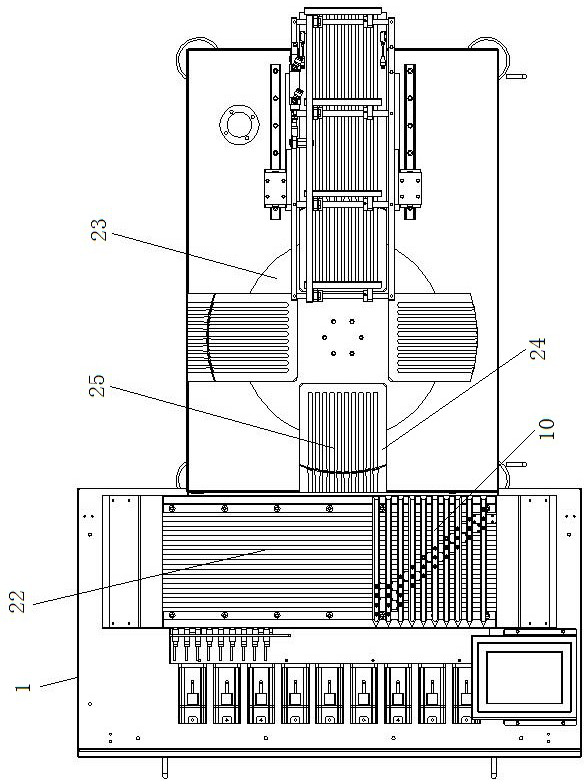

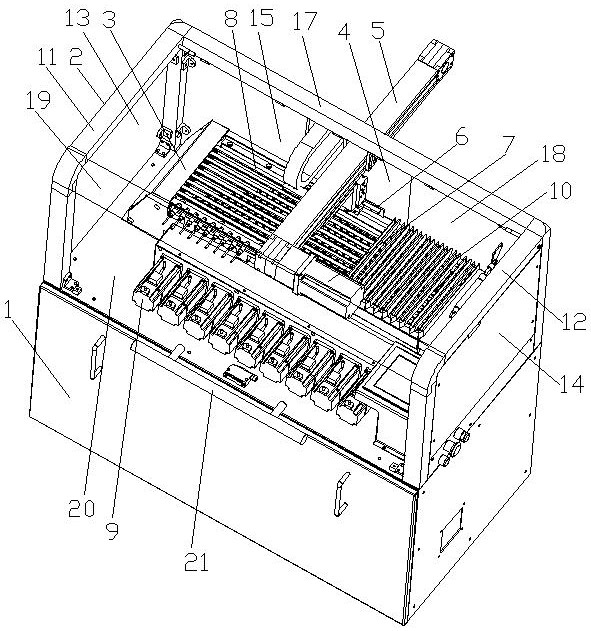

[0043] see Figure 1-Figure 5 , a kind of filling bag method, comprises the following steps:

[0044] a. When the production line is turned on for the first time, the troughs 10 to be replenished on the multi-column bag replenishing machine are all concentrated in the initial area, and the multi-column bags are detected first;

[0045] b. If the material sequence is all empty, it will jump out and do nothing;

[0046] c. In the first cycle, the material sequence is set to be full and the filling tank 10 of the waiting station 22 of the multi-column bag filling machine is completely empty, and the filling action is performed;

[0047] d. In the next cycle, if it is found that there is a lack of material in the bag replenishment trough 25, then the replenishment action will be performed; if the bag replenishment trough 25 is full, then jump out and do nothing; If it is greater than the empty bag quantity in the bag replenishing chute 25, it will still be replenished. After sev...

Embodiment 2

[0050] see Figure 1-Figure 5 , a kind of filling bag method, comprises the following steps:

[0051] a. When the production line is turned on for the first time, the troughs 10 to be replenished on the multi-column bag replenishing machine are all concentrated in the initial area, and the multi-column bags are detected first;

[0052] b. If the material sequence is all empty, it will jump out and do nothing;

[0053] c. In the first cycle, the material sequence is set to be full and the filling tank 10 of the waiting station 22 of the multi-column bag filling machine is completely empty, and the filling action is performed;

[0054] d. In the next cycle, if it is found that there is a lack of material in the bag replenishment trough 25, then the replenishment action will be performed; if the bag replenishment trough 25 is full, then jump out and do nothing; If it is greater than the empty bag quantity in the bag replenishing chute 25, it will still be replenished. After sev...

Embodiment 3

[0060] see Figure 1-Figure 5 , a kind of filling bag method, comprises the following steps:

[0061] a. When the production line is turned on for the first time, the troughs 10 to be replenished on the multi-column bag replenishing machine are all concentrated in the initial area, and the multi-column bags are detected first;

[0062] b. If the material sequence is all empty, it will jump out and do nothing;

[0063] c. In the first cycle, the material sequence is set to be full and the filling tank 10 of the waiting station 22 of the multi-column bag filling machine is completely empty, and the filling action is performed;

[0064] d. In the next cycle, if it is found that there is a lack of material in the bag replenishment trough 25, then the replenishment action will be performed; if the bag replenishment trough 25 is full, then jump out and do nothing; If it is greater than the empty bag quantity in the bag replenishing chute 25, it will still be replenished. After sev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com