Production equipment of circuit breaker shell

A technology for production equipment and circuit breakers, which is applied in the field of production equipment for circuit breaker shells, can solve problems such as increasing the workload of production personnel, and achieve the effects of ingenious structure, quick operation, and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

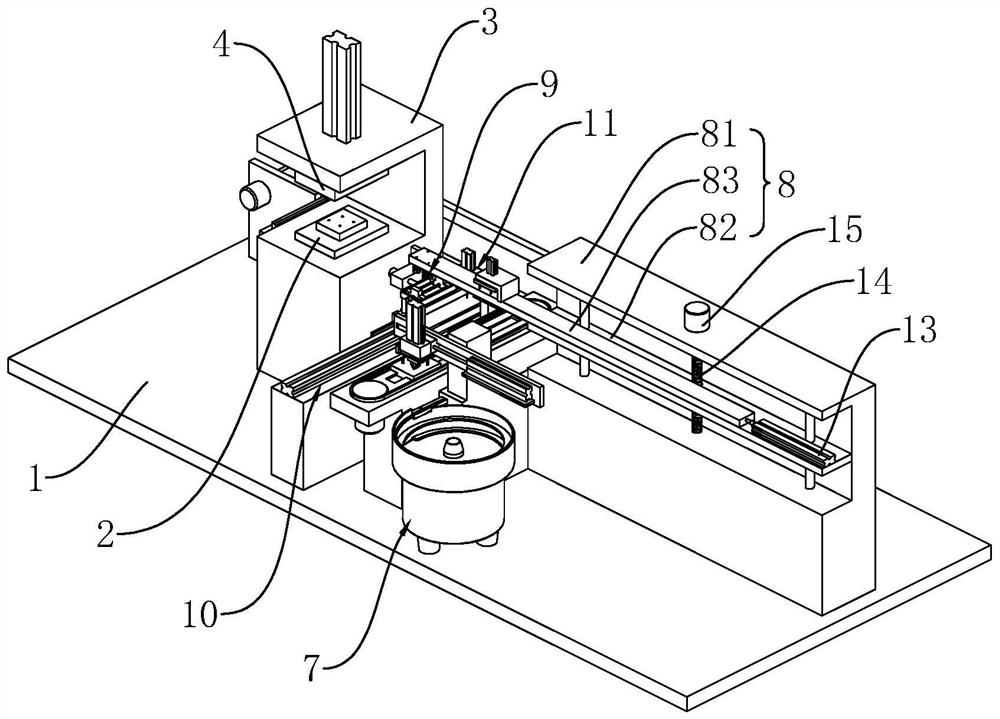

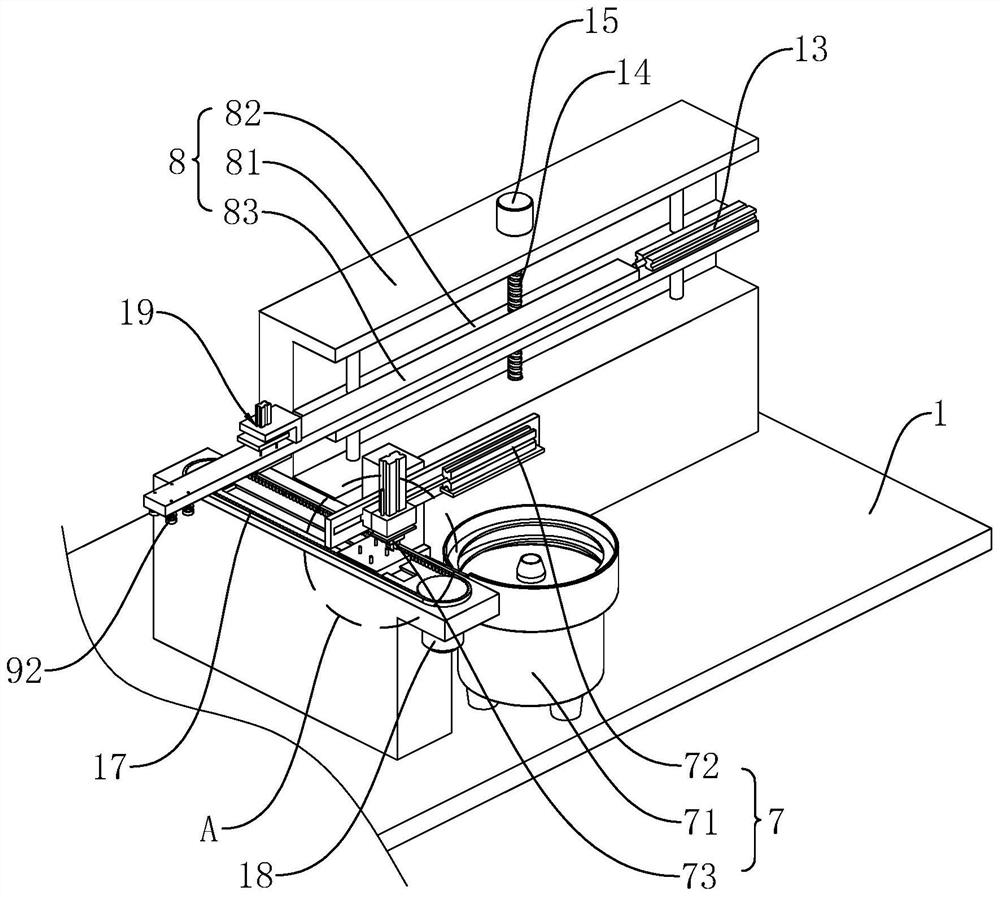

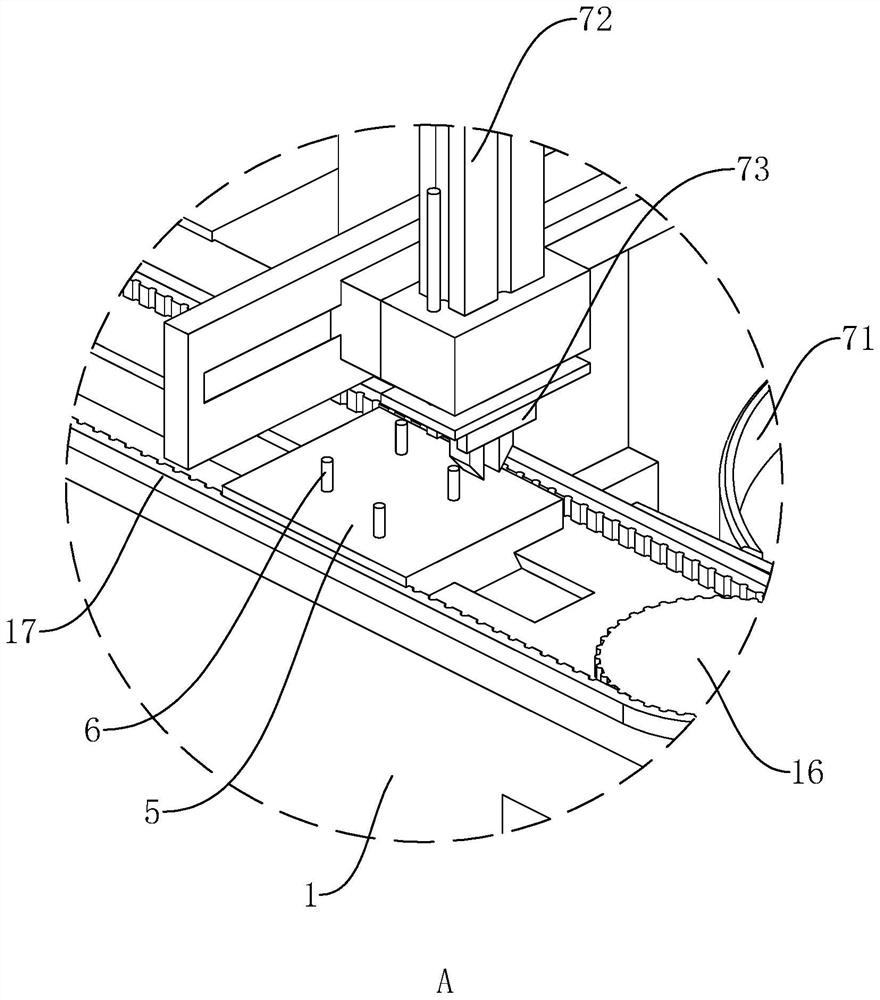

[0042] The following is attached Figure 1-8 The application is described in further detail.

[0043] The embodiment of the present application discloses a production equipment for a circuit breaker housing. refer to figure 1 , The production equipment of the circuit breaker housing includes a workbench 1, and a lower mold 2 is arranged on the upper end surface of the workbench 1. Simultaneously, a punching machine 3 is fixedly connected to the upper end surface of the workbench 1 , and an upper die 4 matched with the lower die 2 is fixedly connected to the piston end of the punching machine 3 . At the same time, channels for the heating medium to flow are reserved on the upper mold 4 and the lower mold 2 . When the upper mold 4 and the lower mold 2 are closed, and the upper mold 4 and the lower mold 2 are heated, the material can be thermoset and molded into a casing.

[0044] refer to figure 2 with image 3 , the upper end surface of the workbench 1 is horizontally pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com