Vertical soil thermal desorption device with internal and external heating and self-weight blanking functions

A technology of internal and external heating and soil heating, applied in the field of soil thermal desorption, can solve the problems of low heating rate and uneven heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

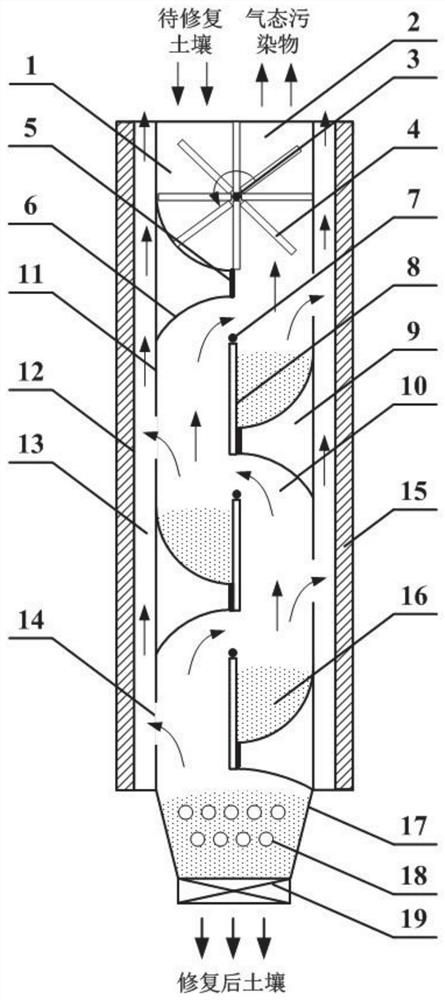

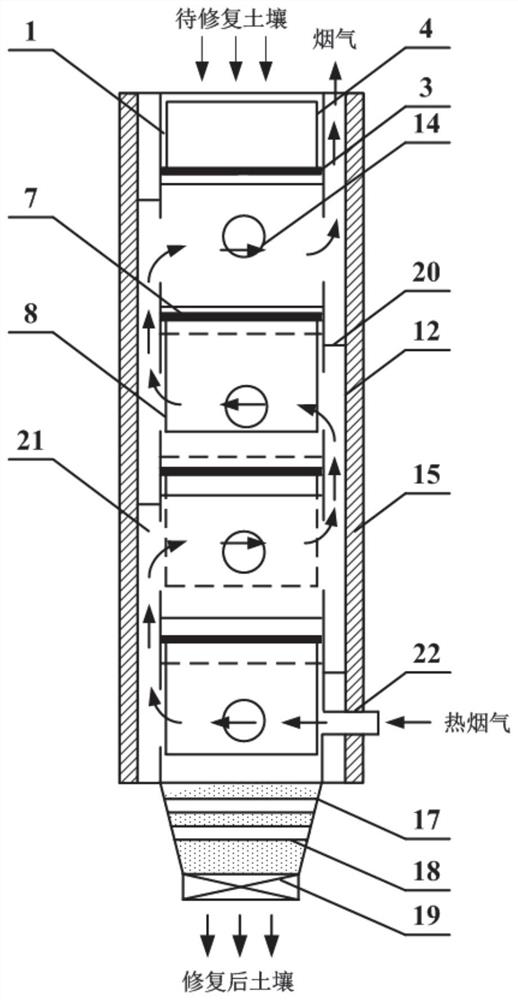

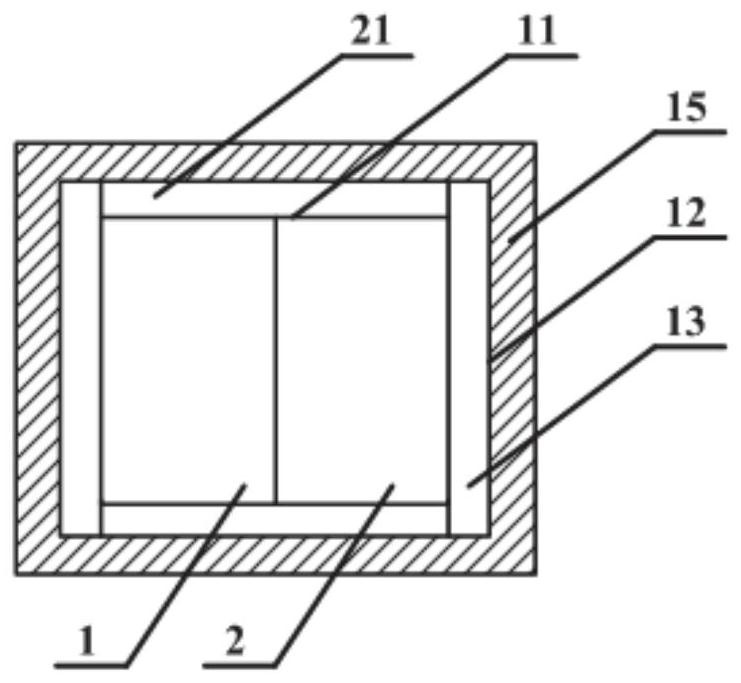

[0029] Such as figure 1 As shown, the vertical soil heat desorption device for internal and external heating and self-weight cutting of the present embodiment includes an inner channel 11, an outer channel 12 sleeved outside the inner channel 11, and a gap between the inner channel 11 and the outer channel 12 A mutually independent air channel 13 and flue 21 are formed at each place; multiple thermal desorption units are arranged in the inner channel 11, and the structure of each thermal desorption unit includes a movable baffle 8 and a heating chamber 9, and the two ends of the heating chamber 9 are respectively There are flue gas inlets and outlets connected to the flue 21; each heating chamber 9 has at least one arc plate 6, and the arc plate 6 and the movable baffle 8 constitute a soil heating area, and the movable baffle 8 is under the action o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com