Turbulent gas generating unit and honeycomb type turbulent gas generating device

A technology of gas generating unit and gas generating device, applied in the field of turbulent gas generating unit and generating device, turbulent gas generating device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

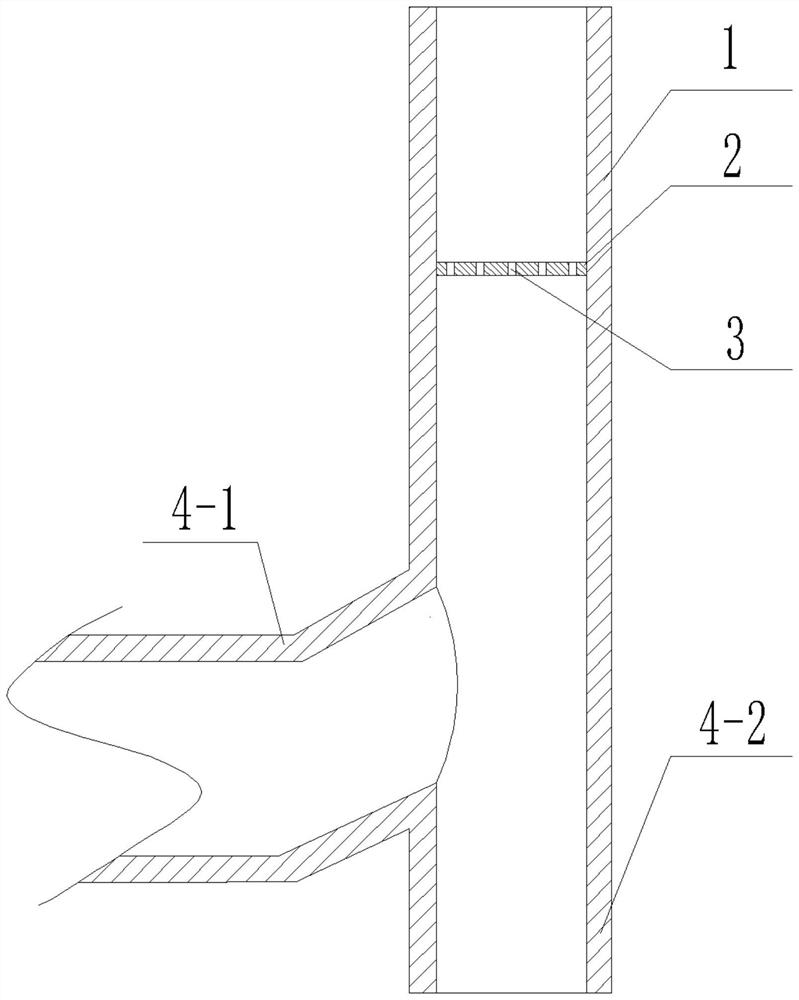

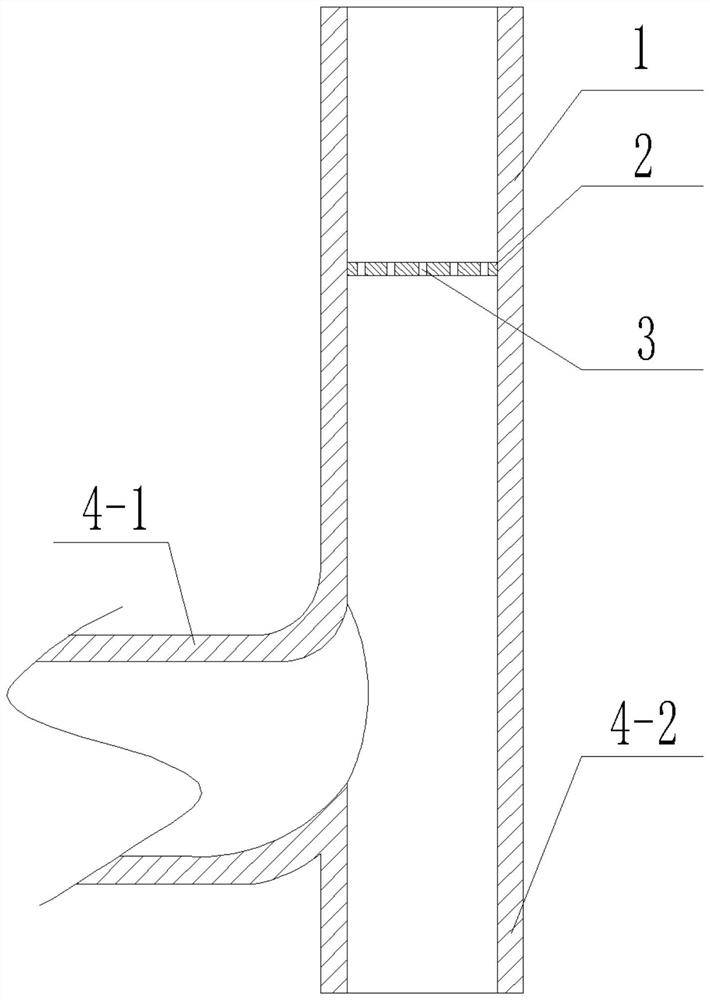

[0025] see figure 1 , a turbulent gas generating unit, the key is: the structure of the turbulent gas generating unit includes a vertically placed cylinder 1 with a top liquid storage port and a bottom liquid drop port 4-2, an air supply branch 4-1, and the partition plate 2 arranged in the cylinder 1 and above the air supply branch 4-1, the air supply branch 4-1 is connected with the cylinder 1 to form a three-way structure 4, and a partition 2 is distributed with a A set of through holes 3 for amplifying the wind speed.

[0026] see figure 2 , in order to make all the wind sent by the fan blow upwards, the connection between the air supply branch 4-1 and the cylinder 1 is an inclined upward connection structure or a curved upward connection structure.

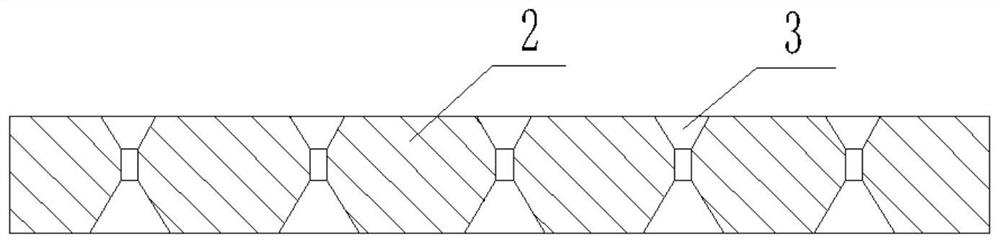

[0027] see image 3 and Figure 4 , the through hole 3 is an hourglass-shaped structure with a large upper and lower diameter and a small middle diameter.

[0028] see Figure 5 and Image 6 , the through-holes 3 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com