Parking lock and method for assembly thereof

A parking lock and parking technology, which is applied in the direction of transmission control, components with teeth, belts/chains/gears, etc., can solve problems such as increasing installation workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

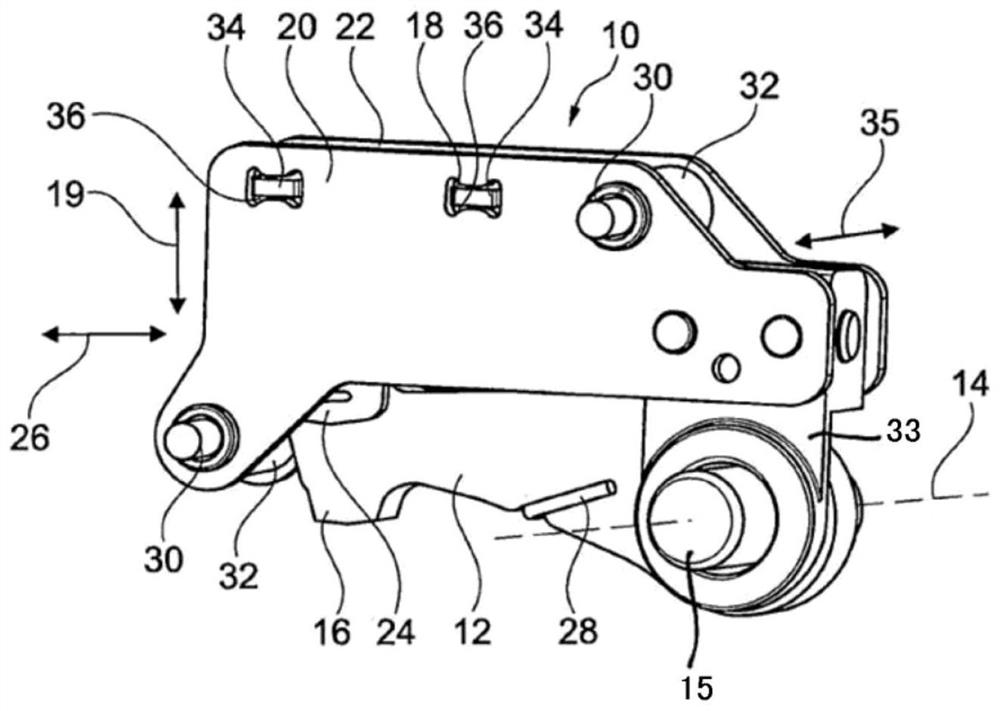

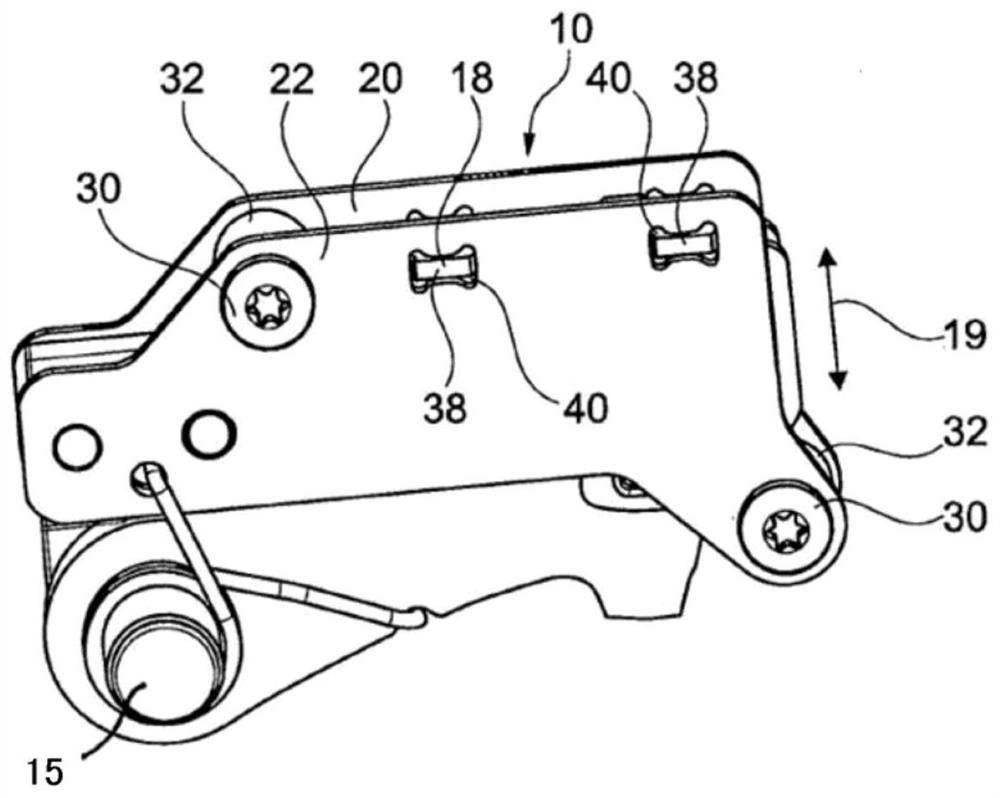

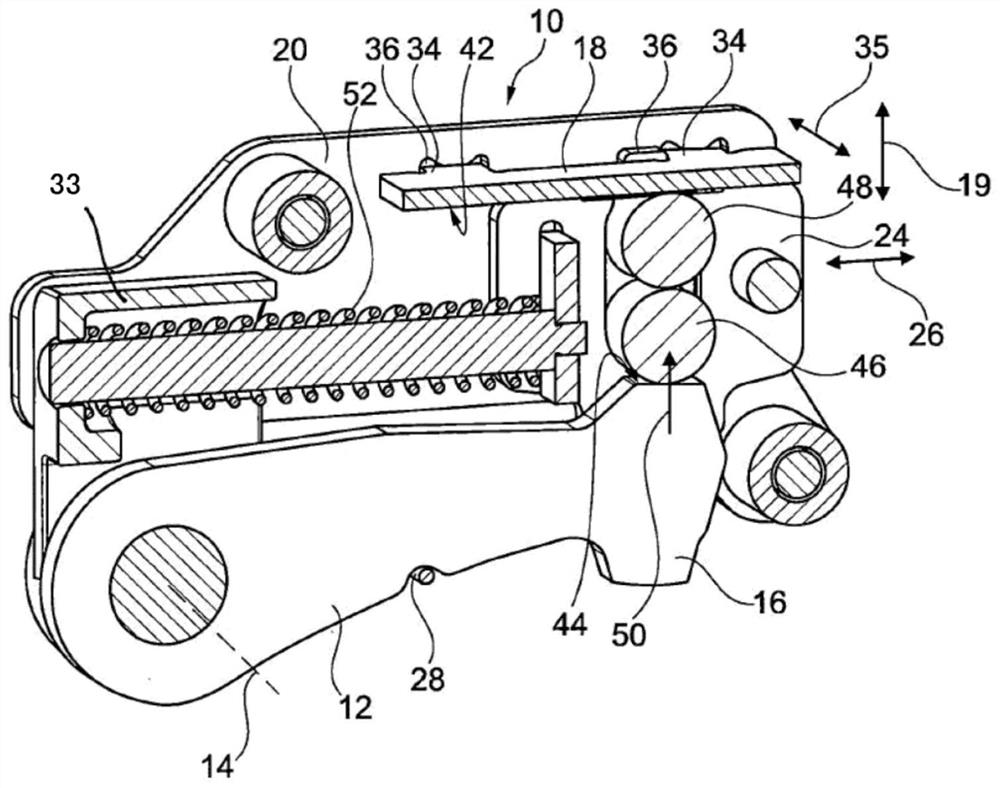

[0031] figure 1 A parking lock device 10 is shown with a locking pawl 12 which can be rotated about an axis of rotation 14 . As the locking pawl 12 rotates, the ratchet 16 integrally formed therewith moves substantially in a radial direction 19 relative to the main drive shaft (not shown). The parking lock device 10 is intended to be installed in the vehicle transmission of a motor vehicle and immobilizes a parking lock wheel (not shown) connected in a rotationally fixed manner to the main drive shaft. For this purpose, the parking lock wheel has a locking tooth system arranged on its outer circumference, into which the ratchet 16 can be locked in a form-fitting manner.

[0032] The locking pawl 12 is held by a return spring 28 which prevents the locking pawl from inadvertently locking on the parking lock wheel due to gravity in an unloaded state.

[0033]The parking lock device 10 also has a first housing wall 20 and a second housing wall 22 which are arranged as plate part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com