Stably-placed can bottom code spraying detection machine for food processing

A food processing and detection machine technology, applied in the direction of measuring devices, cleaning methods and tools, cleaning methods using tools, etc., can solve the problems of reducing the work efficiency of operators, difficult adjustment of devices, poor stability, etc., to achieve enhanced operability and The effects of stability, enhanced protection, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

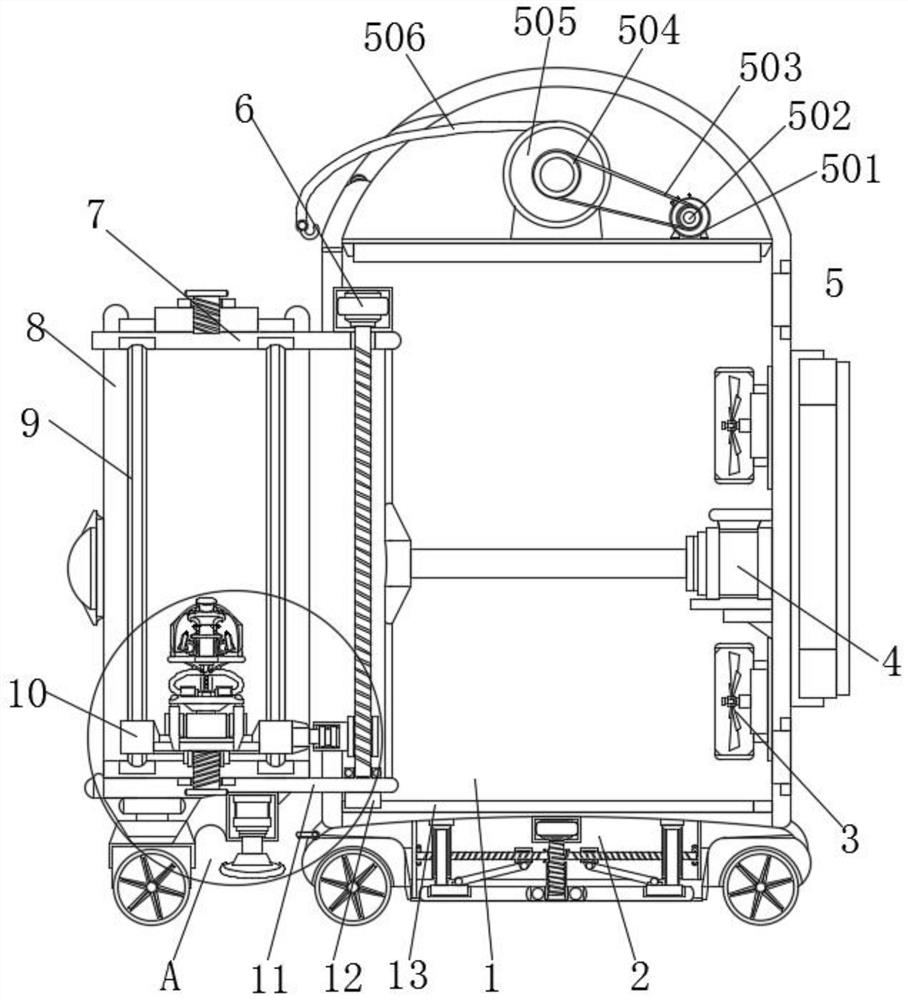

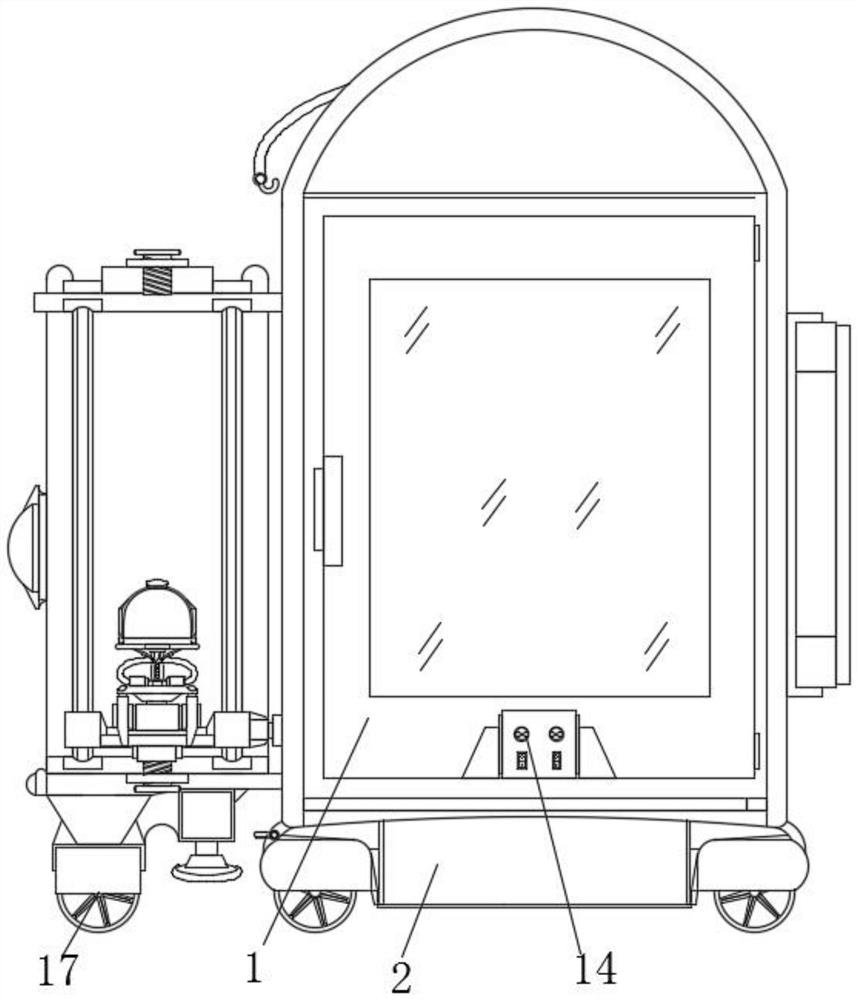

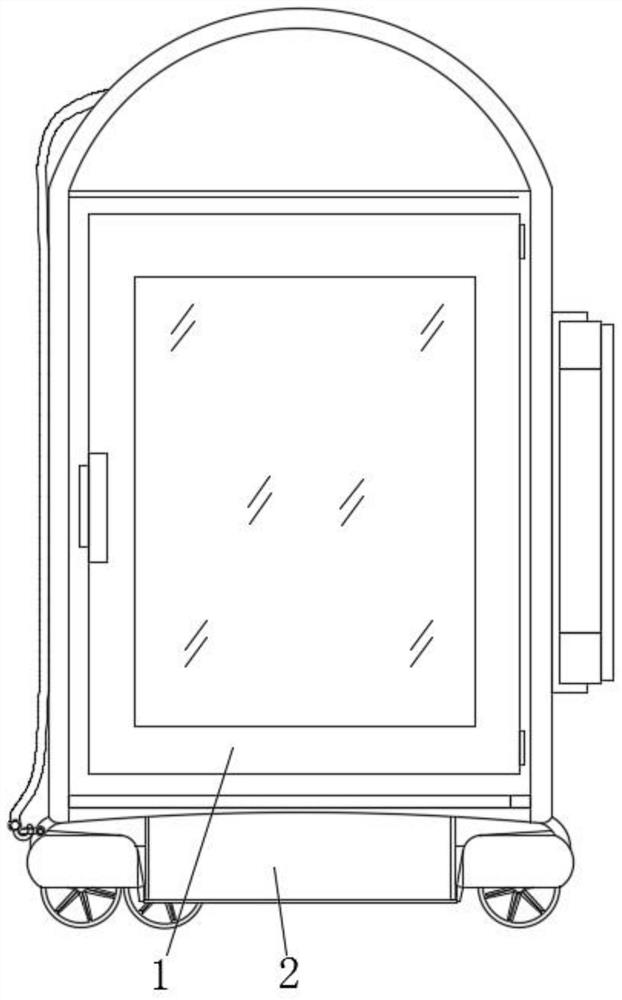

[0046] Example 1, such as Figure 1-3 As shown, when the device is not in use, the electric push rod A4 can be used to retract the installation frame 11 into the body 1 as a whole, and the pulley A502 is driven to rotate by the start of the servo motor A501, and the belt 503 is driven by the pulley A502 to cooperate with the pulley B504 to promote The belt pulley B504 drives the winding roller 505 to rotate, so that the covering cloth 506 is flipped down. At this time, the operator can manually pull the covering cloth 506 to close the opening of the body 1 as a whole, and inject cooling air into the body 1 by starting the fan 3, and the detection The residual heat of the probe 158 is rapidly cooled after work, which provides the protection function of the coding detection mechanism and increases the protection of the device.

Embodiment 2

[0047] Example 2, such as Figure 4-8 As shown, when the device needs to change the detection orientation of the detection probe 158 to the tank top or the bottom of the tank, the start of the servo motor B6 can be used to drive the threaded column 155 to rotate, forcing the threaded column 155 to drive the internal threaded block 156 to rise. The rise of the internal thread sleeve block 156 drives the chute 154 to force the pulley 153 to guide and slide, and utilizes the pulley 153 to drive the slider A10 to slide and lift along the semi-arc chute 9. The arc-shaped sliding fit makes the slider A10 finally drive the mounting base 15 and the detection probe 158 to turn over 90° as a whole. At this time, the position is positioned by the cooperation of the fixing bolt 152 and the fixing nut 151, and the detection can be carried out according to the detection requirements of the operator. The spray code detection work on the top and bottom of food tanks enhances the convenience a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com