Automatic bar microscopic examination equipment

A bar and microscopic inspection technology, applied in the field of laser bar appearance inspection, can solve the problems of high labor intensity, low inspection efficiency, and difficulty in mass production, and achieve the effect of improving inspection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

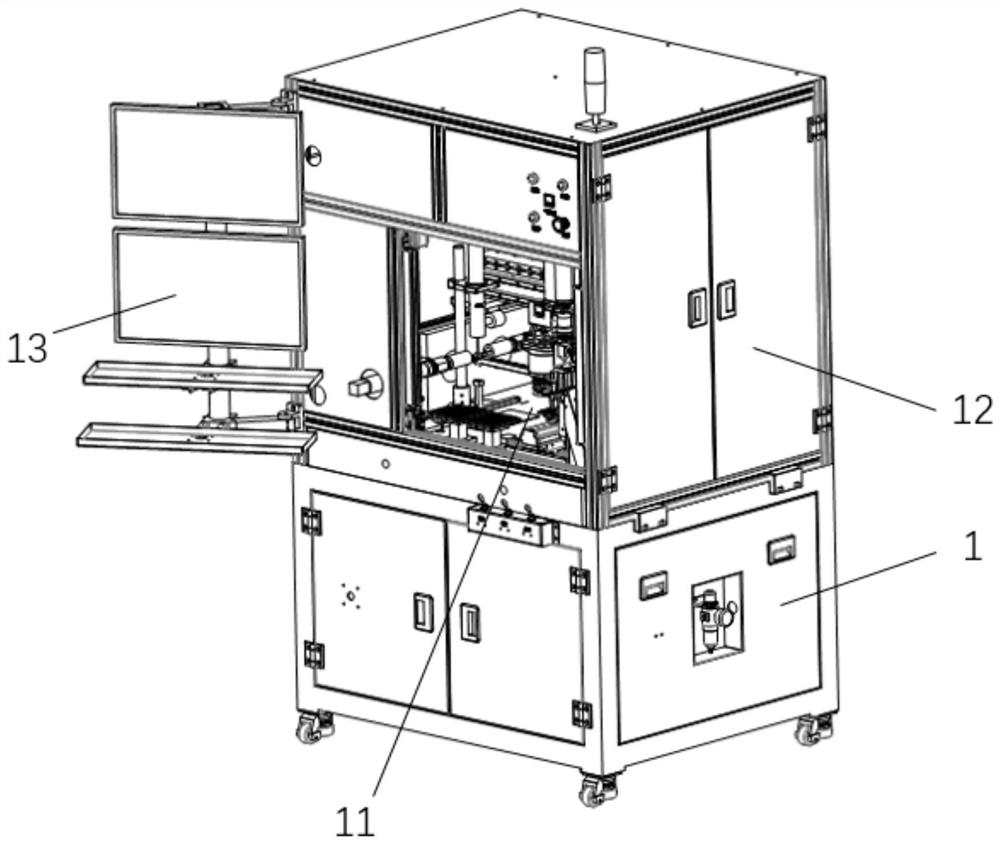

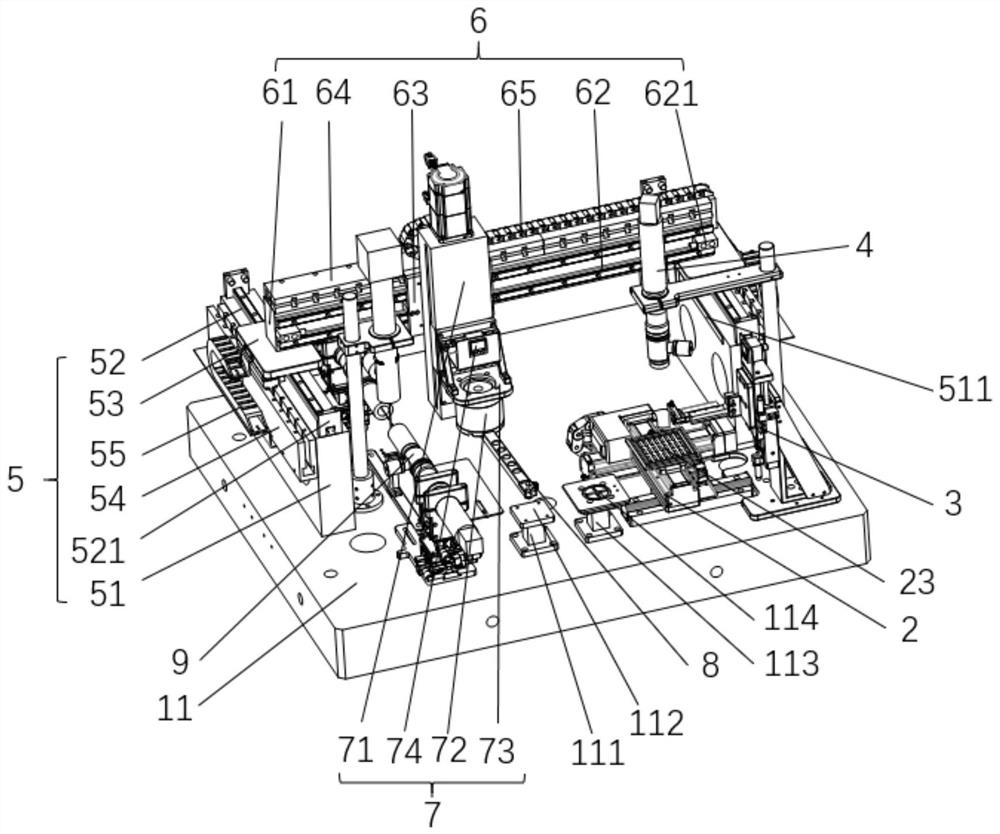

[0050] refer to figure 1 and figure 2 , the present application provides a bar automatic microscope inspection equipment, which includes a lower frame 1 and an upper frame 12, and a work platform 11 is installed between the lower frame 1 and the upper frame 12. The work platform 11 is a marble platform. The work platform 11 is provided with a loading tray 23, a first loading and unloading assembly 3, a second loading and unloading assembly 8 and a camera detection assembly 9. The work platform 11 is also provided with a The Tray tray transfer assembly 2 for moving the Tray tray 23 and the second loading and unloading assembly moving device for driving the second loading and unloading assembly 8 to move, wherein:

[0051] Feeding Tray dish 23, is used for depositing several bars to be tested;

[0052] The first loading and unloading assembly 3 is used to take the bar to be tested in the feeding tray 23, and put the detected bar back into the feeding tray 23;

[0053] The se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com