Sealed cabin sampling system

A sampling system and airtight cabin technology, applied in the field of volatile organic compound testing equipment, can solve the problems of air pressure reduction, affecting test accuracy, etc., achieve uniform distribution, improve test accuracy, and ensure accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

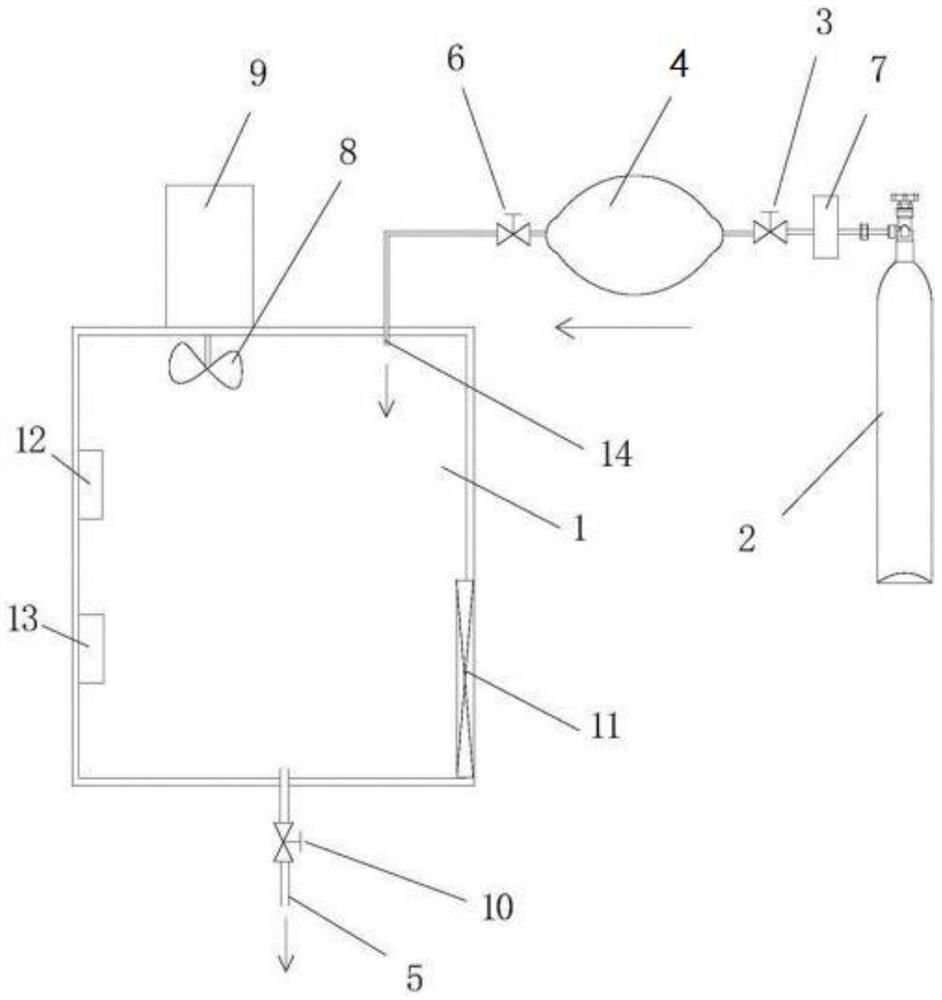

[0034] Please refer to figure 1 , Embodiment 1 of the present invention provides a closed cabin sampling system, including a constant temperature and humidity clean cabin body 1 for providing a standard test environment, the cabin body 1 is provided with an exhaust sampling port 5, and the cabin body 1 is connected with a During the gas sampling process, the gas volume inside the cabin 1 is compensated to prevent the polluted gas outside the cabin from entering the cabin 1 due to the pressure difference. The gas compensation device is located outside the cabin 1.

[0035] Wherein, cabin body 1 is provided with cabin door 11, and cabin body 1 is airtight state, and cabin body 1 is provided with stirring blower 8, and stirring blower 8 is connected with the motor 9 that is installed on the cabin body 1, and stirring blower 8 can Stir the gas inside the cabin body 1 evenly. The outer wall or inside of the cabin body 1 can be equipped with equipment such as a filter device, a hea...

Embodiment 2

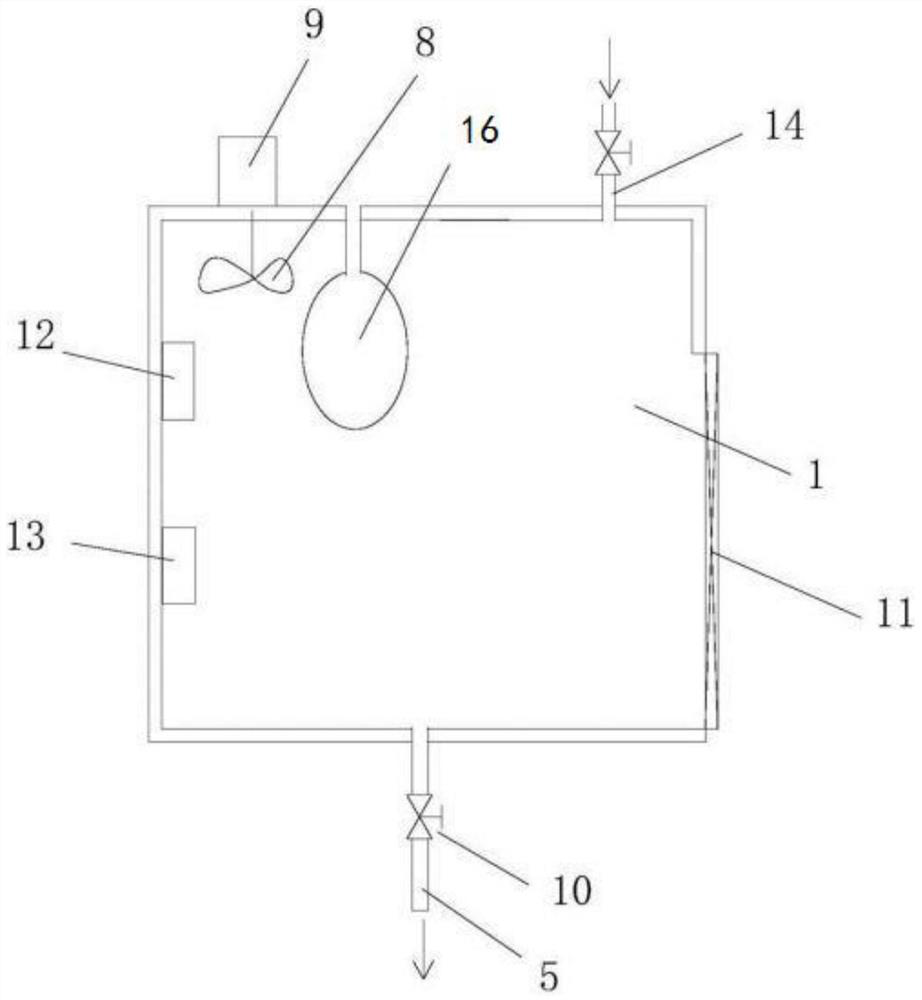

[0050] Please refer to figure 2 , the embodiment of the present invention provides a closed cabin sampling system, including a constant temperature and humidity clean cabin body 1 for providing a standard test environment, the cabin body is provided with an exhaust sampling port 5, and the cabin body is connected with a It is a gas compensation device that compensates the gas volume inside the cabin to prevent the polluted gas outside the cabin from entering the cabin due to the pressure difference.

[0051] Wherein, the cabin body is provided with hatch door 11, and the cabin body is airtight state, is provided with agitating fan 8 in the cabin body, and agitating fan 8 is connected with the motor 9 transmission that is installed on the cabin body, and agitating fan 8 can be to the inside of cabin body. The gas is stirred evenly. The outer wall or inside of the cabin body can be provided with equipment such as filtering device, heating temperature control device 12 and / or r...

Embodiment 3

[0068] Please refer to image 3 Embodiment 3 of the present invention provides another airtight cabin sampling system, including a constant temperature and humidity clean cabin body 1 for providing a standard test environment, the cabin body 1 is provided with an exhaust sampling port 5, and the cabin body 1 is connected with a During the gas sampling process, the gas volume compensation is performed inside the cabin body 1 so as to prevent the polluted gas outside the cabin from entering the cabin body 1 due to the pressure difference. The airtight cabin sampling system of the third embodiment of the present invention is the same as that of the first embodiment above Most of the structures of the airtight cabin sampling system are the same, and the similarities will not be repeated. The difference lies in the design of the gas compensation device, which is sealed and fixed on the bulkhead of the cabin body with a large opening.

[0069] like image 3 As shown, the gas compen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com