High-precision short-radius rotary steering drilling tool

A rotary steerable drilling, high-precision technology, applied in directional drilling, earthwork drilling, borehole/well components, etc., can solve the problems of small borehole curvature, poor economic benefits, long deflection section, etc., to eliminate a lot of space , save energy, shorten the length of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

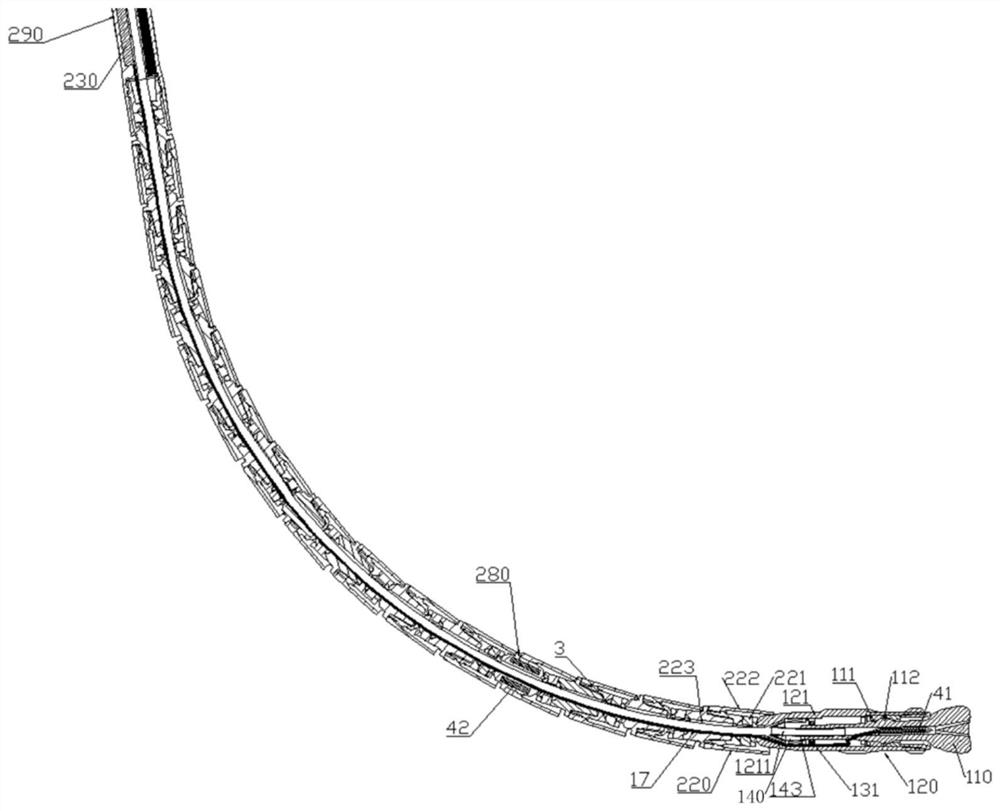

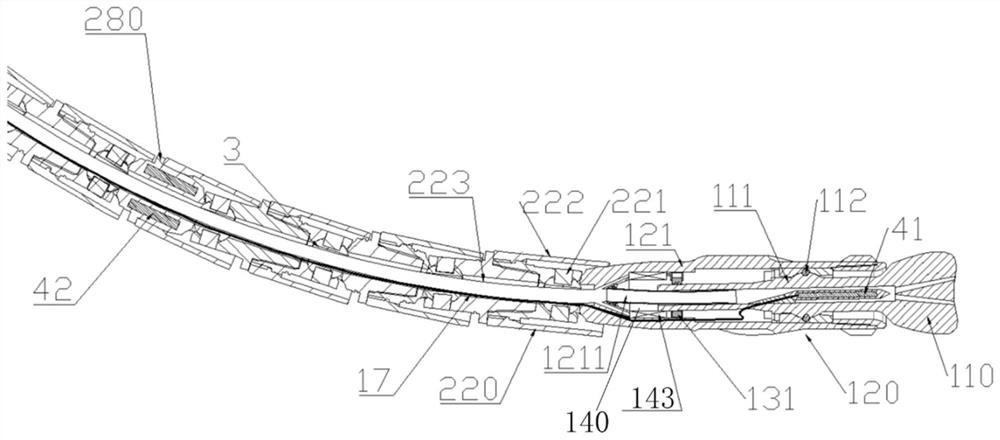

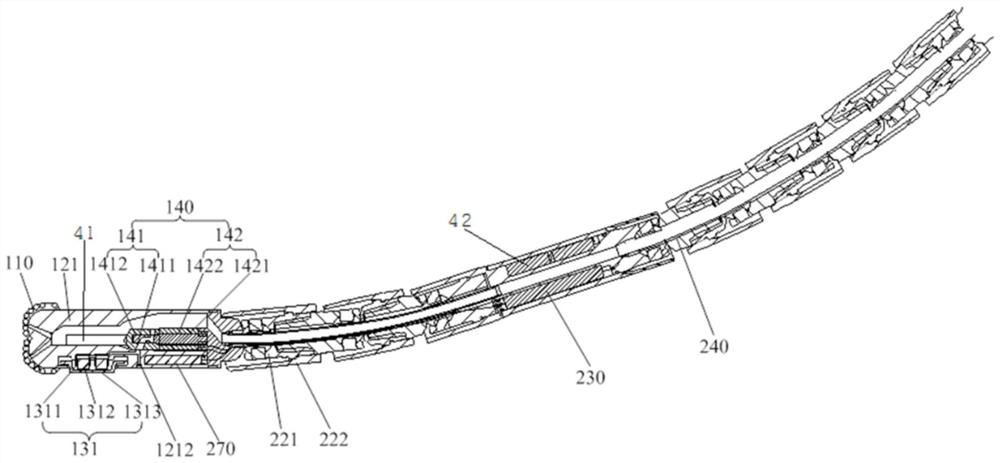

[0057] Example 1: See attached Figure 1-8 , in the figure: number 3 is a through structure, number 281 is a circuit pressure body, and number 282 is a pressure sleeve. The present invention provides a technical solution: a high-precision short-radius rotary steering drilling tool, which includes a steering drilling The nipple 100, the weight-on-bit torque deflection transmission mechanism 220, the driving nipple 290, and the driving drill string 200, wherein the pilot drilling nipple 100 is driven and connected to the driving nipple 290 through the driving drill string 200, and the driving nipple 290 is fixed inside There is an electric drive actuator drive module 230, the guide drilling sub 100 is composed of a drill bit 110 and a guide sub 120, the guide sub 120 includes a bearing body 121, the end of the bearing body 121 is fixed with the drill bit 110, and the bearing body 121 is provided with The drill bit attitude measurement module 41, the electric drive actuator 140, ...

Embodiment 2

[0072] Example 2: See attached image 3 , the present invention provides a second control deflection driving technical solution: a guide drilling sub 100, which includes a drill bit 110 and a guide sub 120, and the guide sub 120 includes a bearing body 121, and the bearing body 121 is provided with a deflection The guide mechanism 130 and the drill bit attitude measurement module 41, the drill bit attitude measurement module at least includes an accelerometer arranged axially and capable of measuring the axial acceleration component, and a magnetometer arranged axially capable of measuring the axial magnetic flux, the The drill bit 110 is connected to the lower end of the carrying body 121, and the deflection guide mechanism can drive the drill bit to deflect in a preset direction;

[0073] The driving drill string 200 includes a plurality of load-bearing sub-joints connected sequentially from top to bottom, the lowermost load-bearing sub-joint is in contact with the load-bear...

Embodiment 3

[0086] Example 3: See attached Figure 4 The present invention provides a third control deflection driving technical solution: the electric drive actuator 140 includes a plurality of solenoid valves 143 corresponding to each driving hydraulic cylinder 131 one by one, and each solenoid valve 143 is electrically connected to the drive module 230 of the electric drive actuator. connection, the solenoid valve 143 has a first passage and a second passage, the first passage communicates with the driving hydraulic cylinder 131, the second passage communicates with the through flow channel 1211, and the solenoid valve 143 can connect the through flow channel 1211 with the drive hydraulic cylinder 131 Perform periodic communication; specifically, the electrically driven actuator drive circuit 230 opens the path of the two-position two-way valve corresponding to the driving hydraulic cylinder 131 in the sector opposite to the guiding direction, so that the high-pressure fluid in the thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com