Hoisting device for prefabricated building residence construction

A prefabricated and architectural technology, applied in cranes, transportation and packaging, and load hanging components, etc., can solve problems such as broken ropes, heavy force on ropes, and heavy weight, so as to improve construction efficiency and reduce swing range , the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

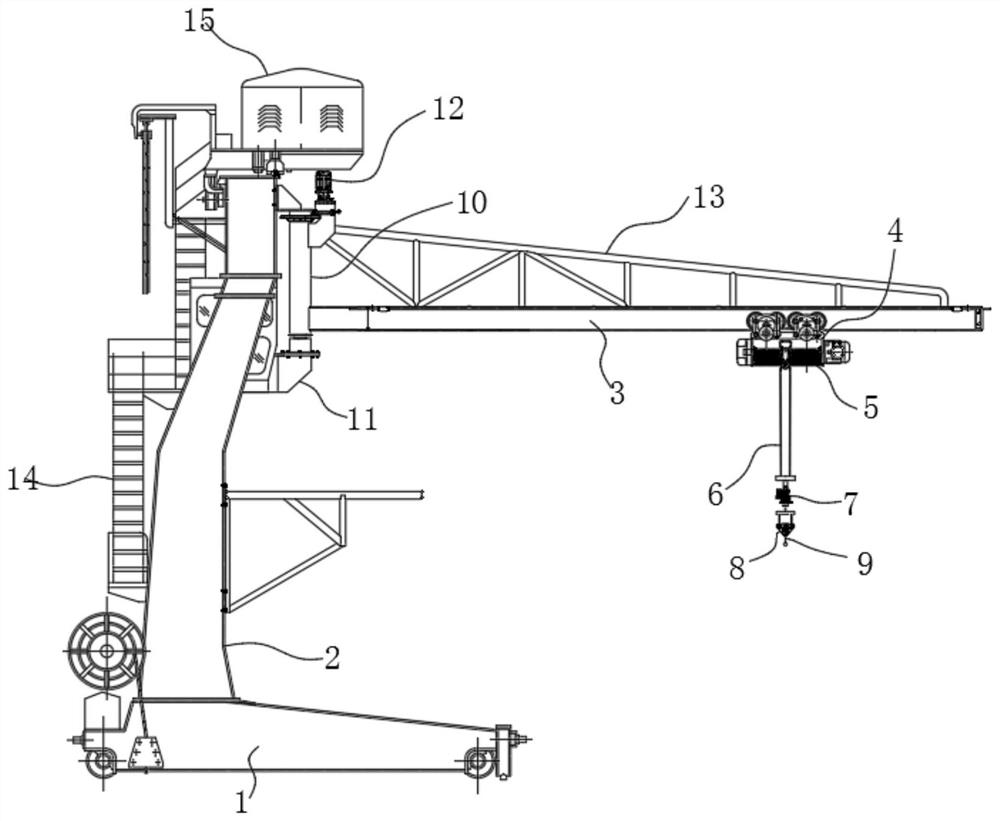

[0025] see Figure 1~4 , in an embodiment of the present invention, a hoisting device for prefabricated building construction, including a base 1, a column 2, a trolley frame 3, a walking device 4 and a hoist 5, wherein the column 2 is fixed on the base 1 , the end of the column 2 away from the base 1 is provided with a tackle frame 3 that can rotate around the column 2, and the trolley frame 3 is provided with the winch 5 using a walking device 4, and the retraction of the winch 5 The end is the rope body 6,

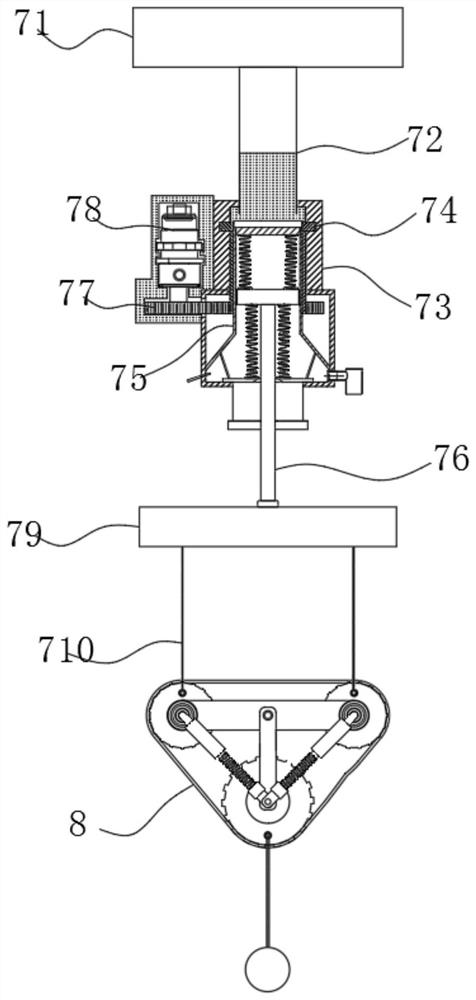

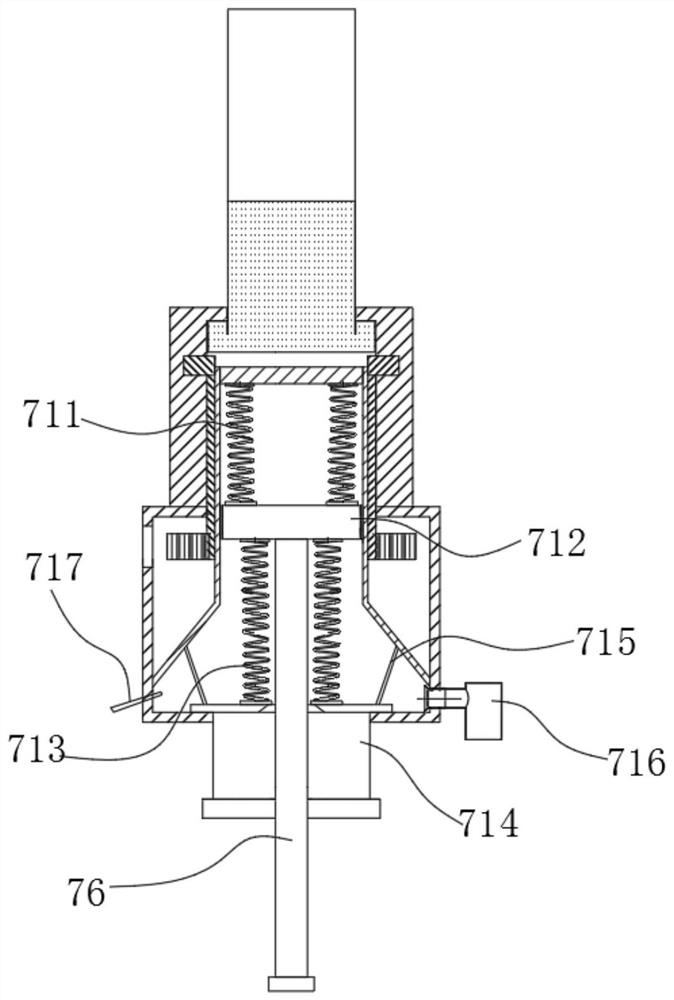

[0026] The end of the rope body 6 away from the hoist 5 is provided with a buffer control assembly 7, the buffer control assembly 7 at least includes a buffer assembly capable of buffering vertical force, and during buffering, the buffer assembly can provide three kinds of co-action The buffering force, so as to realize the buffering when lifting the assembled building materials, the buffer end of the buffer assembly is connected with the anti-swing assembly 8, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com