High-performance spring air hole sleeve

A high-performance, air hole cover technology, applied in the field of tire vulcanization, can solve the problems of inconvenient disassembly and replacement, falling off, affecting the use effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

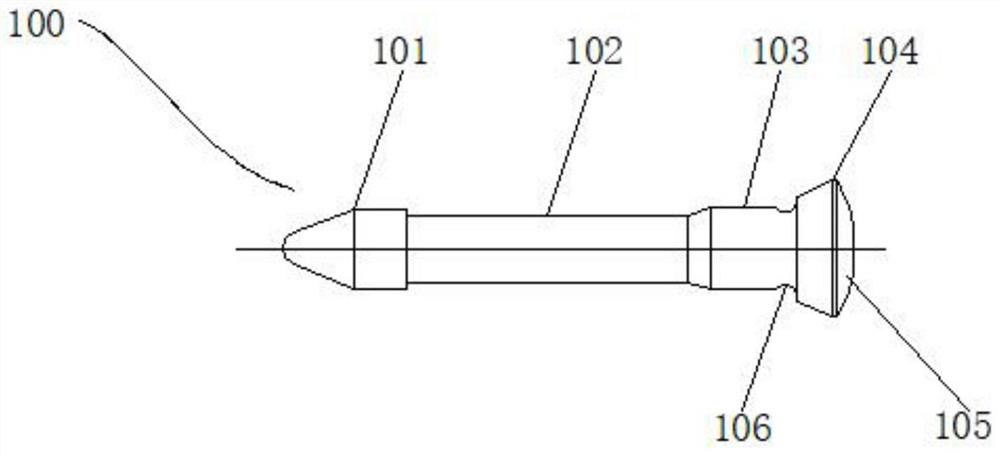

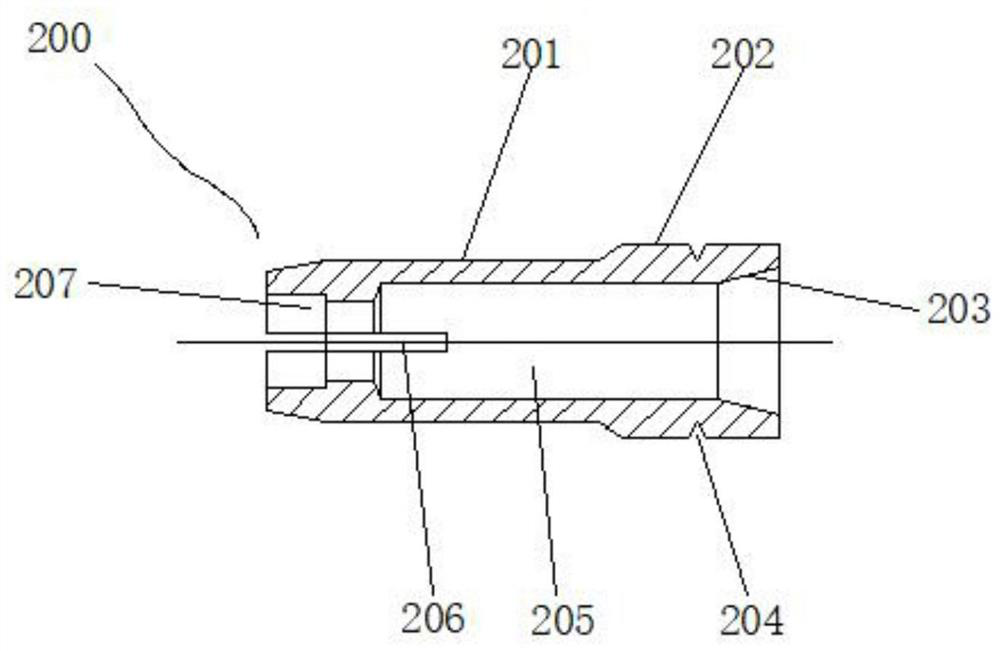

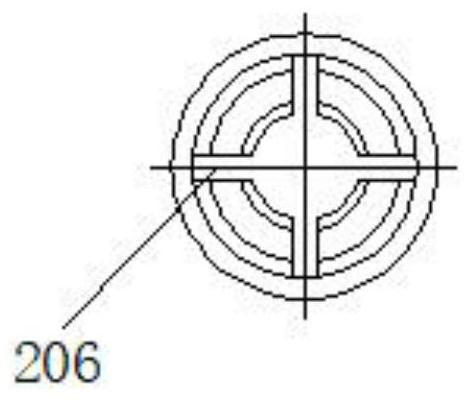

[0029] like figure 1 , Figure 2a , Figure 2b and Figure 2c As shown, a high-performance spring air hole sleeve provided in this embodiment includes a valve housing 200, a mandrel 100 and a spring. In the valve casing 200, the valve casing 200 has a cavity 205 that penetrates up and down. One end of the cavity 205 is a tapered hole 203 that is sealingly matched with the frustum portion 104 of the mandrel 100, and the other end is a spigot of the mandrel 100. The part 101 is limited to the gear part 207 outside the valve casing 200, the spring is sleeved on the mandrel 100, and its two ends are respectively against the end faces of the frustum part 104 and the gear part 207; the valve housing 200 is in the gear A notch groove B206 is provided at the top of the position part 207 to form a multi-lobed structure at this position. The notch groove B206 extends axially along the valve casing 200 to its valve body; The second outer cylinder 202 corresponding to the taper hole 2...

Embodiment 2

[0034] like figure 1 , Figure 3a , Figure 3b and Figure 3c As shown, the high-performance spring air hole sleeve provided in this embodiment differs from the preferred embodiment 1 in that in this embodiment, the gear part 207 of the valve housing 200 is a cylindrical hole, and the diameter of the cylindrical hole is smaller than the inner diameter of the bore 205 . In order to meet the design function of the structure itself, the diameter of the cylindrical hole needs to be larger than the diameter of the shaft body 102 of the mandrel 100 and smaller than the maximum outer diameter of the mouth portion 101 of the mandrel 100 .

Embodiment 3

[0036] like figure 1 , Figure 4a , Figure 4b and Figure 4cAs shown, the high-performance spring air hole sleeve provided in this embodiment is different from the preferred embodiment 1 in that in this embodiment, the gear part 207 of the valve housing 200 is a conical hole, and the size of the conical hole is The diameter opening is located on the outside, and the maximum diameter of the conical hole is smaller than the inner diameter of the cavity 205 . In order to meet the design function of the structure itself, the maximum diameter of the conical hole needs to be larger than the diameter of the shaft body 102 of the mandrel 100 and smaller than the maximum outer diameter of the mouth portion 101 of the mandrel 100 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com