Nuclear power plant waste liquid treatment device performance verification method

A verification method and waste liquid treatment technology, applied in measurement devices, nuclear engineering, radioactive purification, etc., can solve the problems of long performance acceptance method, incomplete verification, poor economy, etc., and achieve objective and accurate test results. Wide applicability and high test efficiency

Active Publication Date: 2021-06-01

CHINA NUCLEAR POWER ENG CO LTD

View PDF2 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0012] In order to solve the technical problems of long time-consuming, incomplete verification, insufficient convincing power, waste of resources, and poor economic efficienc

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

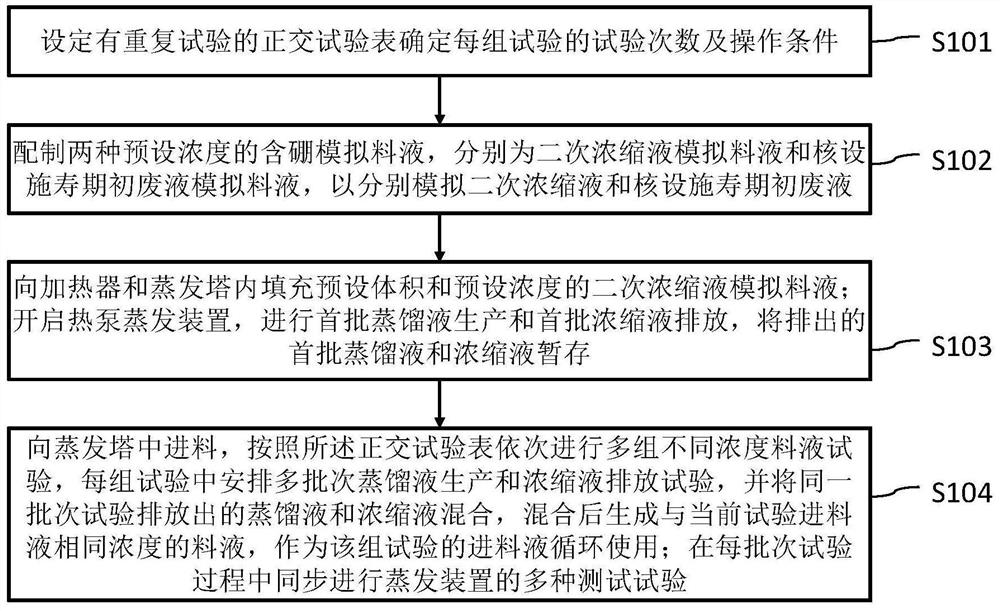

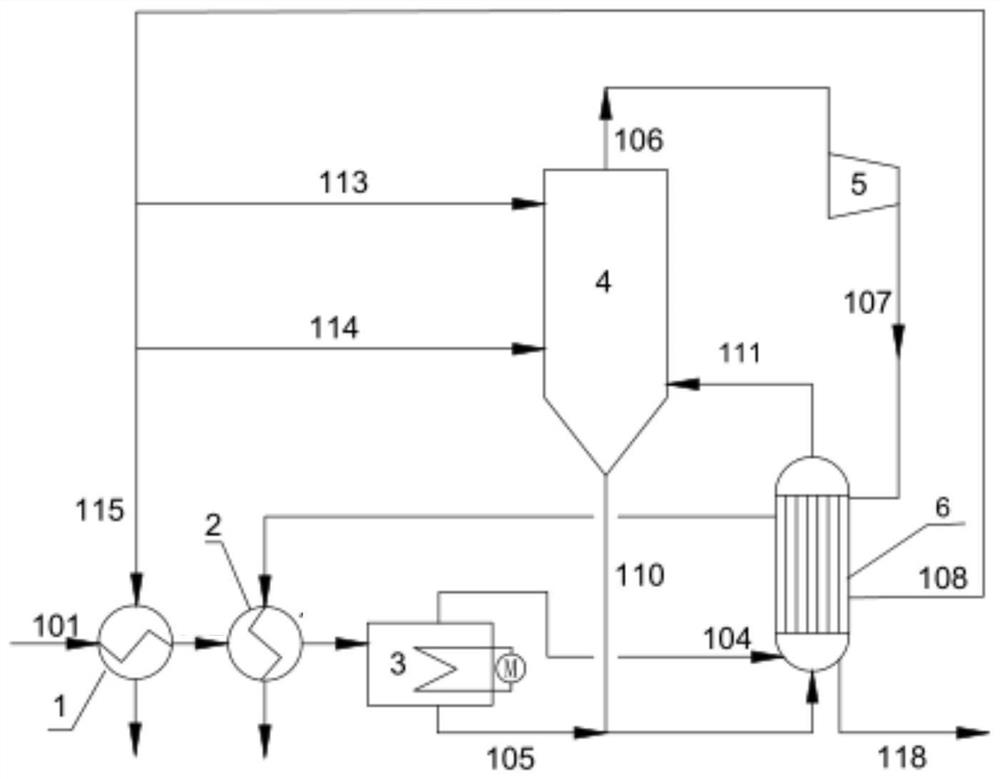

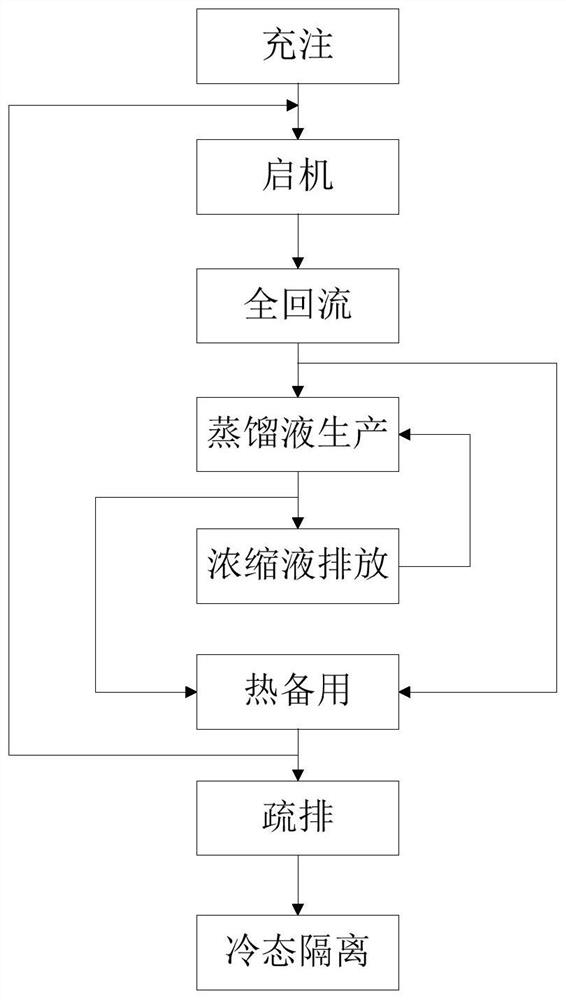

The invention provides a nuclear power plant waste liquid treatment device performance verification method which comprises the steps: carrying out an orthogonal test design, preparing a feed liquid with a preset boron concentration, and filling the device with the feed liquid; starting a heat pump evaporation device, returning the distillate flowing out of the evaporation tower to the evaporation tower, and discharging and temporarily storing the distillate after the distillate formed by the secondary steam meets a preset discharge requirement; when the concentrated solution reaches a preset discharge requirement, discharging the concentrated solution for temporary storage, and mixing the discharged distillate with the concentrated solution for recycling; sampling the distillate and the concentrated solution at regular intervals and measuring the boron concentration; and then testing feed liquids with different concentrations, and synchronously carrying out comprehensive tests on the evaporation separation decontamination performance, the energy-saving effect, the optimal design parameters and the operation stability of the radioactive waste liquid heat pump evaporation system. The verification method provided by the invention can reduce material liquid waste and equipment cost, shortens the first concentration time, synchronously performs multi-aspect tests, and has higher test efficiency.

Description

technical field [0001] The invention belongs to the technical field of nuclear power plant waste liquid treatment, and in particular relates to a performance verification method of a nuclear power plant waste liquid treatment device. Background technique [0002] Nuclear power plants will produce a large amount of boron-containing radioactive waste liquid during normal operation or under accident conditions and maintenance operations, such as process waste liquid, chemical waste liquid and coolant waste liquid, etc. If the boron-containing radioactive waste liquid is discharged directly, it will cause serious harm to the environment. At present, the commonly used waste liquid treatment method in nuclear power plants is to use the common evaporation process to treat the waste liquid. The more advanced treatment method for nuclear waste liquid treatment is heat pump evaporation radioactive waste liquid treatment technology. In recent years, heat pump evaporation has become a ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N33/00G21F9/08

CPCG01N33/00G21F9/08

Inventor 张志银高瑞发叶欣楠张川王艺霖李敏赵瀛刘佳惠刘金玲王成伟马艳玲

Owner CHINA NUCLEAR POWER ENG CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com