Method for measuring thickness of boundary layer

A technology for thickness measurement and boundary layer, which is applied in the field of aerodynamics in the aerospace industry, and can solve problems such as large measurement errors and limited number of measurement points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

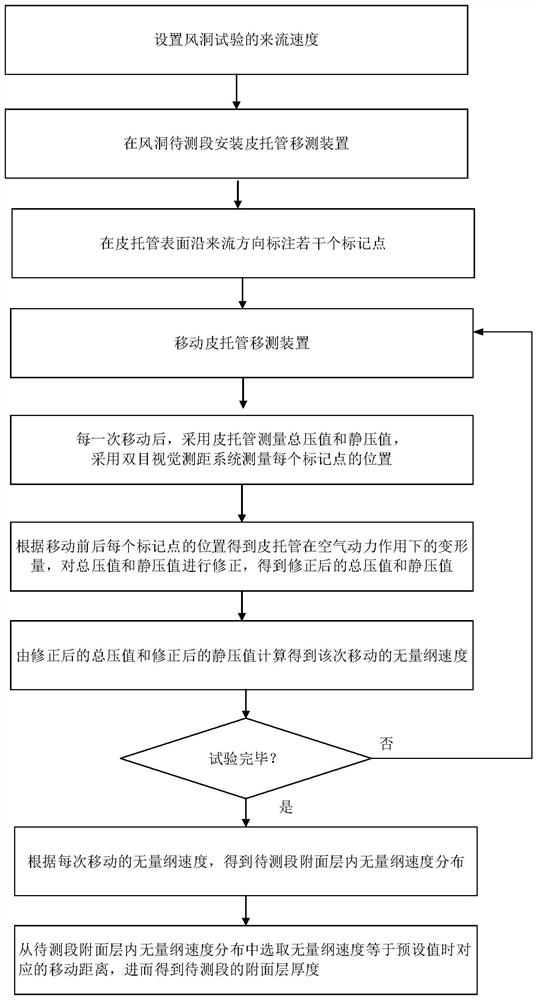

[0045] Embodiment 1 of the present invention is the measurement of the thickness of the boundary layer on the side wall of a certain transonic wind tunnel test section. The thickness of the boundary layer is measured by the method proposed by the present invention based on the moving pitot tube and binocular vision distance measurement. The specific process is as follows:

[0046] Step 1) Fix the pitot tube on the bracket on the side wall of the wind tunnel test section, and the bracket can move freely perpendicular to the side wall of the test section.

[0047] A pitot tube bracket is processed and installed at the measurement position of the boundary layer thickness on the side wall of the wind tunnel test section. The support can move freely in the direction perpendicular to the side wall by motor or other means.

[0048] Step 2) Paste or spray a plurality of special marking points for binocular vision ranging on the pitot tube surface along the flow direction.

[0049] 3-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com