A method for measuring the thickness of the boundary layer

A technology of thickness measurement and boundary layer, which is applied in the field of aerodynamics in the aerospace industry, can solve the problems of limited number of measurement points and large measurement errors, and achieve the effects of improving measurement accuracy, reducing measurement errors, and small flow field interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

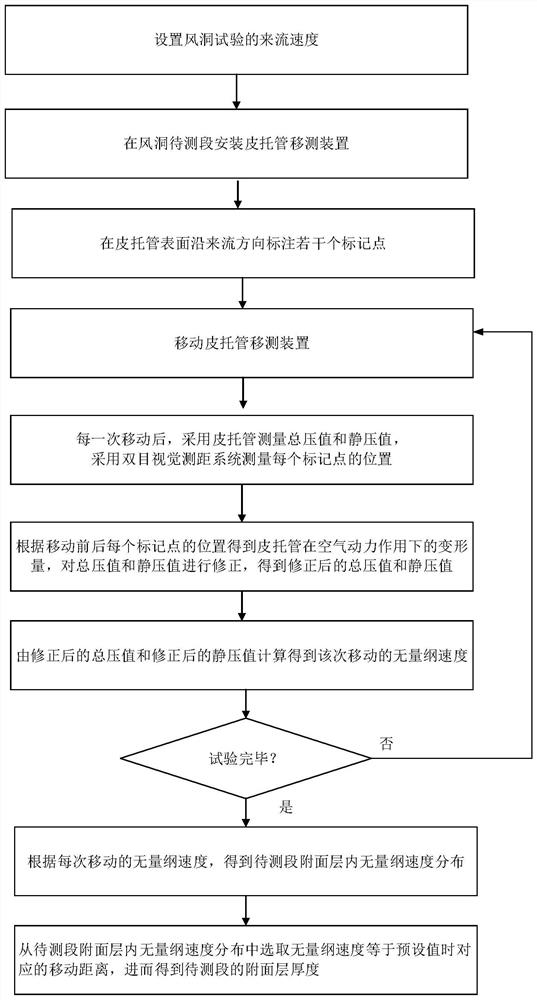

Method used

Image

Examples

Embodiment 1

[0047] A pitot tube bracket is processed and installed on the measurement position of the sidewall boundary layer thickness of the wind tunnel test section. stand can

[0048] Step 2) paste or spray a plurality of special marking points for binocular vision ranging along the flow direction on the surface of the pitot tube.

[0049] On the surface of the pitot tube, 3-5 special marking points for binocular vision ranging are arranged along the flow direction. Markers can be picked

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com