Cast bearing ring taking-out device

A technology for taking out devices and bearing rings, applied in the direction of lifting devices, crowbars, etc., can solve problems such as prone to accidents and dangers, and achieve the effects of reducing threats, uniform distribution, and labor-saving movement of bearing rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

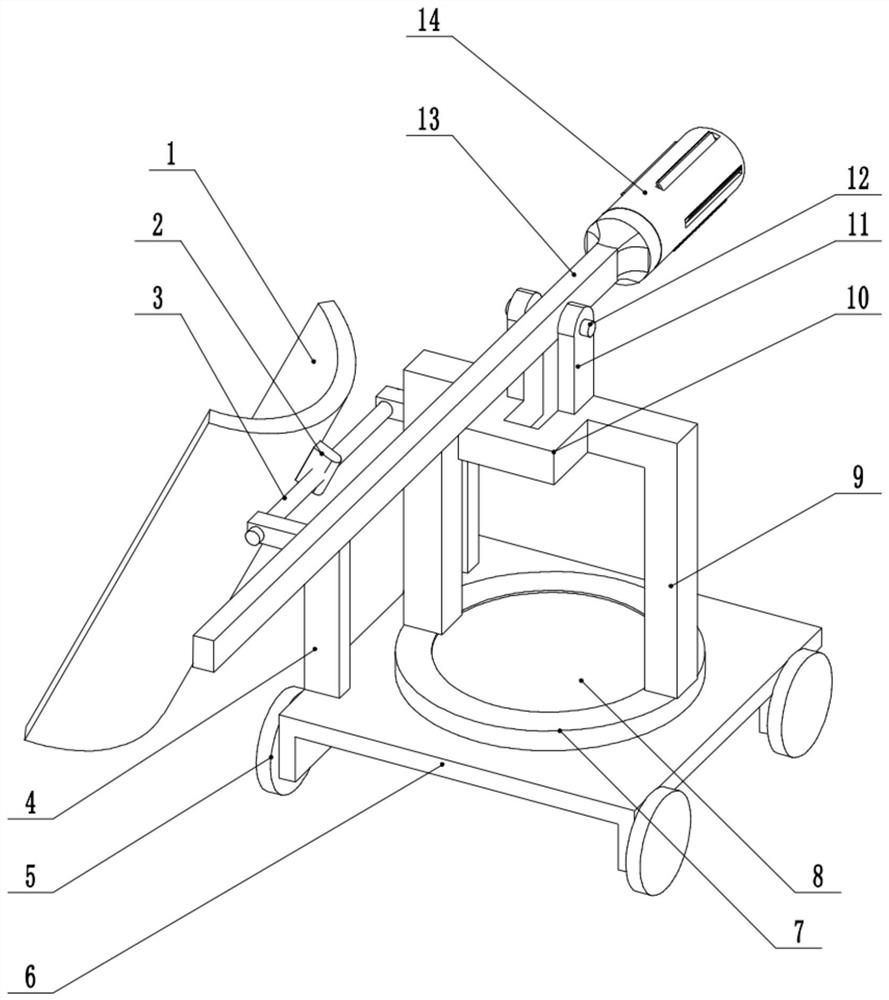

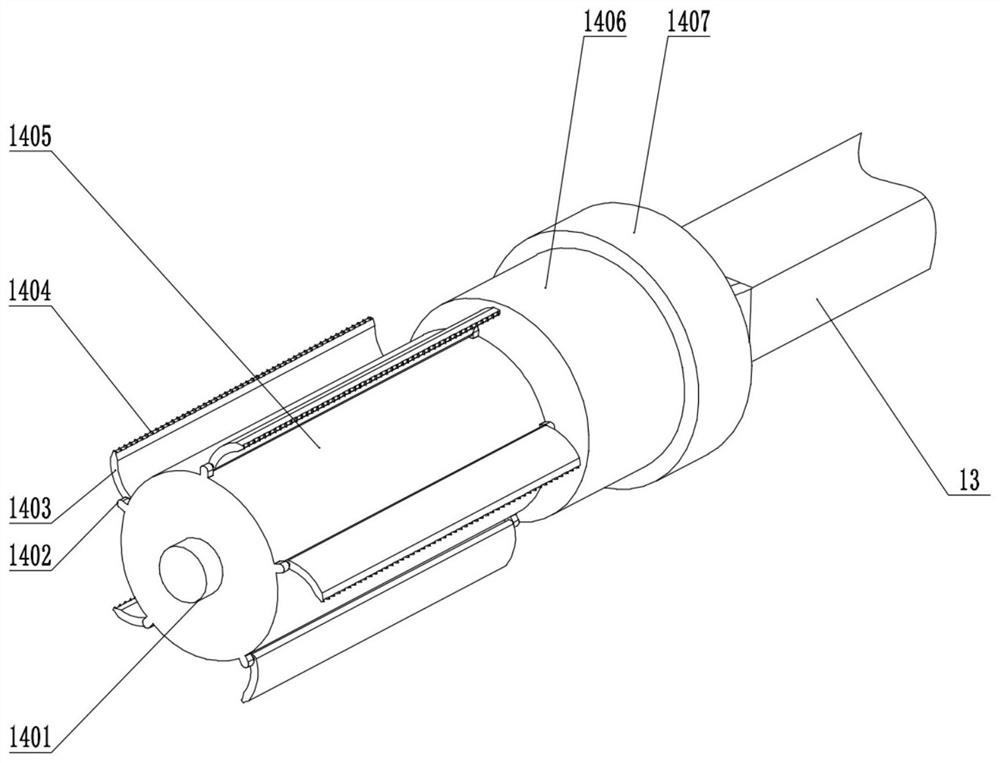

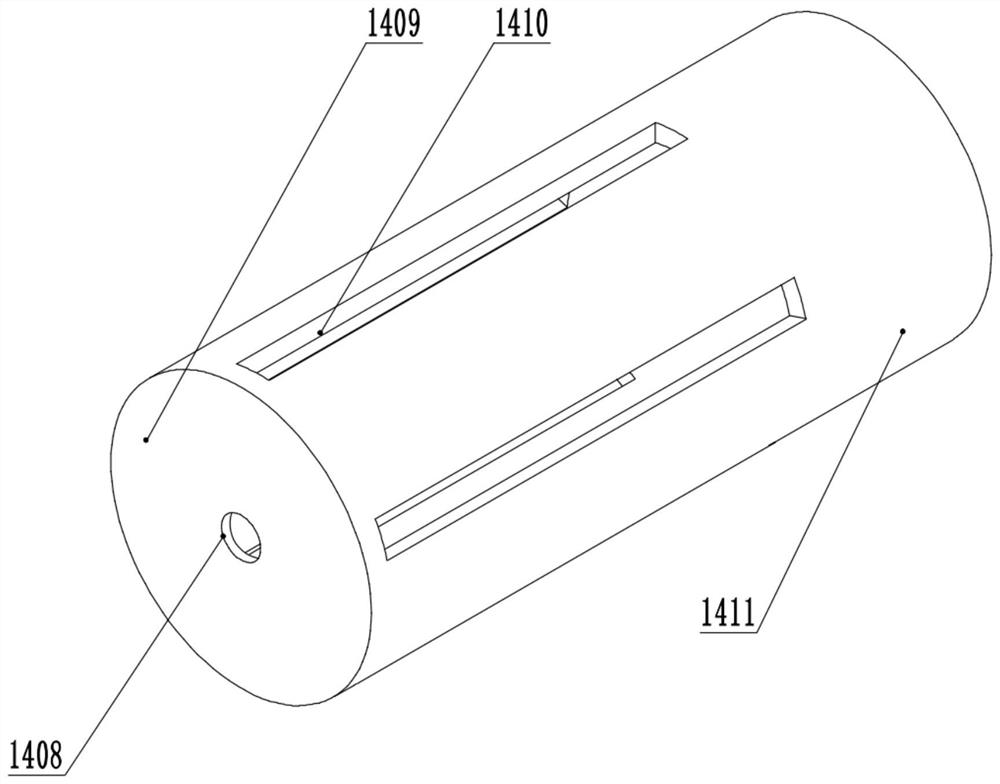

[0019] A casting bearing ring removal device, including a slide plate 1, a mounting block 2, a rotating shaft 3, a support frame 4, a wheel 5, a bottom plate 6, a turntable 7, a positioning rotating column 8, a support frame 2 9, a concave frame 10, and a support frame Three 11, rotating shaft 2 12, lever 13 and internal expansion assembly 14, the back of the slide plate 1 is provided with a mounting block 2, and the mounting block 2 is equipped with a rotating shaft 1 3, and the rotating shaft 1 3 is installed on the support frame, so The support frame one 4 is arranged on the base plate 6, the bottom of the base plate 6 is provided with a wheel 5, the middle position of the base plate 6 is provided with a positioning rotating column 8, and the outer circumference of the positioning rotating column 8 is equipped with a turntable 7, so The turntable 7 is provided with a support frame 2 9, the middle position of the support frame 2 9 is provided with a concave frame 10, the top ...

Embodiment 2

[0022] A casting bearing ring removal device, including a slide plate 1, a mounting block 2, a rotating shaft 3, a support frame 4, a wheel 5, a bottom plate 6, a turntable 7, a positioning rotating column 8, a support frame 2 9, a concave frame 10, and a support frame Three 11, rotating shaft 2 12, lever 13 and internal expansion assembly 14, the back of the slide plate 1 is provided with a mounting block 2, and the mounting block 2 is equipped with a rotating shaft 1 3, and the rotating shaft 1 3 is installed on the support frame, so The support frame one 4 is arranged on the base plate 6, the bottom of the base plate 6 is provided with a wheel 5, the middle position of the base plate 6 is provided with a positioning rotating column 8, and the outer circumference of the positioning rotating column 8 is equipped with a turntable 7, so The turntable 7 is provided with a support frame 2 9, the middle position of the support frame 2 9 is provided with a concave frame 10, the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com