Efficient gravure printing process based on plastic film

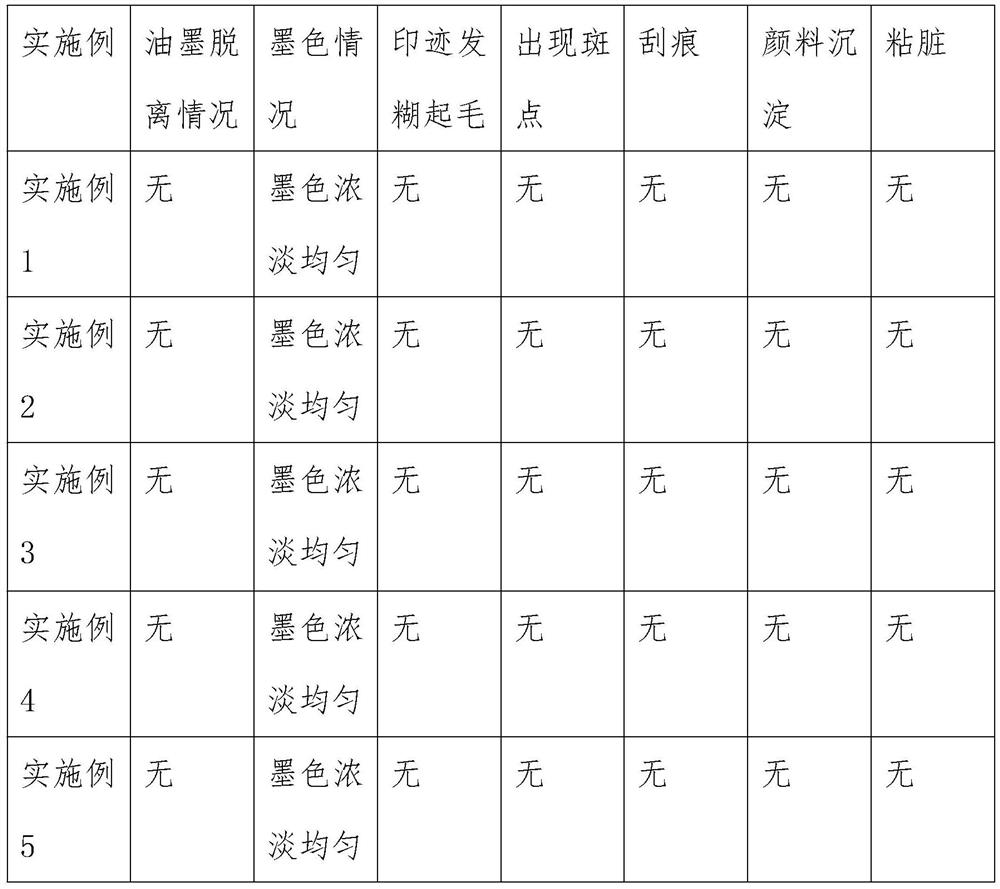

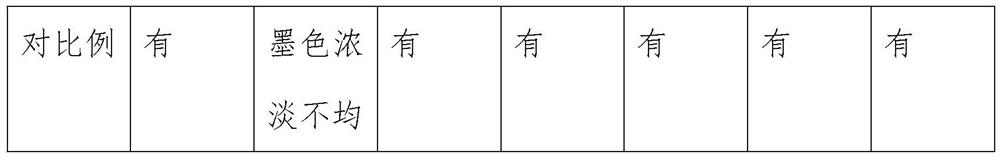

A plastic film and gravure printing machine technology, applied in printing, printing devices, inks, etc., can solve the problems of printing misalignment, wrong plate, water-based ink is not easy to dry, etc., to achieve high printing efficiency, good printing effect, ink color uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of high-efficiency gravure printing process based on plastic film proposed by the present invention comprises the following steps:

[0022] S1. Preparation before printing: Install the plastic film to be printed into the gravure printing machine, check whether there is any jamming in each part of the machine, and inject lubricating oil into the lubricating part;

[0023] S2. The plastic film to be printed passes through multiple printing units in sequence to print in different colors;

[0024] S3. Plate loading: install the printing plate cylinders in each color group according to the printing color sequence;

[0025] S4. Adjust the squeegee on the rule: After the pre-printing preparations are completed, carefully calibrate the printing plate, check the paper feeding, feeding, receiving, and push-pull rules, and make appropriate adjustments to correct the pressure. The hard knife linings are overlapped and placed in the middle of the upper and lower clamping pla...

Embodiment 2

[0029] A kind of high-efficiency gravure printing process based on plastic film proposed by the present invention comprises the following steps:

[0030] S1. Preparation before printing: Install the plastic film to be printed into the gravure printing machine, check whether there is any jamming in each part of the machine, and inject lubricating oil into the lubricating part;

[0031] S2. The plastic film to be printed passes through multiple printing units in sequence to print in different colors;

[0032] S3. Plate loading: install the printing plate cylinders in each color group according to the printing color sequence;

[0033] S4. Adjust the squeegee on the rule: After the pre-printing preparations are completed, carefully calibrate the printing plate, check the paper feeding, feeding, receiving, and push-pull rules, and make appropriate adjustments to correct the pressure. The hard knife linings are overlapped and placed in the middle of the upper and lower clamping pla...

Embodiment 3

[0037] A kind of high-efficiency gravure printing process based on plastic film proposed by the present invention comprises the following steps:

[0038] S1. Preparation before printing: Install the plastic film to be printed into the gravure printing machine, check whether there is any jamming in each part of the machine, and inject lubricating oil into the lubricating part;

[0039] S2. The plastic film to be printed passes through multiple printing units in sequence to print in different colors;

[0040] S3. Plate loading: install the printing plate cylinders in each color group according to the printing color sequence;

[0041] S4. Adjust the squeegee on the rule: After the pre-printing preparations are completed, carefully calibrate the printing plate, check the paper feeding, feeding, receiving, and push-pull rules, and make appropriate adjustments to correct the pressure. The hard knife linings are overlapped and placed in the middle of the upper and lower clamping pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com