Unit type multicolor printing machine

A printing machine and unit-type technology, applied in printing machines, rotary printing machines, printing, etc., can solve the problems of low printing efficiency, inconvenience and slippery printing, and achieve the effects of improving efficiency, speeding up, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

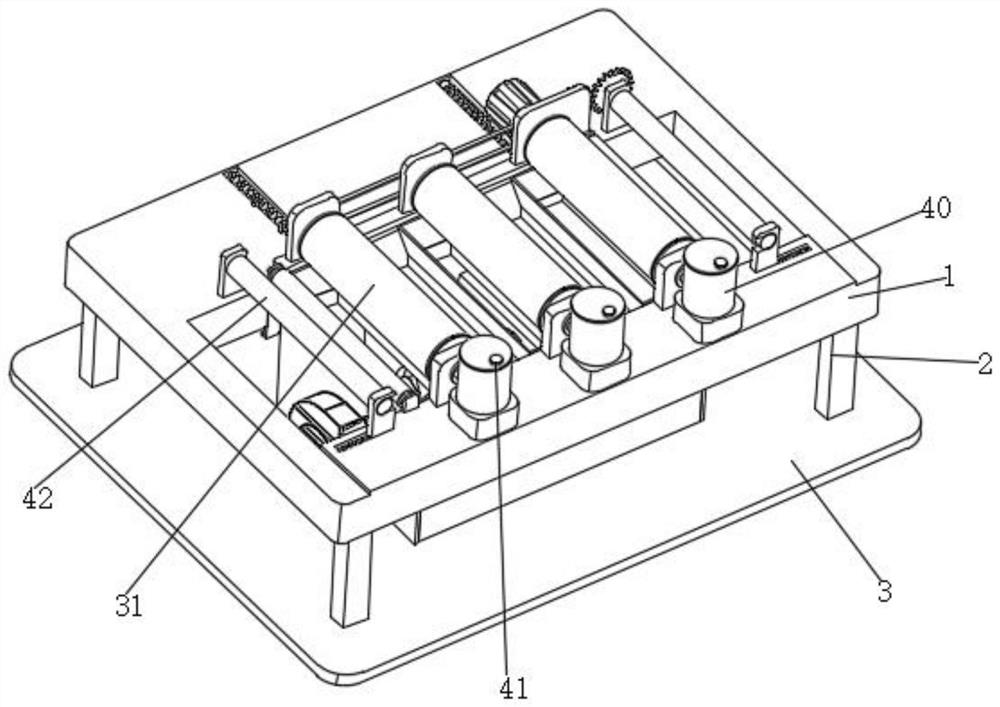

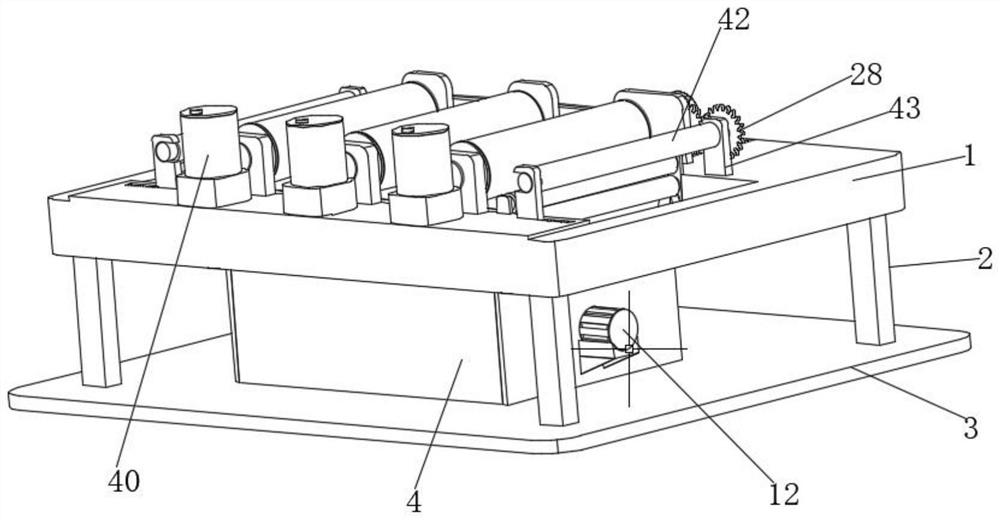

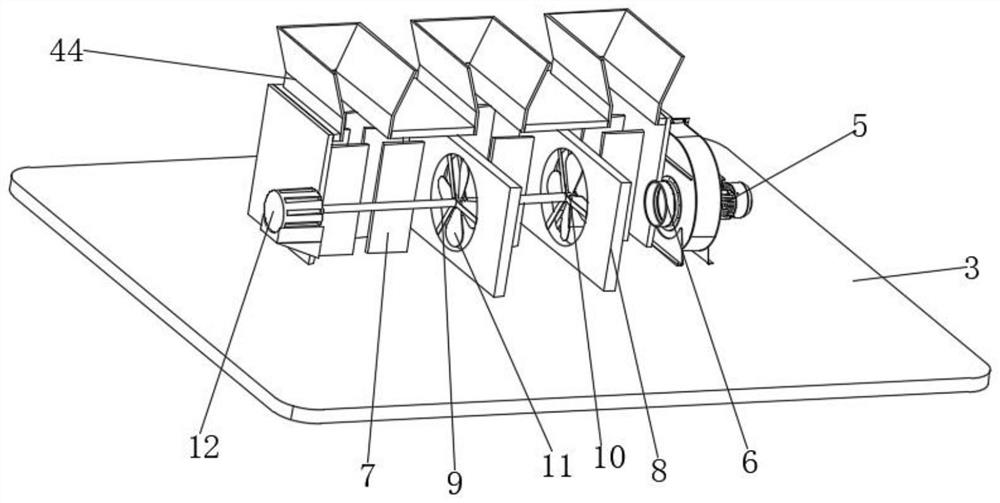

[0026] like Figure 1-Figure 8A unit-type multi-color printing machine shown includes a support frame 1, the four corners of the bottom of the support frame 1 are vertically connected with support columns 2, and the ends of the four support columns 2 away from the support frame 1 are connected horizontally with a bottom plate 3, The bottom plate 3 is provided with a drying mechanism near the support frame 1. The drying mechanism includes a drying box 4 connected horizontally to the bottom plate 3 near the support frame 1. The side of the drying box 4 away from the bottom plate 3 is provided with a material storage pipe 29. Corresponding to the air outlet 44, the interior of the drying box 4 is vertically an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com