Plastic granulating and screening all-in-one machine for plastic modification process

An all-in-one machine and dicing technology, which is used in the separation of solids from solids by air flow, solid separation, chemical instruments and methods, etc. It can solve the problems affecting the dicing working environment, the large amount of impurities in plastic particles, and the high noise of the granulating cavity. and other problems, to meet the needs of use, reduce labor, and effectively reduce noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

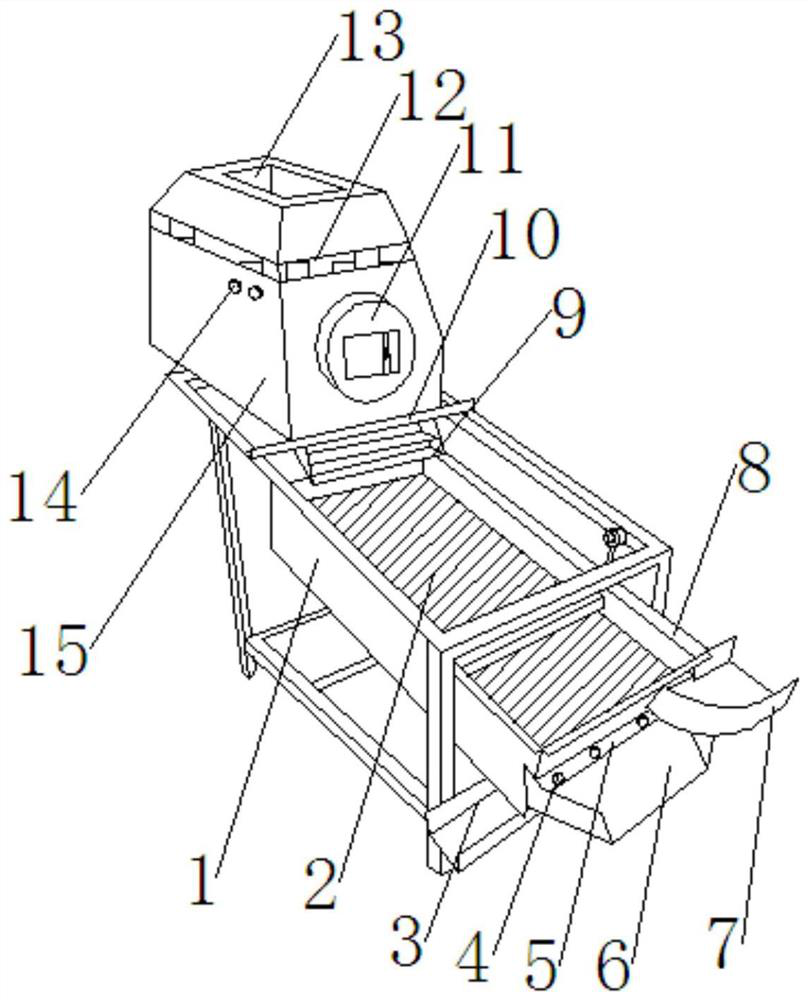

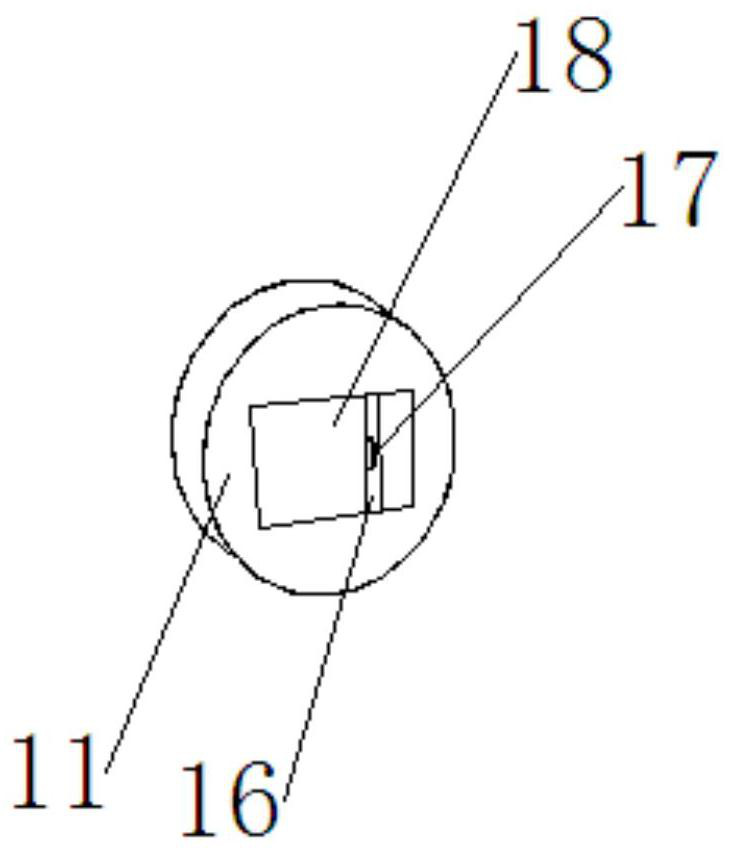

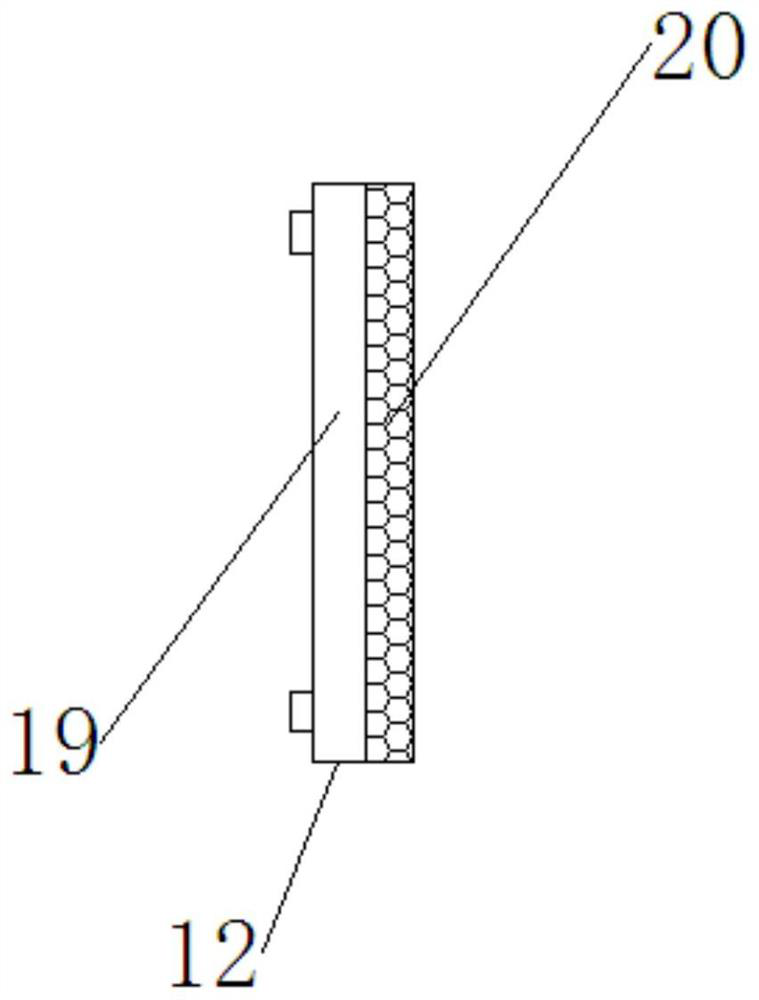

[0022] Example 1: See Figure 1-3 , the present invention provides a technical solution: a plastic pelletizing and screening integrated machine for plastic modification process, including an integrated machine body 1, a screen 2, a first discharge port 3, a fastening screw 4, a partition 5, a second Second discharge port 6, third discharge port 7, frame 8, double-layer suction port 9, beam 10, monitoring mechanism 11, noise reduction device 12, feed port 13, operation button 14, pelletizing chamber 15, moving slide 16. Pull ring 17, transparent liquid tank 18, sound insulation board 19 and sound-absorbing cotton 20, a screen 2 is provided inside the body 1 of the all-in-one machine, and a second discharge port 6 is provided at one end of the screen 2, and the second discharge One side of the mouth 6 is provided with a first discharge port 3, and the other side of the second discharge port 6 is provided with a third discharge port 7, and the top of the second discharge port 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com