Shaver head sliding positioning structure

A positioning structure and razor technology, applied in metal processing and other directions, can solve the problems of inconvenient use and poor cutting effect for users, and achieve the effects of increasing friction, reducing vibration, and avoiding changes in overlapping areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

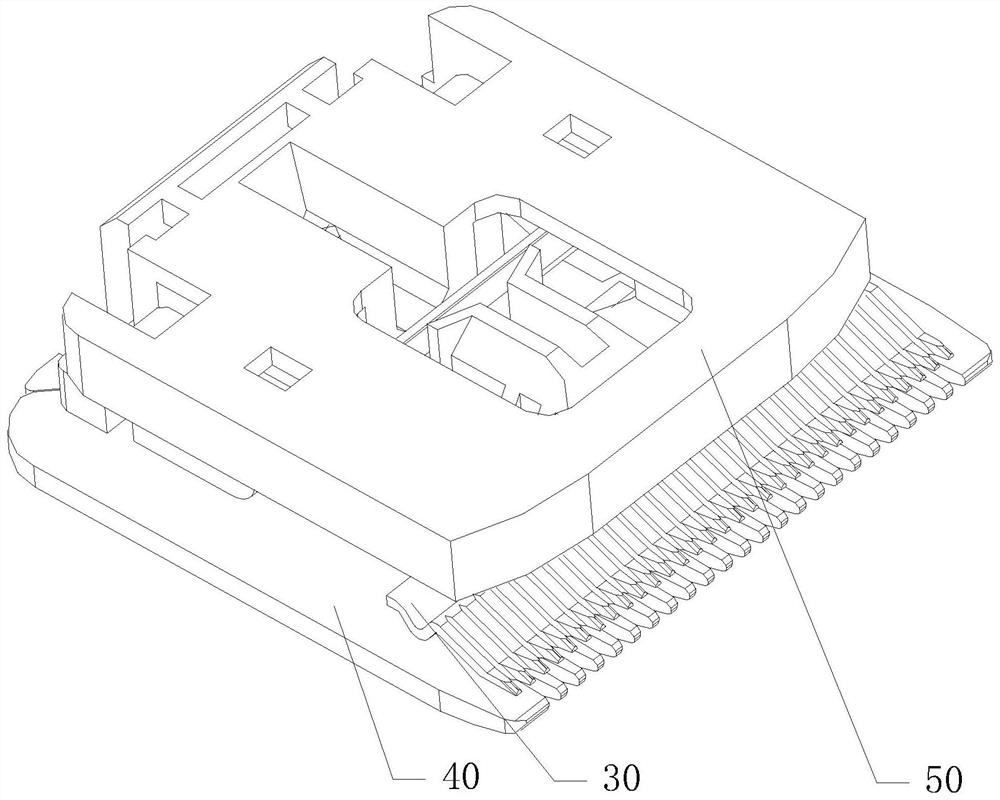

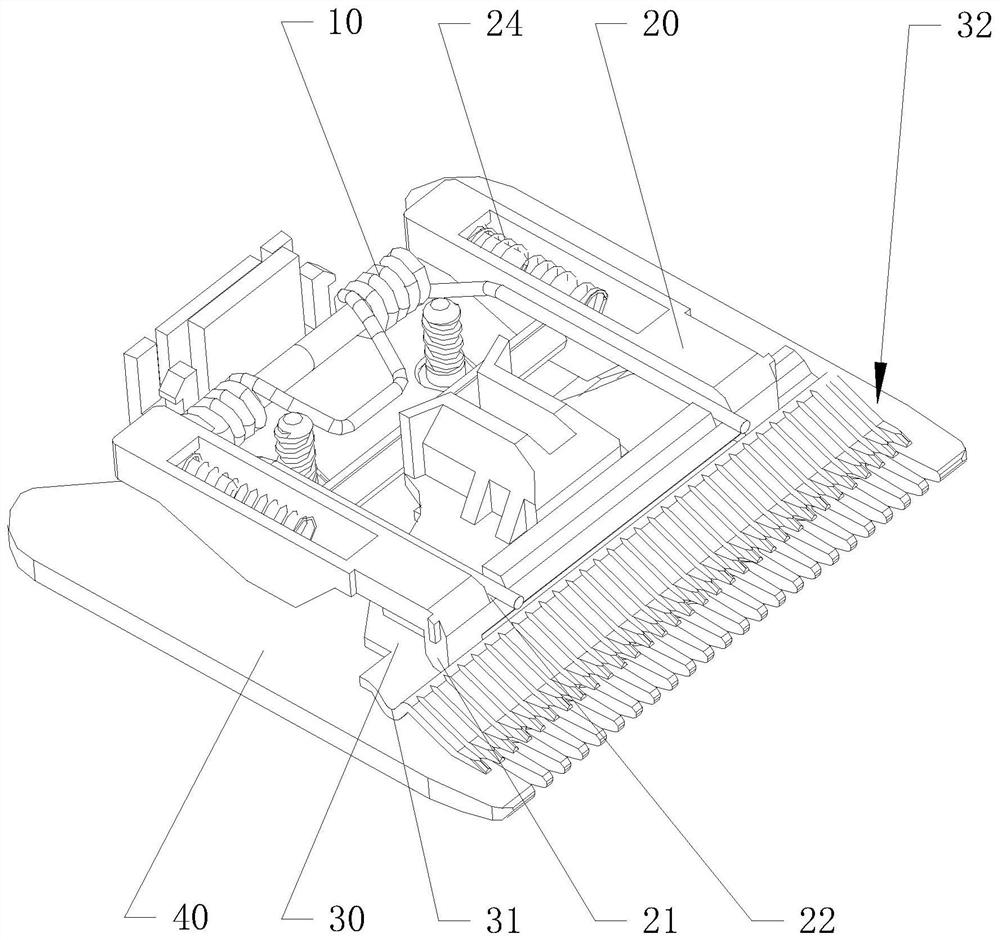

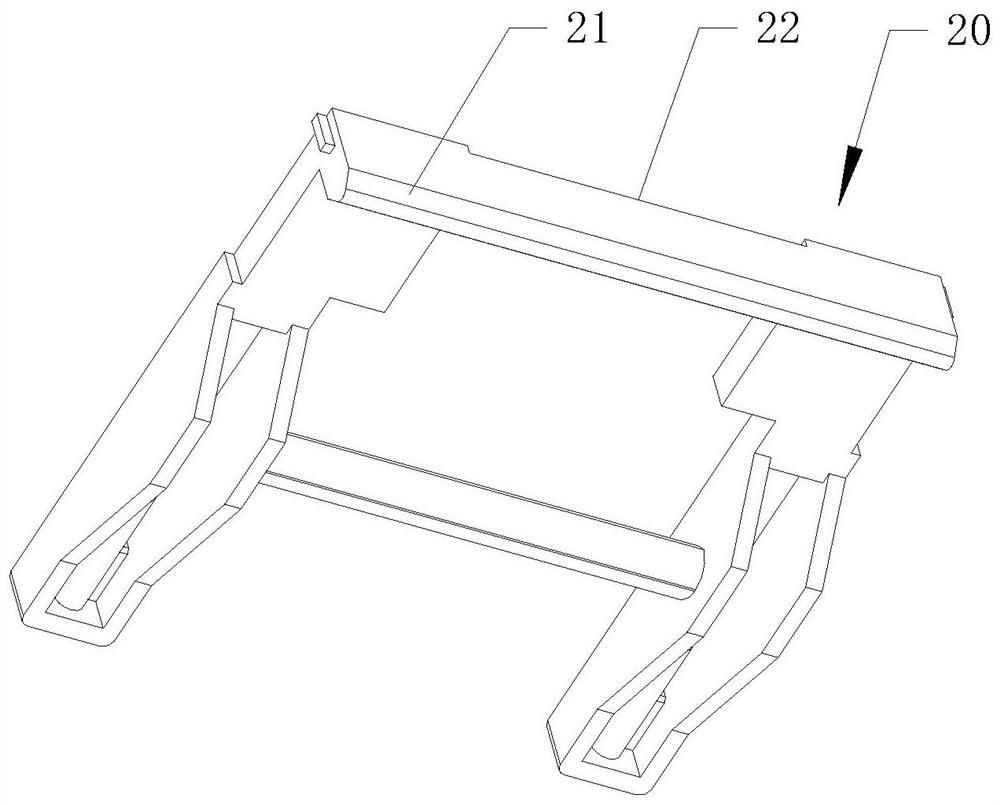

[0034] Please also refer to figure 1 , figure 2 as well as image 3 , the present embodiment discloses a sliding positioning structure of a shaver head, including a pressing member 10 , a blade assembly seat 20 , a moving blade 30 and a stationary blade 40 . The pressing member 10 is provided with a pressing end, and the bottom of the pressing end of the pressing member 10 is in contact with the top of the blade assembly seat 20 . The blade assembly seat 20 is provided with a moving blade positioning bar 21 , the moving blade positioning bar 21 points to the direction of the moving blade 30 , and the two ends of the moving blade positioning bar 21 are arranged toward both sides of the blade assembly seat 20 . The moving blade 30 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com