An automatic grasping and pre-twisting machine for mold adjusting thread nuts

A silk nut and die-adjusting technology, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of fixed installation environment of die-adjusting silk nut, high labor intensity of manual assembly, complicated device structure, etc., and achieve the clamping effect. Ideal, simple and reliable transmission structure, stable and reliable clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

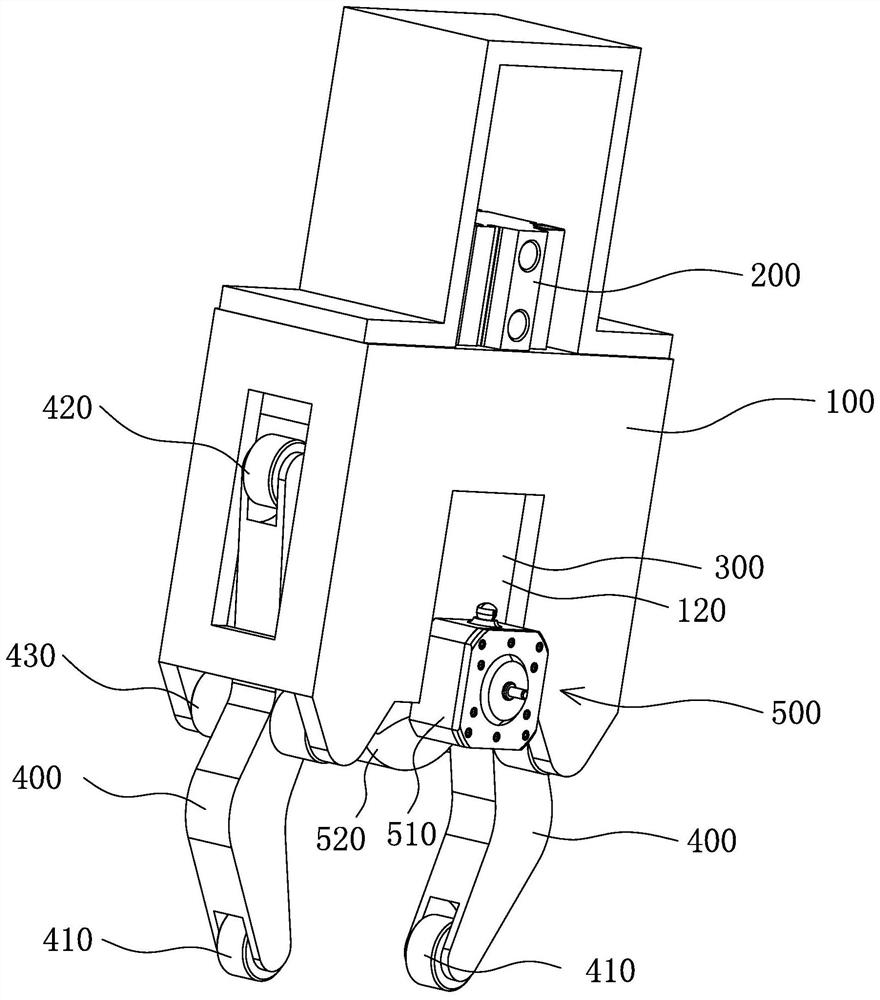

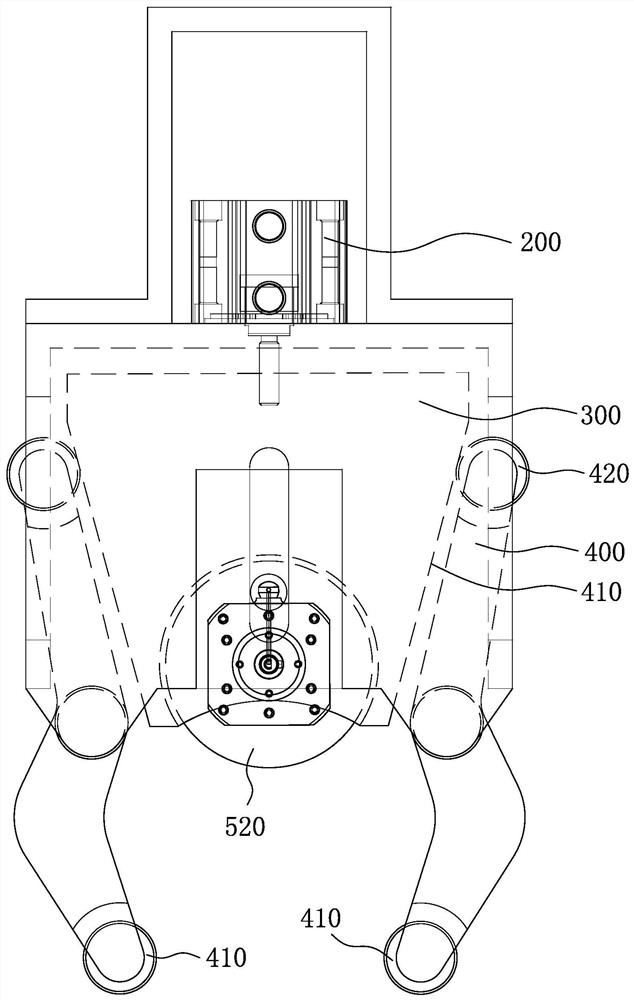

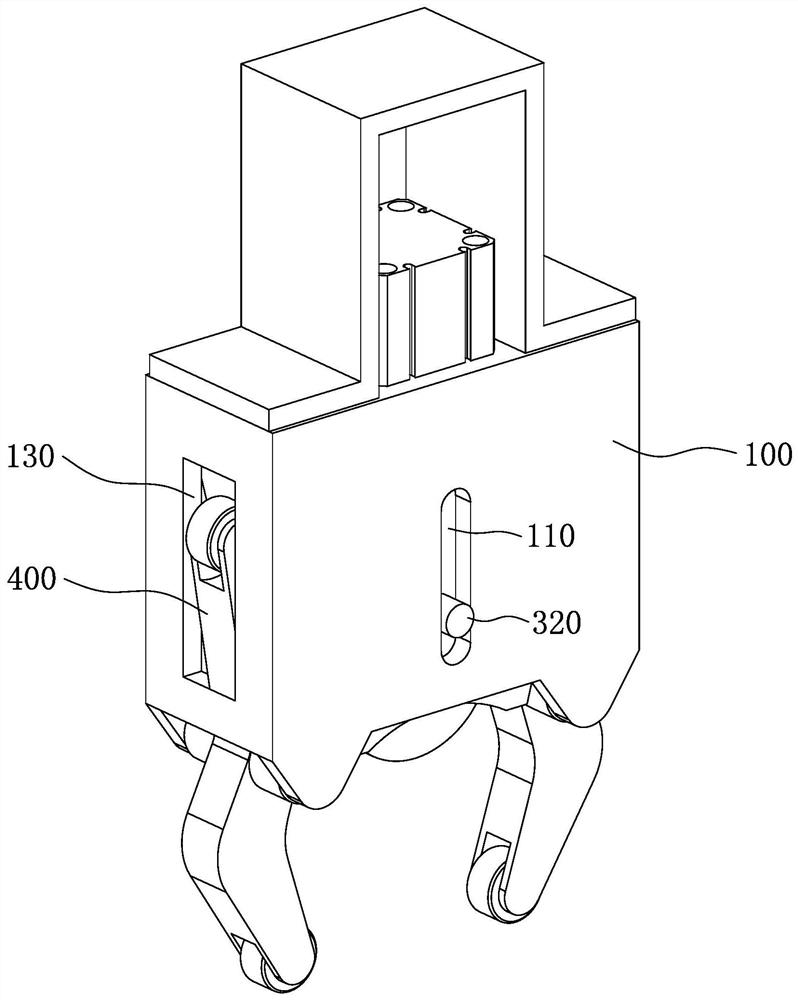

[0032] like Figure 1 to Figure 4 As shown, the automatic grasping and pre-twisting machine for mold adjusting nuts includes a clamping jaw housing 100 , a locking cylinder 200 , a driving block 300 , two crank clamping jaws 400 and a pre-tightening mechanism 500 .

[0033] The locking cylinder 200 is installed above the jaw housing 100, and the driving block 300 is inserted upward into the jaw housing 100 and connected with the locking cylinder 200. The locking cylinder 200 can drive the driving block 300 to slide up and down along the jaw housing 100. A crank jaw 400 is embedded upward into the jaw housing 100 and is separately arranged on both sides of the driving block 300. The middle part of each crank jaw 400 is hing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com