Coated sunscreen composition and sunscreen cream composed of same

A composition and technology of sunscreen, which are applied in the directions of skin care preparations, cosmetics, cosmetic preparations, etc., can solve the problem that the photostability and ultraviolet absorption ability cannot reach high-efficiency sunscreen and the like, and the photostability and ultraviolet absorption ability are improved. , PA value increase, SPF value increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1-A3 and comparative example B1-B8

[0039] Examples A1-A3 and Comparative Examples B1-B8: Preparation of Coated Sunscreen Composition

[0040] According to the proportioning in Table 1, ethylhexyl methoxycinnamate, hexyl diethylaminobenzoyl benzoate, ethylhexyl triazone, glyceryl stearate, steareth-21 , steareth-2, glycerin, hydrogenated castor oil, phenoxyethanol, methylparaben, and propylparaben are stirred and mixed uniformly to obtain a mixture; then, while homogenizing water, the above mixture is added to In water, control the homogenization speed to 3000r / min and continue homogenization for 3 minutes, then control the stirring speed to 3000r / min and stir to cool to room temperature, and then the coated sunscreen composition is obtained.

[0041] Each component distribution ratio (parts by weight) of Table 1 embodiment A1-A3 and comparative examples B1-B8

[0042]

Embodiment 1-3 and comparative example 1-6

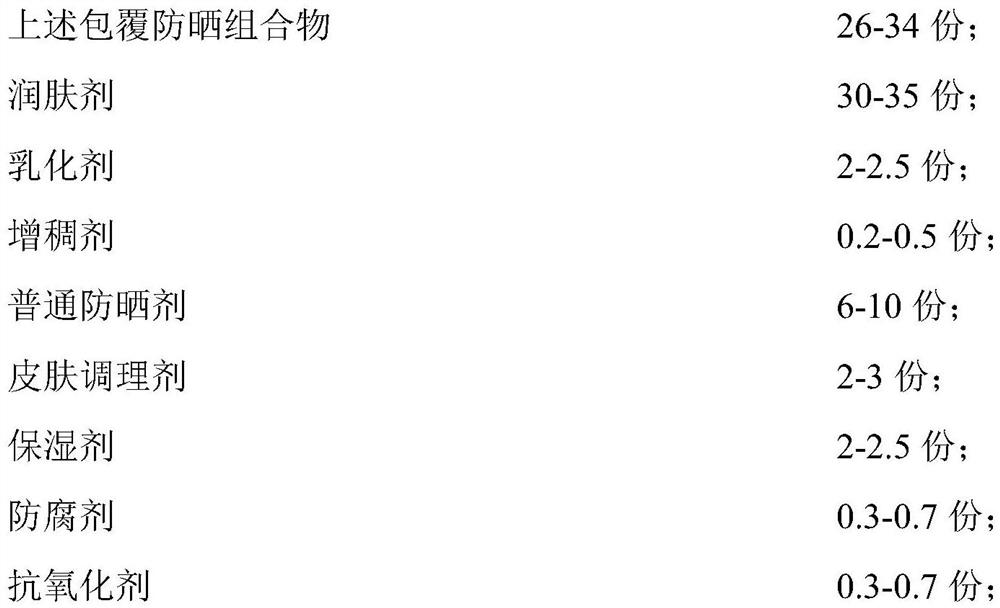

[0043] Embodiment 1-3 and comparative example 1-6: the preparation of sunscreen

[0044] 1) Add phase A [1, 2, 3, 4, 5, 6, 7, 8] raw materials into the main pot according to the formula in Table 2, stir and disperse evenly, and homogenize for 5 minutes;

[0045] 2) Add the raw materials of phase B [9, 10, 11, 12, 13, 14] into the side pot, stir to disperse and raise the temperature to 85°C, keep it warm for 20-30min and then cool down to below 40°C;

[0046] 3) Stir phase B [9, 10, 11, 12, 13, 14], add the raw materials of phase C [15, 16, 17, 18, 19, 20] into the side pot in turn, stir and disperse evenly;

[0047] 4) Slowly add the raw materials (phase B+C) in the side pot into the main pot, stir and disperse evenly, homogenize at a slow speed for 3-5 minutes, and keep the temperature at 25-30°C;

[0048] 5) Add the raw materials of phase D [21, 22, 23] into the main pot, and stir until the system is uniform;

[0049] 6) Self-inspect the board, pass it, and discharge; stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com