Acoustic system

A sound system and sound technology, applied in instruments, space heating and ventilation details, household heating and other directions, can solve problems such as difficult to change the relative relationship, reduce sound, equipment impact, etc., to eliminate wind noise, reduce pipe weight, The effect of eliminating fan noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

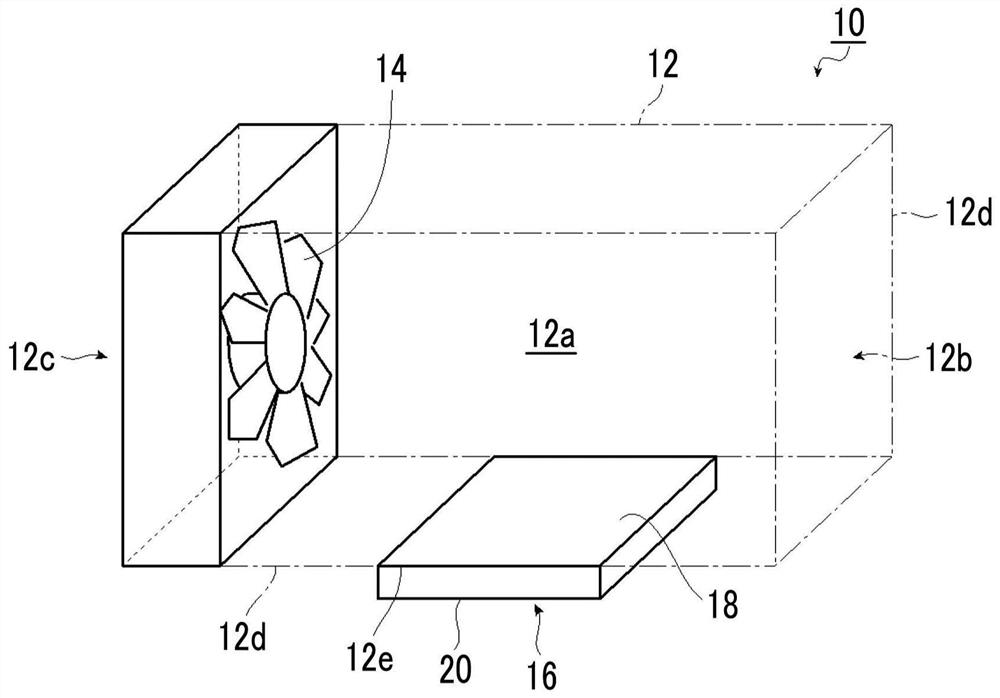

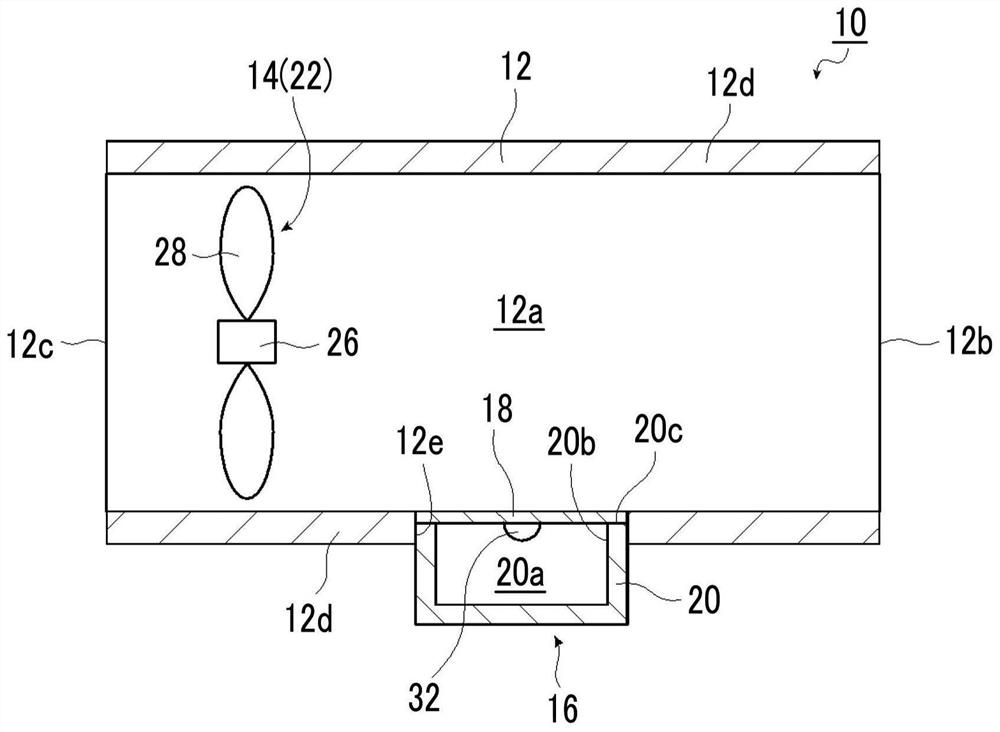

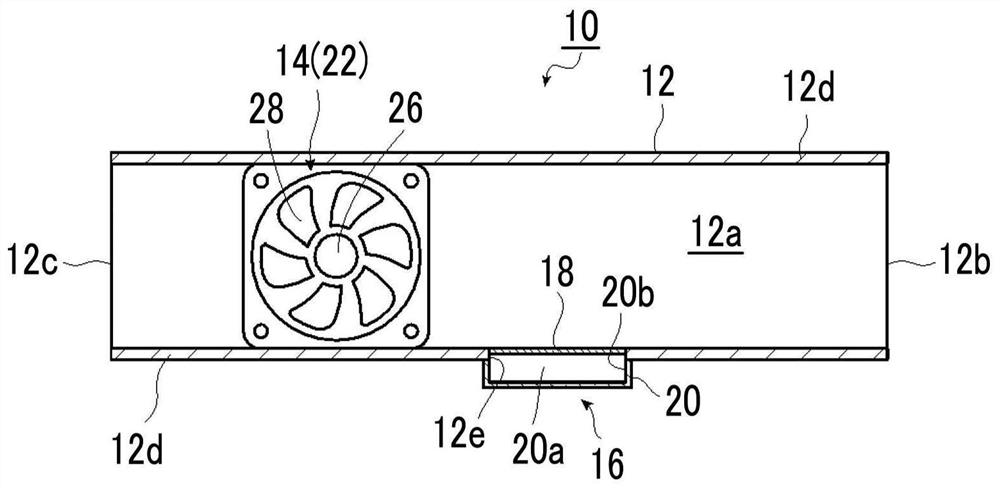

[0273] First, if Figure 37 and Figure 38 As shown, a through hole 12a having a square section of 60mm x 60mm has an overall dimension of 80mm x 80mm including a wall 12d with a thickness of 10mm, and the upper surface of one side end surface of the pipe 12 with a length of 145mm and two on the side, fitted separately Figure 38 The film-type resonator 16 of width 30mm × length 60mm × width 10mm is shown, thus constitutes Figure 37 The end face of one side of the pipe 12 is configured in cross-section. Next, a fan 14 having a square shape of 60 mm x 60 mm and a thickness of 28 mm is attached to one end surface of the duct 12 constructed in this way, and the fan 14 is configured to cover the through hole 12 a of the duct 12 to form the acoustic unit 10 .

[0274] Installed on the suction side of the fan 14 is a duct 13 having through holes 13a of the same size and lined with a polyurethane rubber 13b having a thickness of 10mm and having a cross-sectional dimension of 200m...

Embodiment 2

[0286]

[0287] It is the same measurement system as in Example 1, and the microphone 38 is arranged at a position at a distance of 100 mm at right angles from a position at a downstream side of 100 mm, instead of at a position at a position at a distance of at right angles of 140 mm from a position at a position at a downstream side of 200 mm.

[0288] The amount of current was adjusted so that the dominant sound of the fan 14 became 1500 Hz. At this time, the end wind speed measured by the flow meter was 7.8 m / s. The assay system was carried out with Figure 41A and Figure 41B The comparison of the acoustic unit 10a of Example 2 with the film resonator 16 shown, and the measurement system and Figure 42A and Figure 42B A comparison of the acoustic unit 50 of Comparative Example 1 including the Helmholtz resonator 52 shown.

[0289] As the film-type resonator 16 of the acoustic unit 10a of Embodiment 2, it is set as the following structure: on one surface in the secti...

Embodiment 3、 Embodiment 4

[0302] An experiment was carried out by arranging two rows (Example 3) and four rows (Example 4) of film-type resonators 16 instead of one row in the direction of the channel flow path in the same measurement system as in Example 2. , so as to obtain a greater noise reduction effect experiment. Figure 44 A schematic diagram of a configuration with 4 columns is shown in . show their results in Figure 45 .

[0303] Figure 45 The spectrum of the sound volume at the microphone position measured under the arrangement conditions of each film-type resonator 16 is shown in . Also, Table 1 shows a comparison of peak sound volumes, including the results of Example 2. It has been found that a greater noise reduction effect can be obtained by arranging a plurality of rows of film resonators 16 in the flow path direction of the pipe. When arranged in 4 rows, the noise reduction effect of more than 15dB can be obtained.

[0304] In addition, in Example 2, Example 3, and Example 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com