Testing device and method for testing thermal insulation effect of tunnel in cold region

A technology for effect testing and tunneling in cold regions, which is applied to measuring devices, testing of machine/structural components, instruments, etc. It can solve the problems of high cost and difficult testing of tunnel insulation facilities, and achieve low cost, simple structure and high accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

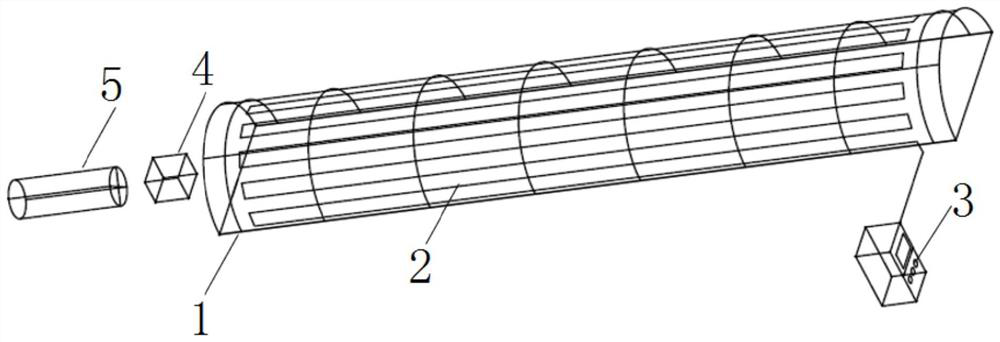

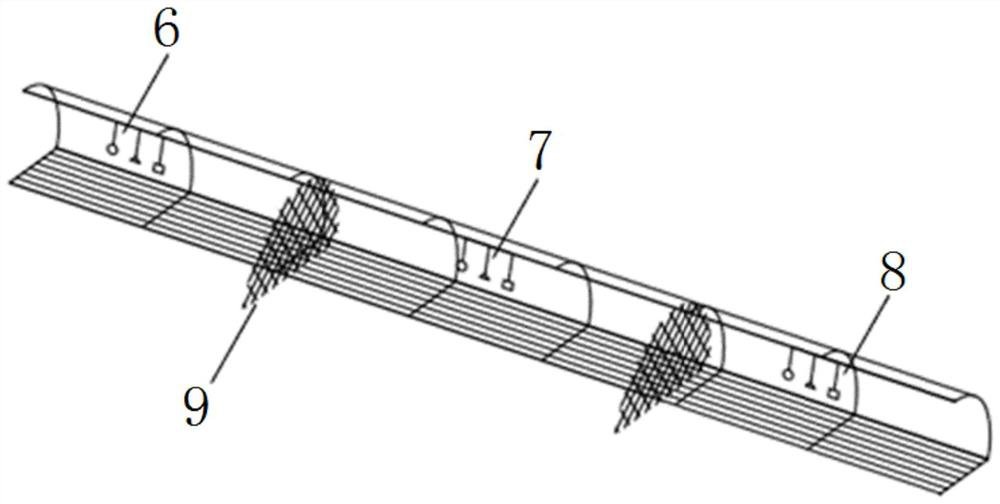

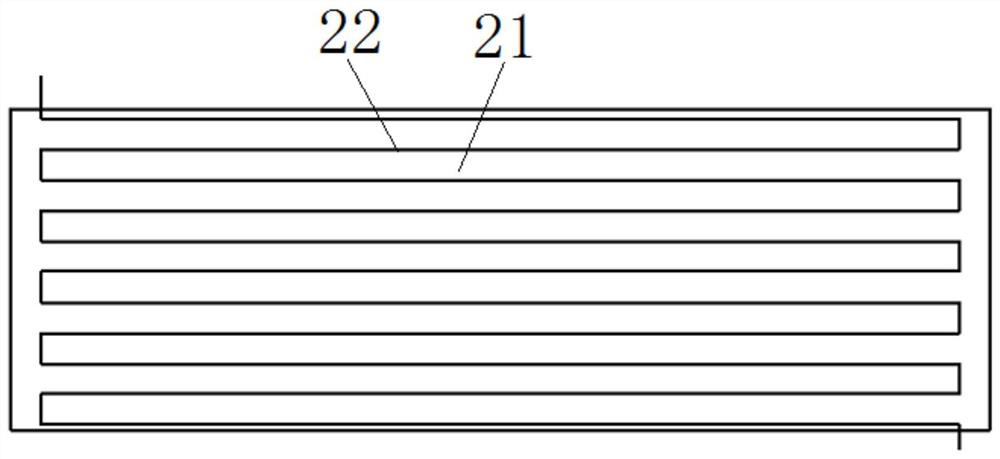

[0046]This embodiment provides a test device for a cold zone tunnel insulation effect, including a tunnel model 1, a electric heating heat heating layer 2, a temperature-temperature distribution box 3, a refrigeration device 4, a supply device 5, three sets of environments Acquisition device and two resistance grilles 9; Tunnel model 1 is made of acrylic plate, and the tunnel model 1 is fixedly disposed on the ground or the test stage, and the electric heating layer 2 is laid on the inner wall of the tunnel model 1, and heats heating Layers 2 include electric heating and geotextiles, electric heating tapes with a sponsole, bonding on geotextile, forming a whole thermal heating layer; model test, using heat heating layer 2 direct laying In the inner side of the lining of the tunnel model 1, the size is slightly smaller than the inner surface area of the arch wall portion of the tunnel model; the power supply end of the electric heating heat layer 2 is connected to the controlled po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com