Verification method and device for modal analysis of steam turbine rotor

A steam turbine rotor and modal analysis technology, applied in the field of steam turbines, can solve the problems of not being able to meet the modal accuracy requirements of steam turbine rotors, and the low pass rate of product tests, so as to improve the pass rate of tests, eliminate thermal bending, and stabilize the state of the rotor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Hereinafter, the present application will be described in detail with reference to the accompanying drawings and embodiments. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

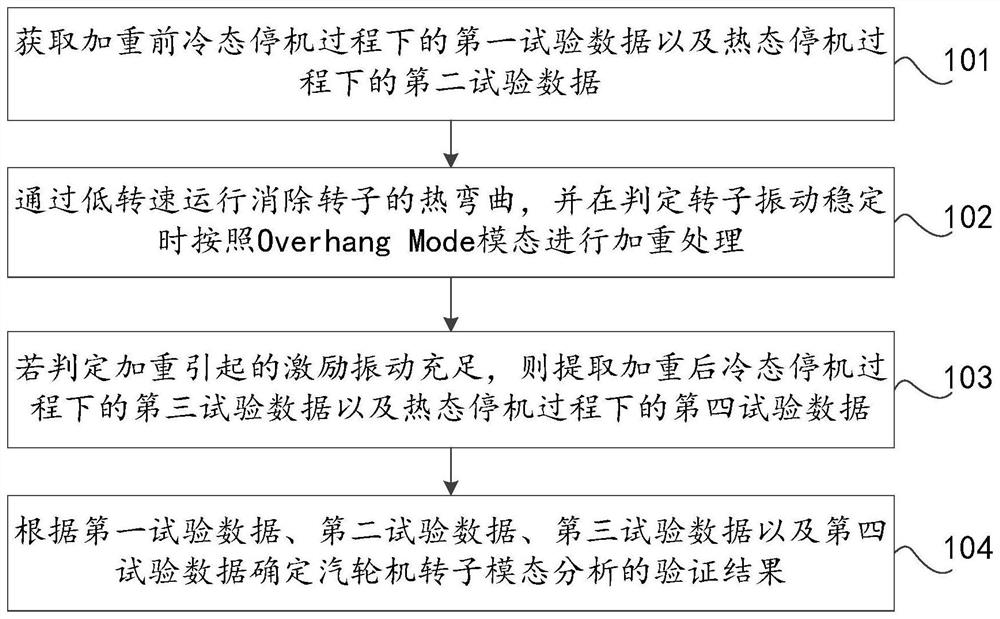

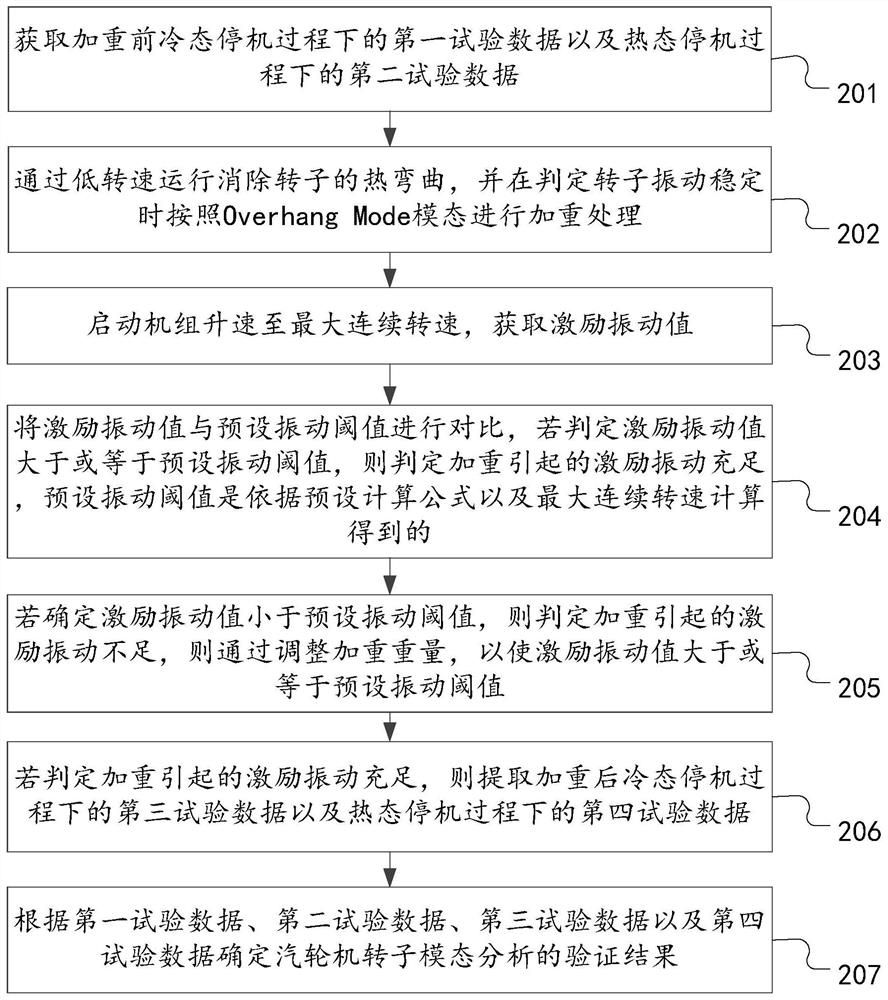

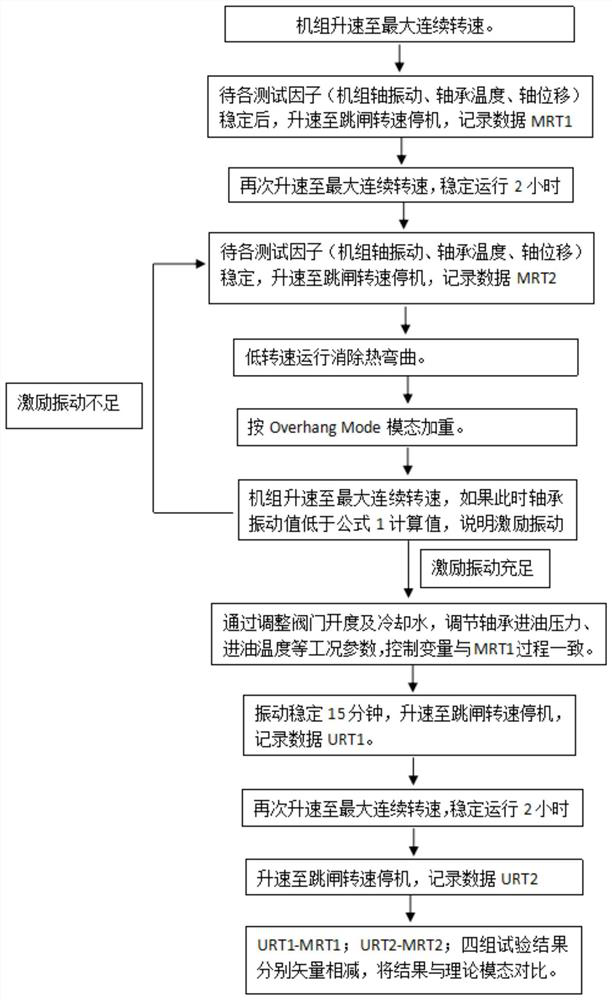

[0067] Aiming at the problem that the current modal analysis of the steam turbine rotor easily leads to a low test pass rate of the product and cannot meet the accuracy requirements of the analysis and verification of the steam turbine rotor modal, this embodiment provides a steam turbine rotor modal analysis method Authentication methods such as figure 1 As shown, the method includes:

[0068] 101. Acquire the first test data in the cold shutdown process before aggravation and the second test data in the hot shutdown process.

[0069] Wherein, the correspondence between the first test data and the second test data may be rotor vibration data before aggravation, which may include ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com