Non-contact magnetic sensor

A magnetic sensor, non-contact technology, applied in the field of sensors, can solve the problems of unable to adjust the pressure range of the sensor, inconvenient for fixed installation, unable to directly read the pressure value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

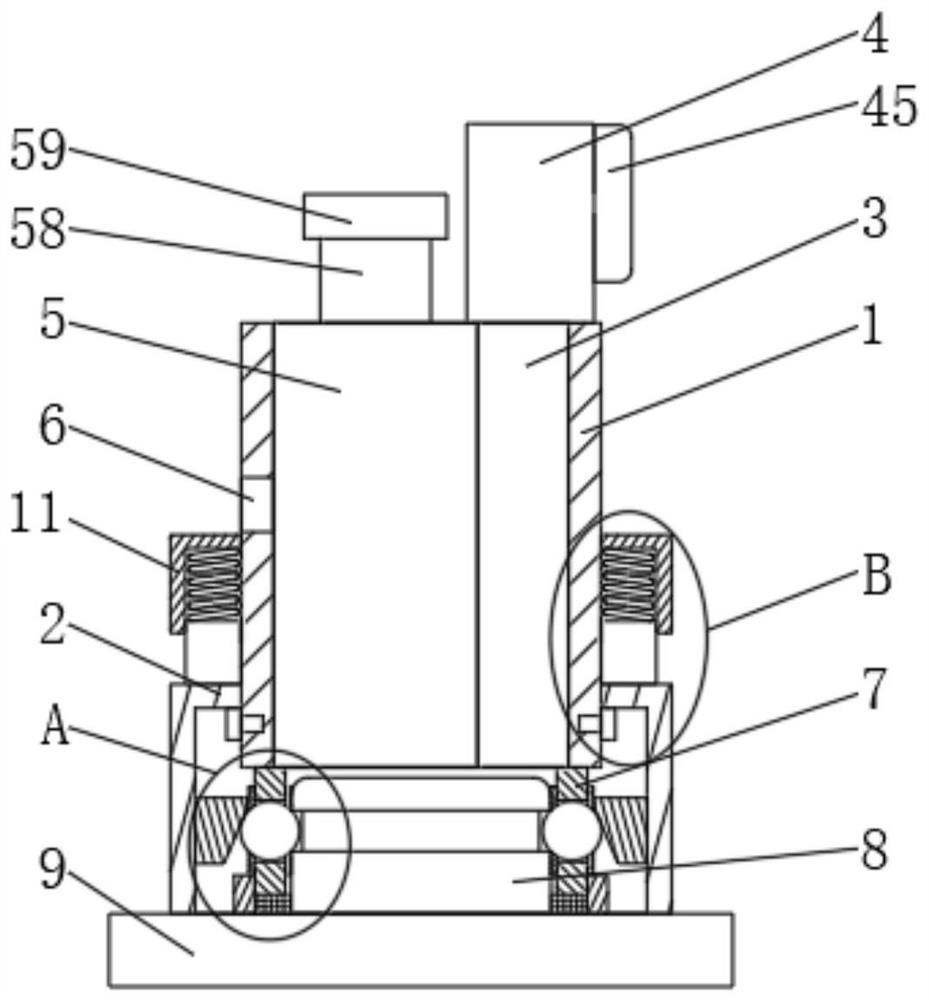

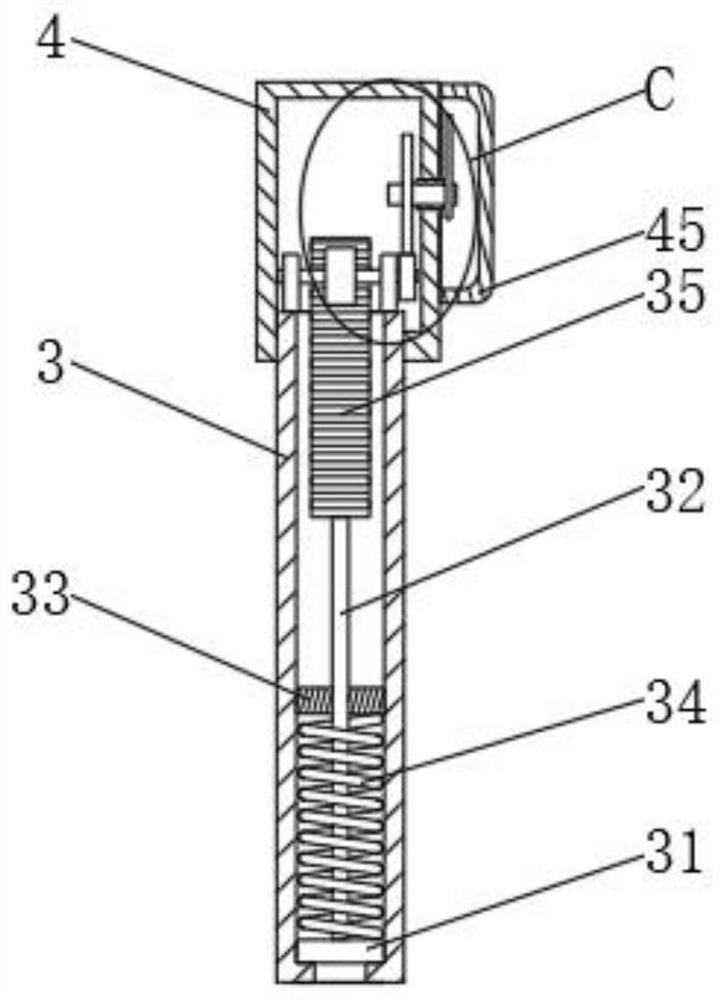

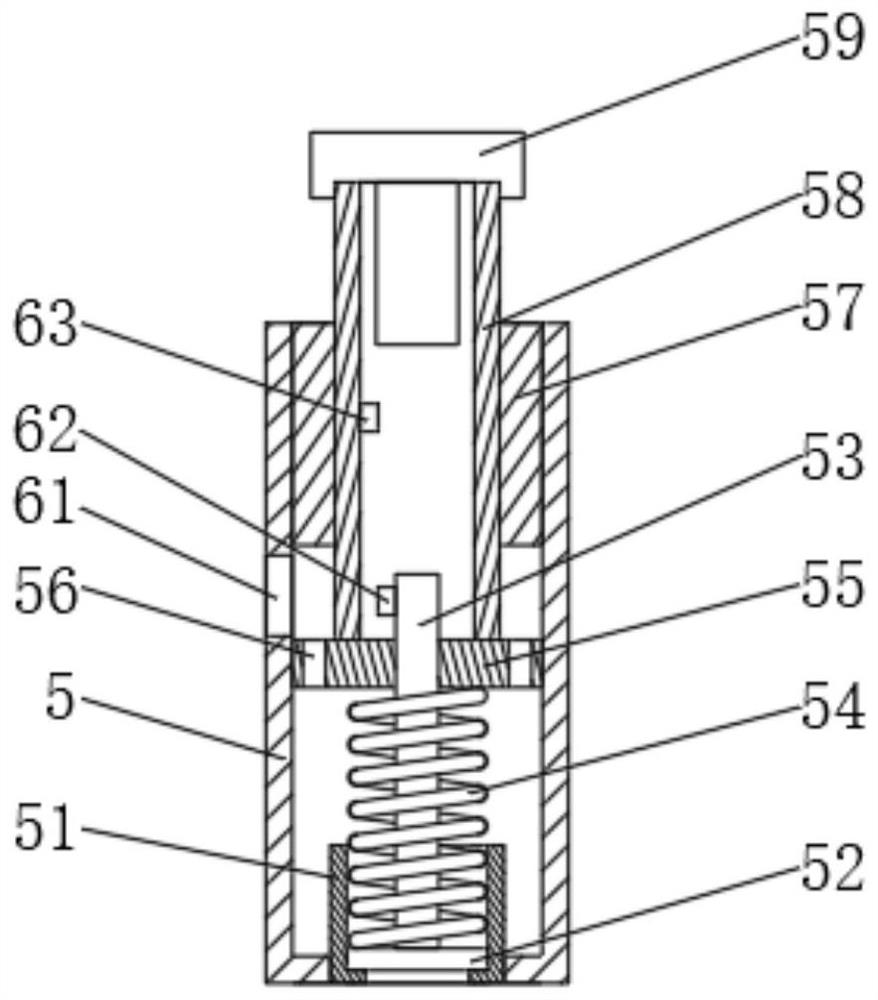

[0026] A non-contact magnetic sensor, including a housing 1, a sliding ring 2, a pressure gauge 3, a pressure box 4, an inductor 5, a vent hole 6, a connection port 7, a fixed port 8, a base 9, a slider 10 and Drive shaft 42, the outer side of the housing 1 is slidably connected with a sliding ring 2, the inner wall of the housing 1 is fixedly connected with a pressure gauge 3, and the upper end of the pressure gauge 3 is fixedly connected with a pressure tank 4, the housing An inductor 5 is fixedly connected to the inner wall of the body 1, and the right end of the inductor 5 is fixedly connected to the left end of the pressure gauge 3. The housing 1 is provided with a vent hole 6, and the housing 1 The lower end is fixedly connected with a connecting port 7, the inside of the connecting port 7 is clamped with a fixed port 8, the lower end of the fixed port 8 is fixedly connected with a base 9, and the lower end of the sliding ring 2 is in contact with the upper end of the bas...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap