Vibration and noise reduction compaction table

A technology of vibration reduction and noise reduction and vibration table, which is applied in the direction of spring/shock absorber, vibration suppression adjustment, mechanical equipment, etc., can solve the problems of high noise sound energy, difficulty of noise reduction, wide influence range, etc., and achieve reduction Effect of noise pollution, reduction of noise influence area, reduction of vibration and shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

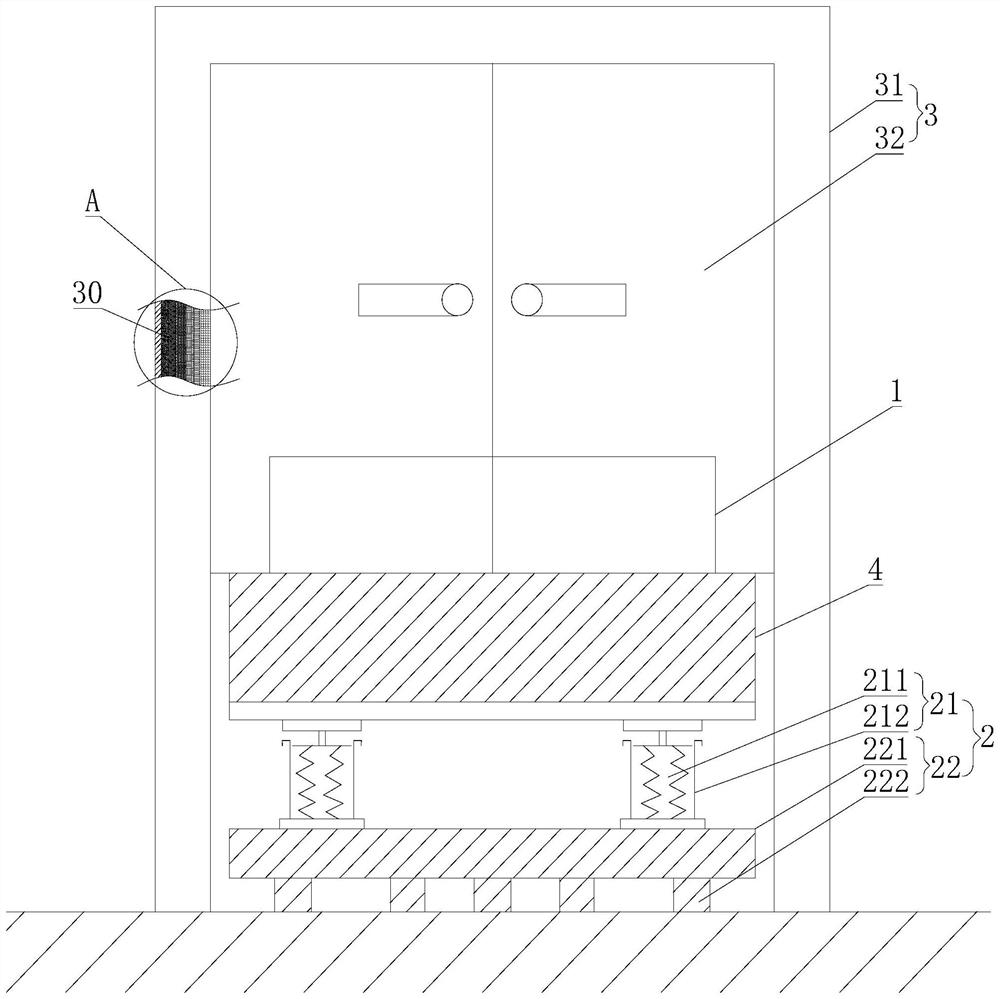

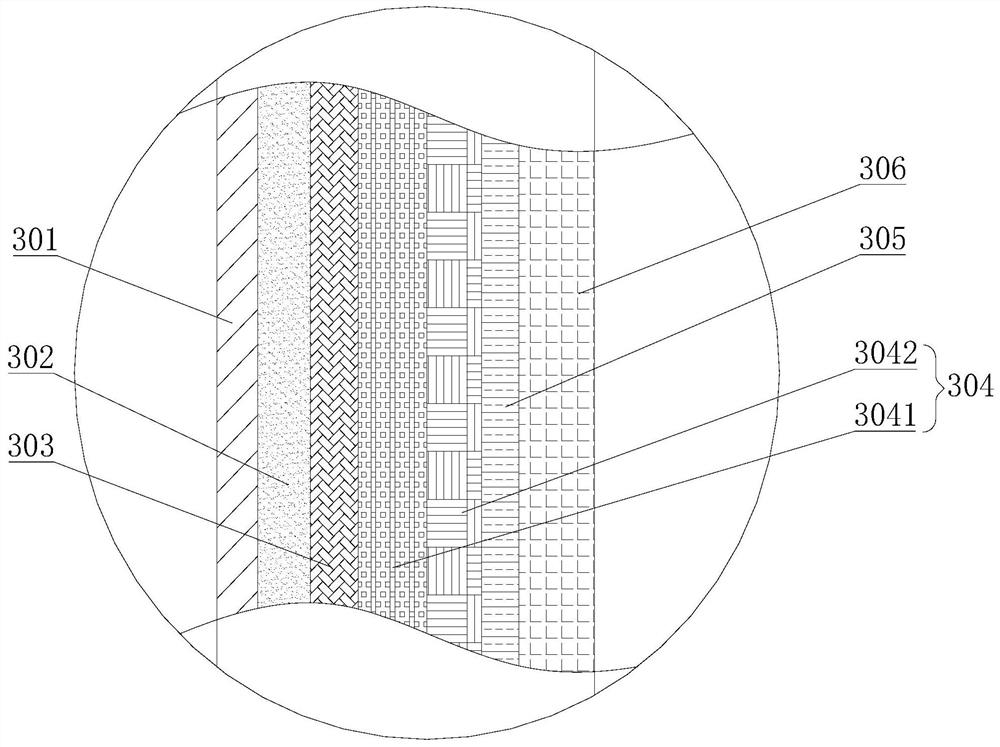

[0022] Such as figure 1 and figure 2 As shown, a vibrating platform capable of reducing vibration and noise provided in this embodiment includes a vibrating platform 1 for carrying a vibrating device and materials to be vibrated. In order to make the vibrating table reliably reduce vibration and noise, reduce noise pollution and noise influence range, further, the vibrating table that can reduce vibration and noise also includes a double-stage vibration-damping assembly 2, a sound-proof cover assembly 3 and a counterweight Platform 4, one end of the counterweight platform 4 is fixedly connected to the vibration platform 1, the other end of the counterweight platform 4 is fixedly connected to the double-stage vibration-damping assembly 2, the vibration platform 1, the double-stage vibration-damping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com