Climbing device of construction machinery

A kind of construction machinery and unified technology, applied in the direction of construction, building structure, scaffolding accessories, etc., can solve the problems of manual lifting to high places, achieve the effect of improving speed and safety, and increasing the force-bearing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

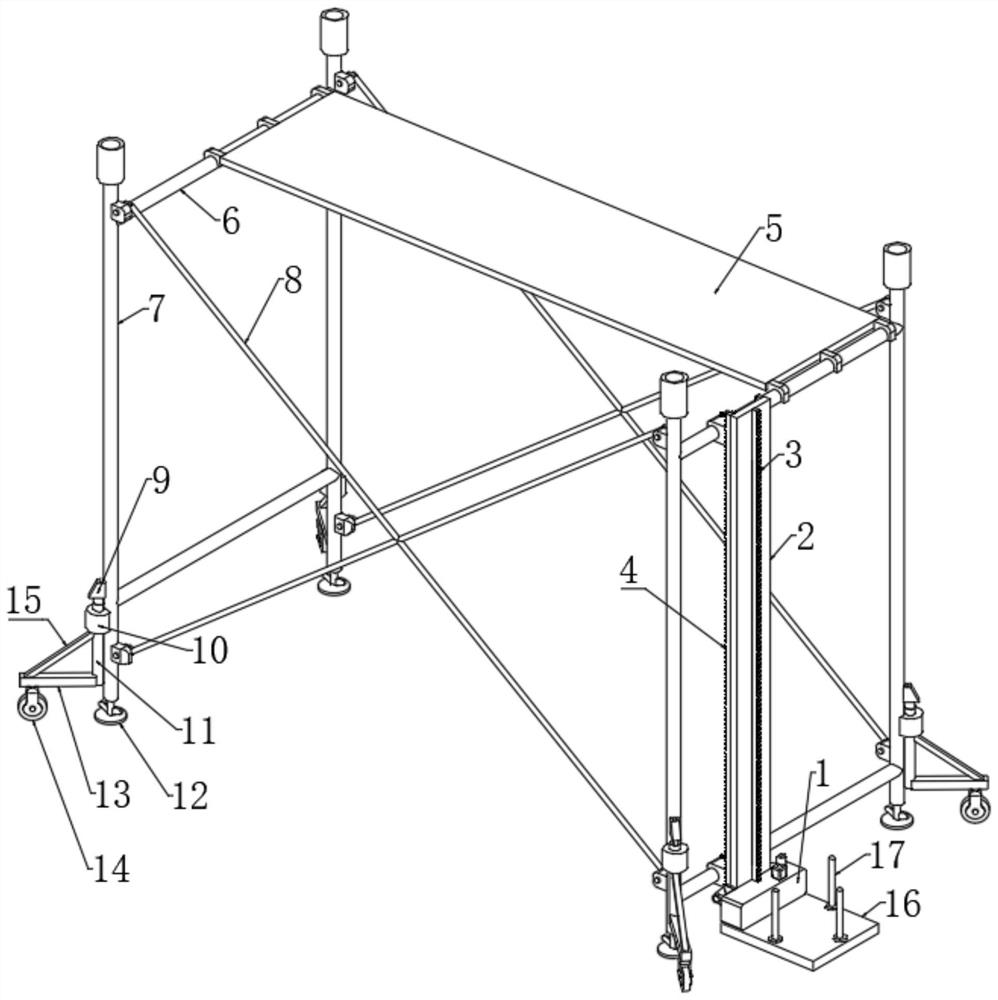

[0030] A climbing device for construction machinery, comprising four standpipes 7, four cross bars 6, two spacer frames 8 and vertically arranged support plates 2, the two spacer frames 8 are connected to the same vertical plane by bolts The pipe walls of the two vertical pipes 7 on the top are firmly connected, and the two ends of the two cross bars 6 are respectively fixedly connected with the pipe walls of the two vertical pipes 7 on the same vertical plane, and the two horizontal pipes on the same horizontal plane The rod 6 is connected with a construction platform 5 together, and the left end of the support plate 2 is fixedly connected with a fixed block 30 on the upper and lower sides. The upper end of block 32 is all fixedly connected with the side wall of support plate 2 by connecting block, and the side wall of fixed block 30 is fixedly connected with the bar wall of cross bar 6 by through hole, and the upper end of fixed block 30 is connected with fixed mechanism, and...

Embodiment 2

[0032] Embodiment 2: the difference based on Embodiment 1 is;

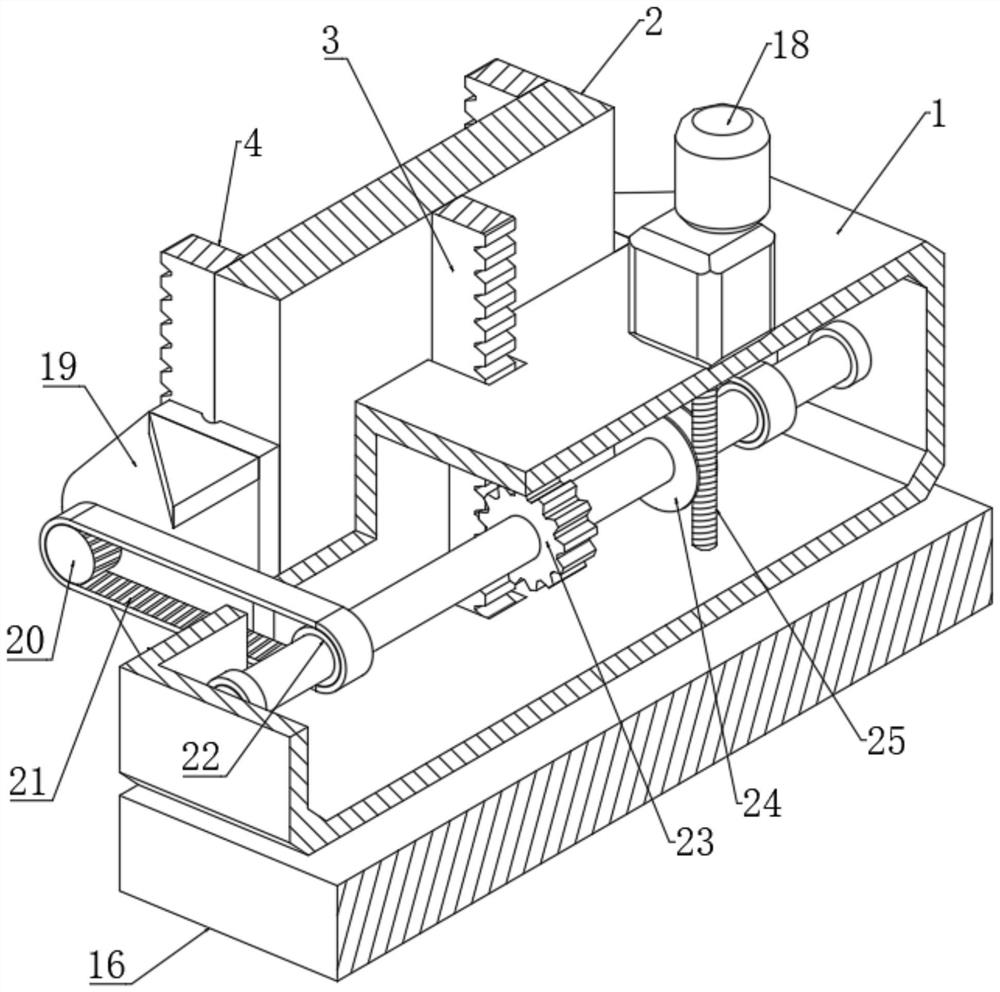

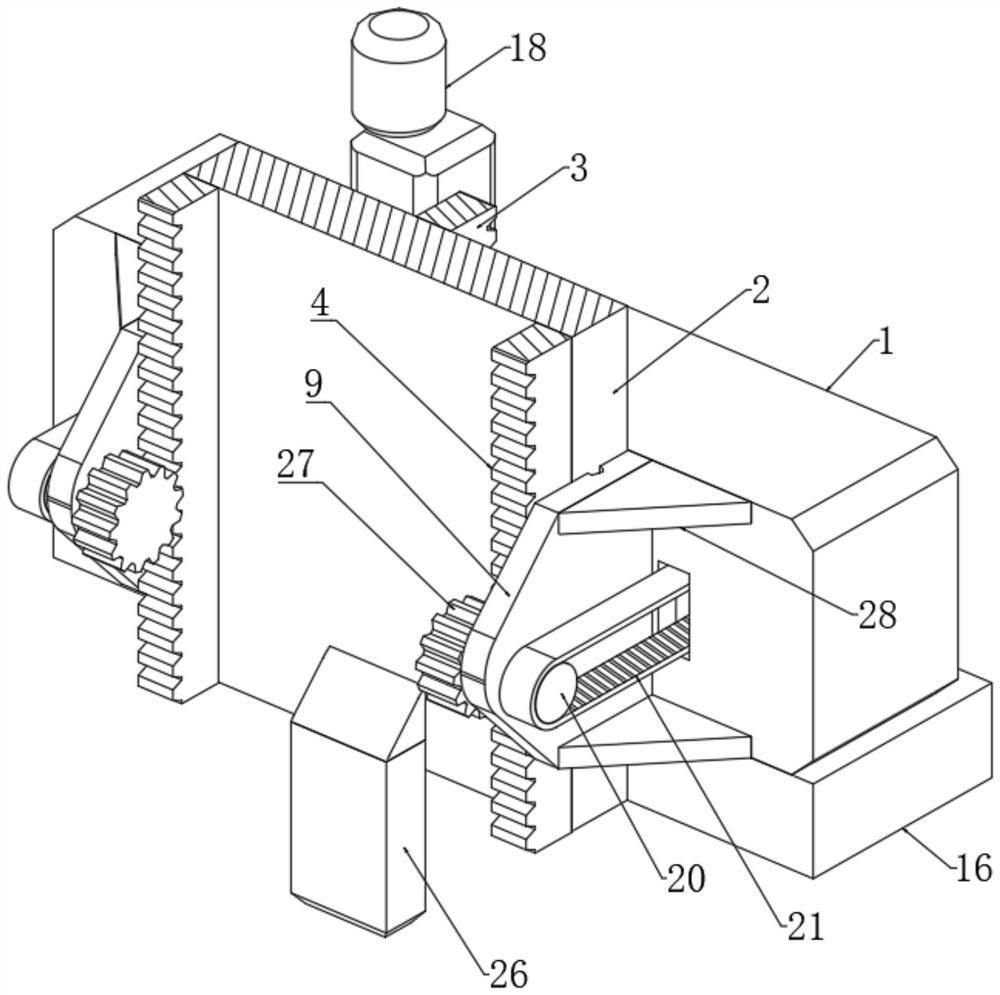

[0033] The climbing mechanism includes a rotating shaft connected in the box body 1 through the first rolling bearing. The shaft wall of the rotating shaft is fixedly connected with the first ring gear 23, the ring gear 23 meshes with the first rack 3, and the shaft wall of the rotating shaft is fixedly connected with a A turbine 24, one side of the turbine 24 is meshed with a worm 25, the upper end of the casing 1 is fixedly connected with a geared motor 18, the output shaft of the geared motor 18 runs through the side wall of the casing 1 and is fixedly connected with the upper end of the worm 25 coaxially, The opposite sides of the support plate 2 are slidingly connected with the mounting plate 19, and the right ends of the two mounting plates 19 are fixedly connected with the side wall of the box body 1, and the side wall of the support plate 2 away from the box body 1 is fixedly connected with two second The ...

Embodiment 3

[0035] Embodiment 3: the difference based on embodiment 1 is;

[0036] The fixing mechanism includes a rectangular rod 35 arranged in parallel on the top of the fixed block 30, the lower rod wall of the rectangular rod 35 is fixedly connected with the upper end of the fixed block 30 through two connecting rods, the rod wall of the rectangular rod 35 is slidably sleeved with a spring 34, One end of the spring 34 is fixedly connected with the rod wall of one of the connecting rods, the other end of the spring 34 is fixedly connected with a rectangular block, one side of the rectangular block is slidably connected with the rod wall of the rectangular rod 35 through a square hole, and one side of the rectangular block is fixed Connected with a triangular block 31, one side of the triangular block 31 is clamped with a positioning block 33, and the two ends of the positioning block 33 are fixedly connected with the two clamping blocks 32 on the fixed block 30 respectively, and the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com