Quartz plate production system and method capable of improving production efficiency

A production system and production efficiency technology, applied to flat products, household appliances, and other household appliances, can solve problems such as uneven hot air in the oven, complicated transfer process, and poor product quality, and achieve simplified transfer structure, hot air The effect of uniformity and improvement of surface flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

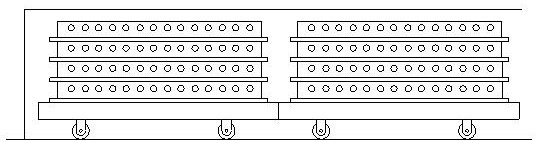

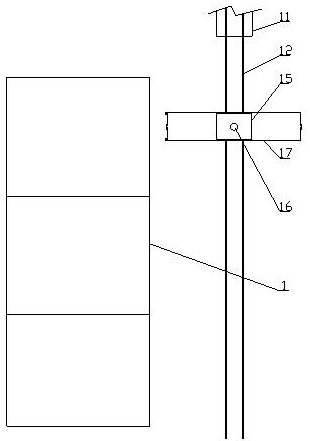

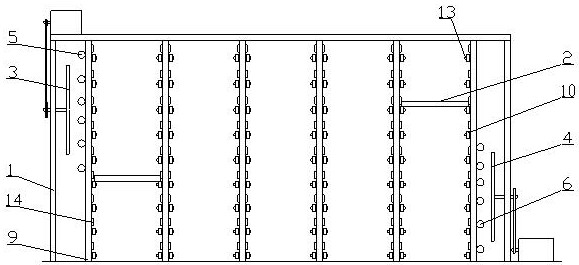

[0026] see Figure 2-6 , the embodiment of the present invention provides a quartz plate production system capable of improving production efficiency, the system includes a press molding device (using press molding), a curing device, a transfer platform 11 (conveyor belt, Send out the tray 2 (with a formed quartz plate on it), and the tray 2 can also be recovered) and the transfer manipulator between the transfer platform 11 and the curing device (for transfer tray 2), etc. Wherein, the discharge platform 11 is arranged along the front and rear directions. Among them, the baking device includes at least one baking oven 1 (rectangular box structure), and the oven 1 is provided with a lifting door that can be lifted and lowered, and a hot air structure and a plurality of trays 2 (for supporting quartz plates) are arranged inside. Wait. The aforementioned structure is basically the same as that of the existing quartz plate production system, the difference lies in:

[0027]The...

Embodiment 2

[0042] On the other hand, see Figure 2-6 , the embodiment of the present invention provides a quartz plate production method capable of improving production efficiency, which can be produced by using the system provided in embodiment 1. The method includes: rotating the bracket 17 to the left and right direction and docking with the transfer platform 11, manually pushing the tray 2 from the transfer platform 11 to a certain layer of support structure of the bracket 17, and placing the two fixed structures on both sides of the bracket 17 Lock to secure tray 2. The trolley 15 moves to the front of the baking rack along the left-right direction, and the bracket 17 is rotated to the front-to-back direction. By moving the trolley 15 left and right and the lifting arm 16 moving up and down, the bracket 17 has a tray 2 to be dried (the The support structure of the quartz plate on the top) is docked with a certain layer of the support structure of the baking rack, the fixed structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com