Driver safety airbag folding and shaping device and shaping process thereof

A technology for airbags and drivers, applied to other household appliances, household components, household appliances, etc., can solve the problems of airbag module cover tear lines, airbags cannot be loaded normally, etc., and achieve the effect of reducing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

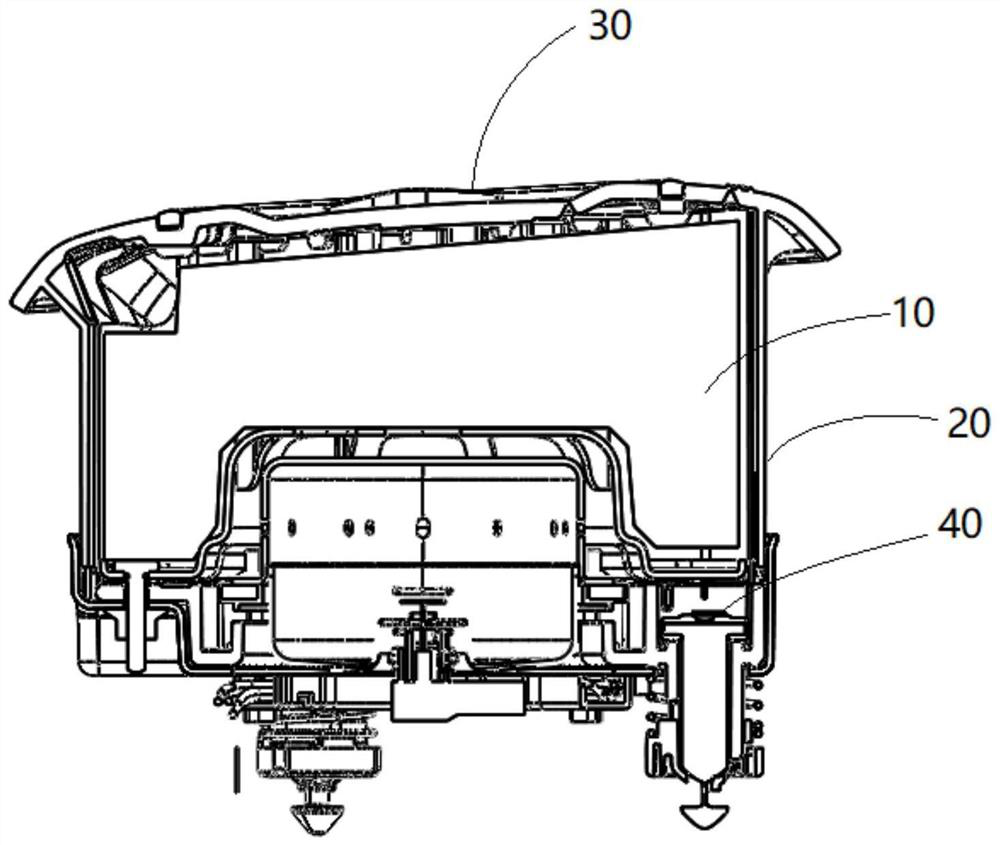

[0040] The driver's airbag folding and shaping equipment of the present invention includes at least one airbag shaping tool 100, an airbag press-fitting mechanism 200, a turnover vehicle 300, a heating device 400, a cooling device 500 and an airbag ejecting mechanism.

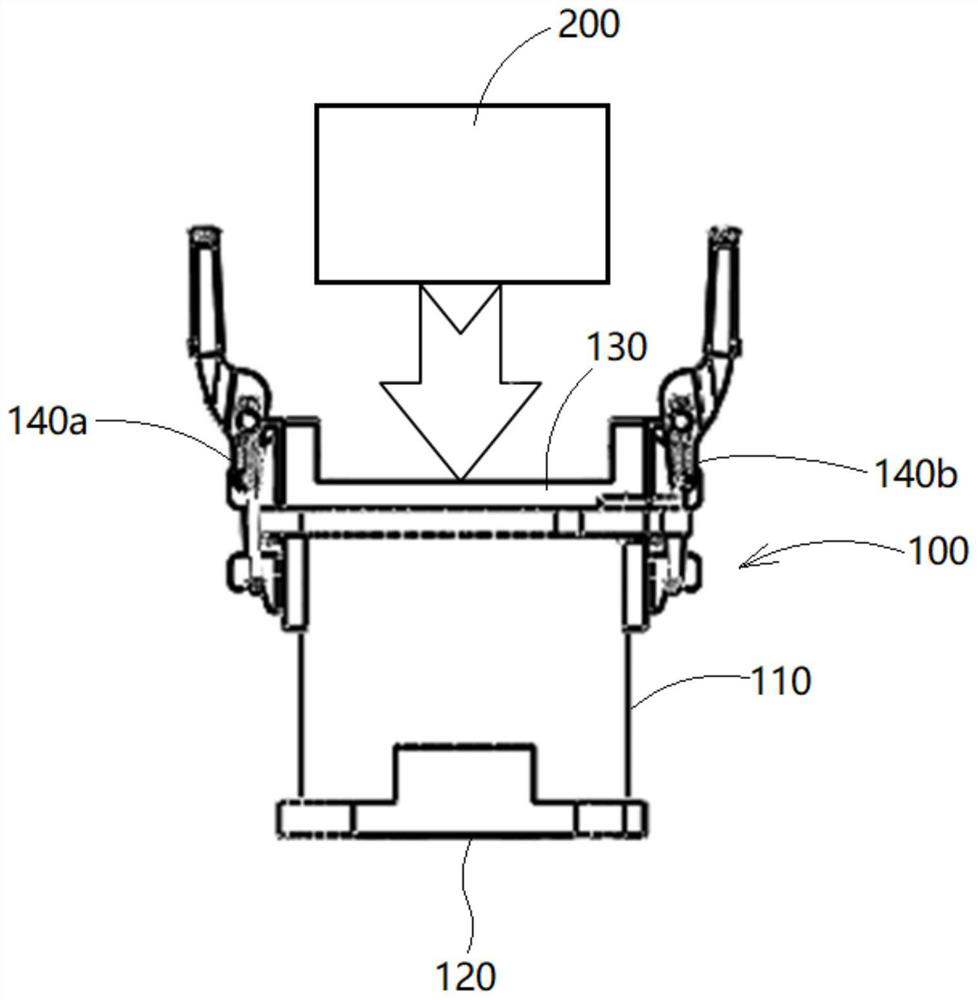

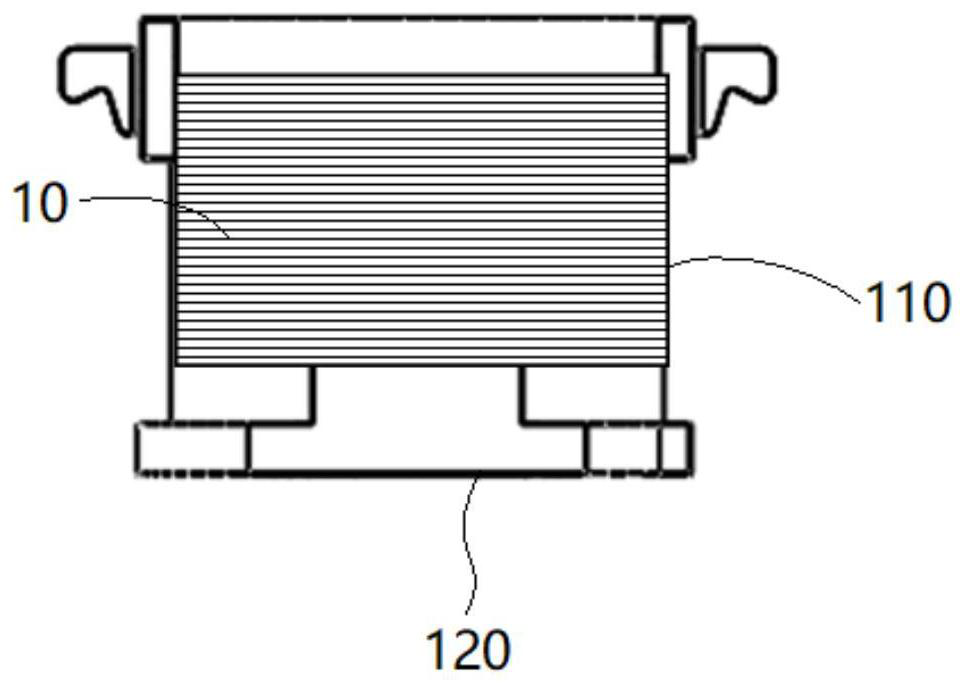

[0041] see figure 2 , the air bag shaping tool 100 is used to accommodate the folded air bag 10 . Specifically, the air bag shaping tool 100 includes an air bag shaping cylinder 110, a lower fixing plate 120 of the shaping tool, a pressing plate 130, and left and right locking pieces 140a, 140b. An air bag accommodating chamber is formed in the air bag shaping cylinder 110, and the air bag accommodating chamber is used to accommodate the folded air bag 10, such as image 3 sho...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap