Automatic indexing control method and device for fully-automatically-exchanged multidirectional swing head

An automatic indexing and control method technology, applied in the field of CNC machine tools, can solve the problems of tooth gap change, top teeth, and the inability to independently correct the angular gap gap change, etc., and achieve the effect of precise tooth gap compensation value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

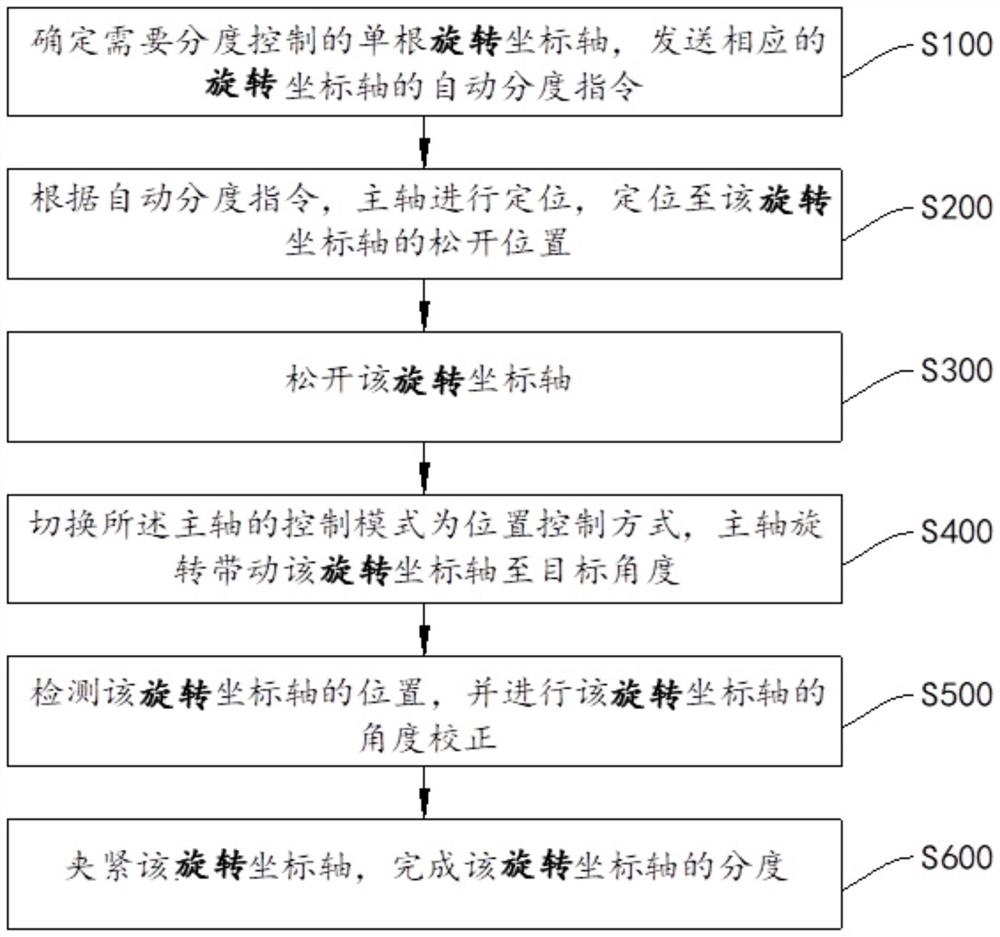

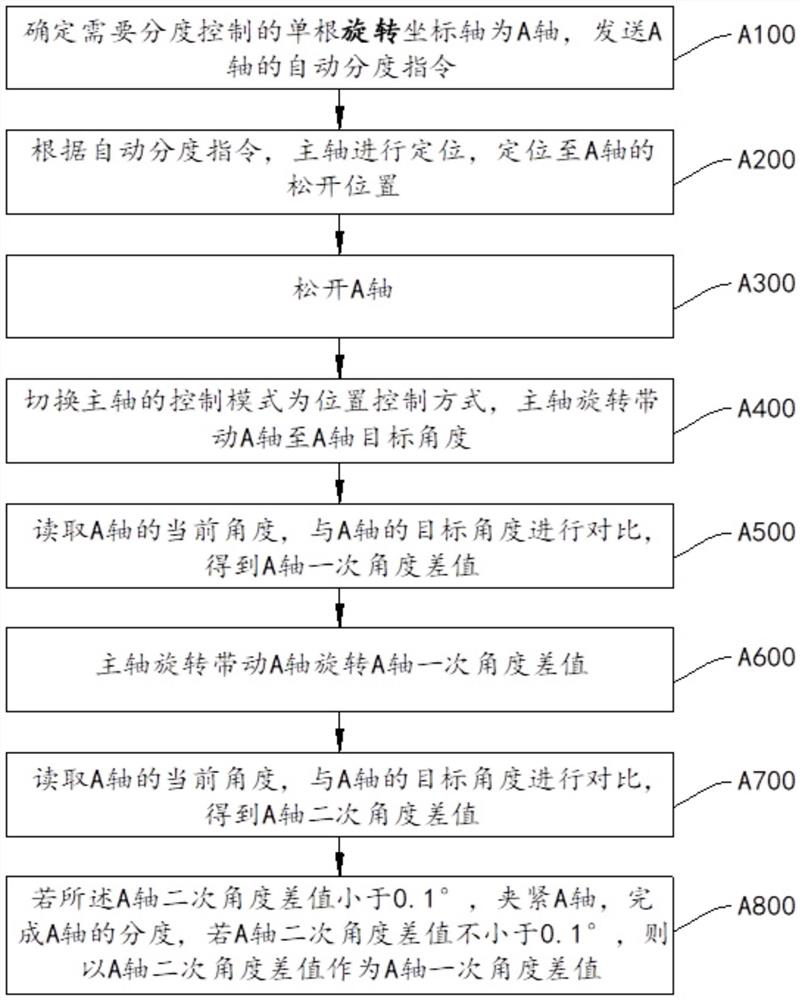

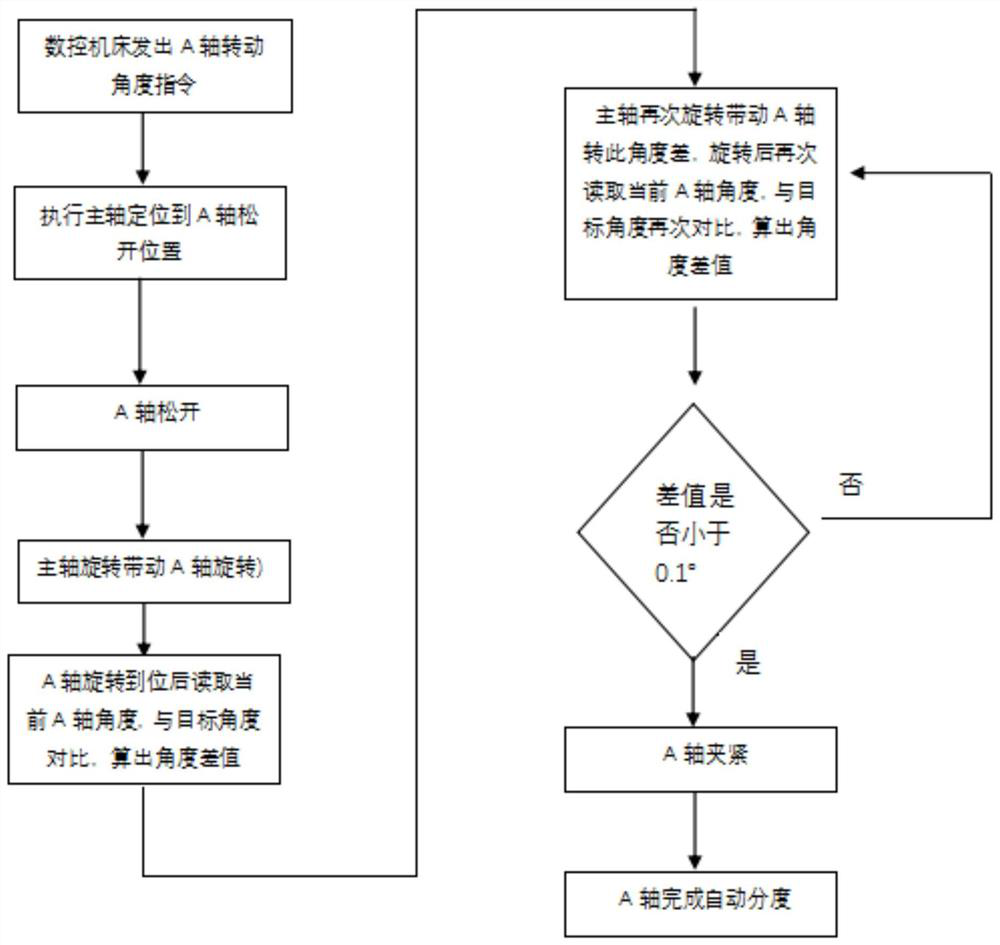

[0083] see figure 1 , the automatic indexing control method comprises the following steps:

[0084] S100) Determine the single rotating coordinate axis that needs indexing control, and send the corresponding automatic indexing command of the rotating coordinate axis. In this embodiment, the rotating coordinate axis is the A axis and the C axis, and at the same time in the automatic indexing control method One rotating coordinate axis is indexed in a single time, that is, the tooth gap of the A axis and the tooth gap of the C axis are separately corrected.

[0085] S200) According to the automatic indexing command, the spindle is positioned to the release position of the rotating coordinate axis. For the A axis and the C axis, the release points of the two axes are different and need to be calculated separately.

[0086] S300) Loosen the rotating coordinate axis through a hydraulic device.

[0087] S400) Switch the control mode of the spindle to the position control mode (the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com