Biomass particle forming device

A biomass granulation and molding device technology, which is used in the extrusion and granulation of raw materials, grain processing, solid separation, etc., can solve the problems of high equipment cost, high motor and tool requirements, and unfavorable use by small and medium-sized enterprises, and achieves equipment cost reduction. , The effect of improving product quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

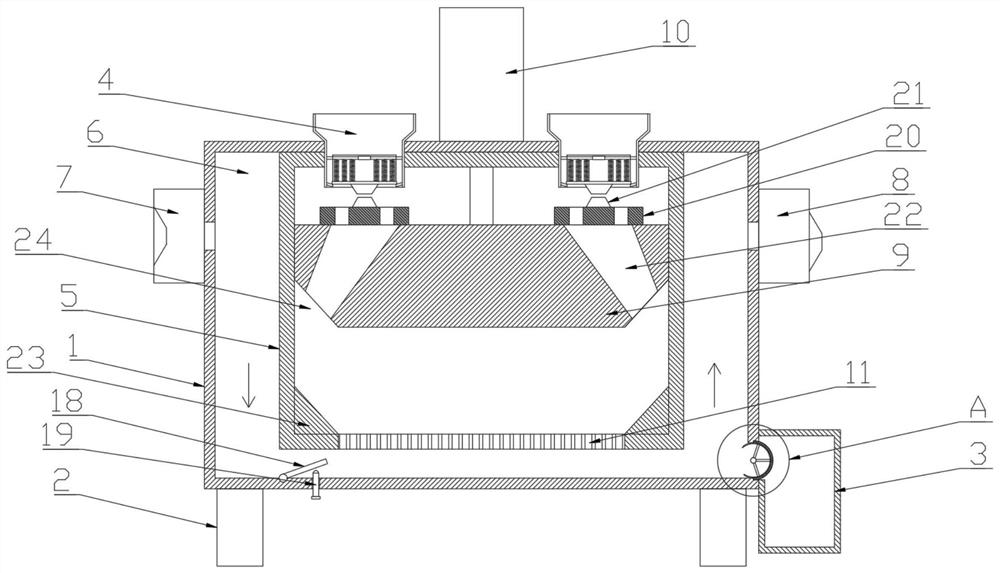

[0022] Please refer to the figure, in the embodiment of the present invention, a biomass particle molding device includes a casing 1, legs 2 and a collection box 3; a plurality of legs 2 are fixedly installed on the bottom of the casing 1, supporting the casing 1, collecting The box 3 is fixed on the bottom right end of the shell 1 to collect the formed biomass particles; an inner box 5 is fixedly installed in the shell 1, and the inner box 5 is fixed on the top of the shell 1 .

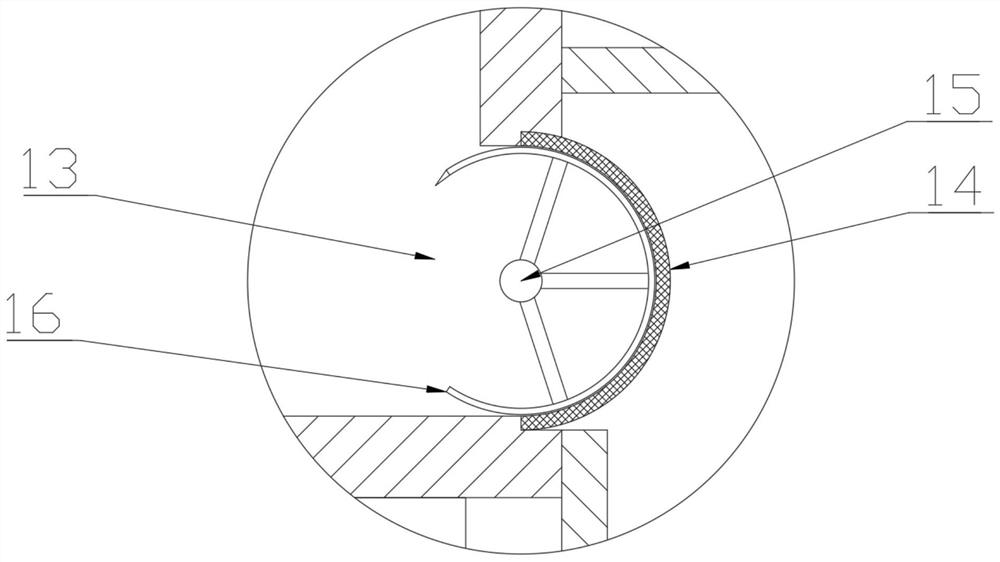

[0023] The inner box body 5 is provided with a pressing plate 9 moving in the vertical direction, the top center of the pressing plate 9 is fixedly connected to the output shaft of the vertical cylinder 10, and the pressing plate 9 is driven to move up and down by the cylinder 10; the inner box The bottom of the body 5 is embedded with an extrusion plate 11, and several extrusion holes are set on the extrusion plate 11, and the pressing plate 9 moves downward, and the raw material on the extrusion pla...

Embodiment 2

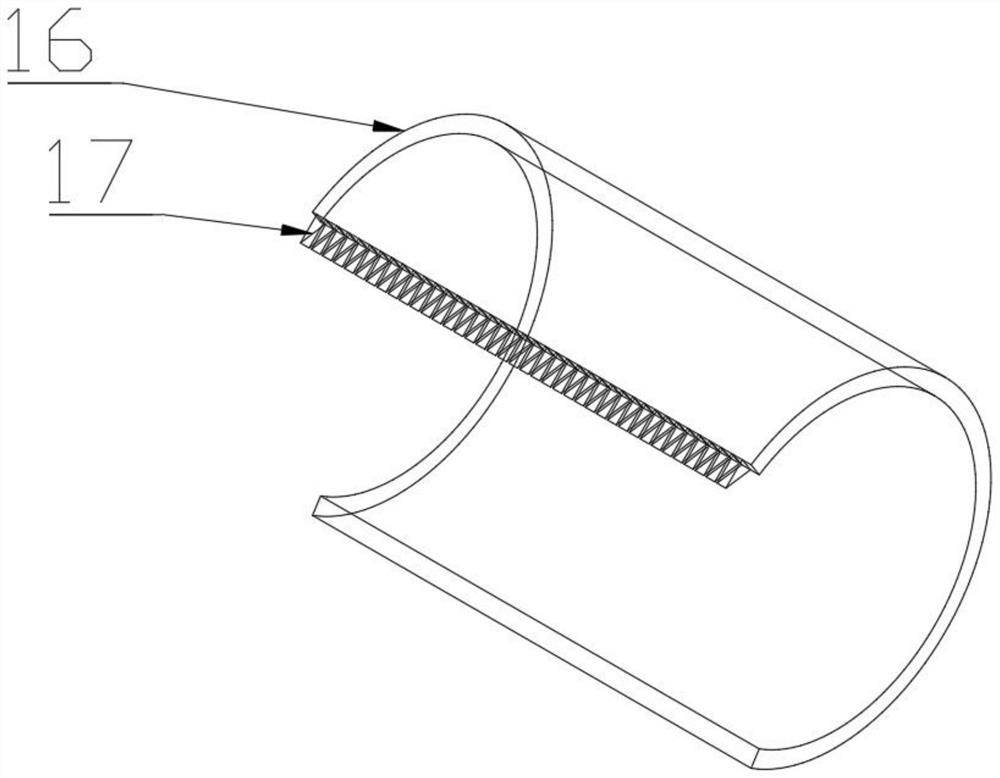

[0026] On the basis of Embodiment 1, at least two feed hoppers 4 are communicated on the top of the inner box body 5, and raw materials are loaded from the feed hoppers 4, and the feed hopper 4 includes a housing 41, and the bottom of the housing 41 A circle of support baffles 42 inclined downwards is fixed around the inner wall, and a horizontal movable sealing plate 43 moving in the vertical direction is arranged inside the housing 41. The edge of the movable sealing plate 43 is above the support baffle 42, When the movable sealing plate 43 falls on the support baffle plate 42, the bottom of the housing 41 is blocked to prevent the raw material from falling; Be fixed inside the housing 41 by the fixed rod 46, press the movable sealing plate 43 by the compression spring 45, keep the movable sealing plate 43 pressed on the support baffle plate 42; in order to prevent the raw material from falling on the movable sealing plate 43, The sealing plate 43 is fixed with a sealing cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com