A water treatment automatic pulse air lift sludge removal device

An automatic pulse and water treatment technology, applied in the direction of water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, special treatment goals, etc., to reduce over-flow resistance loss, improve air lift and sludge discharge efficiency, and realize instantaneous Effect of Pulse Gas Throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

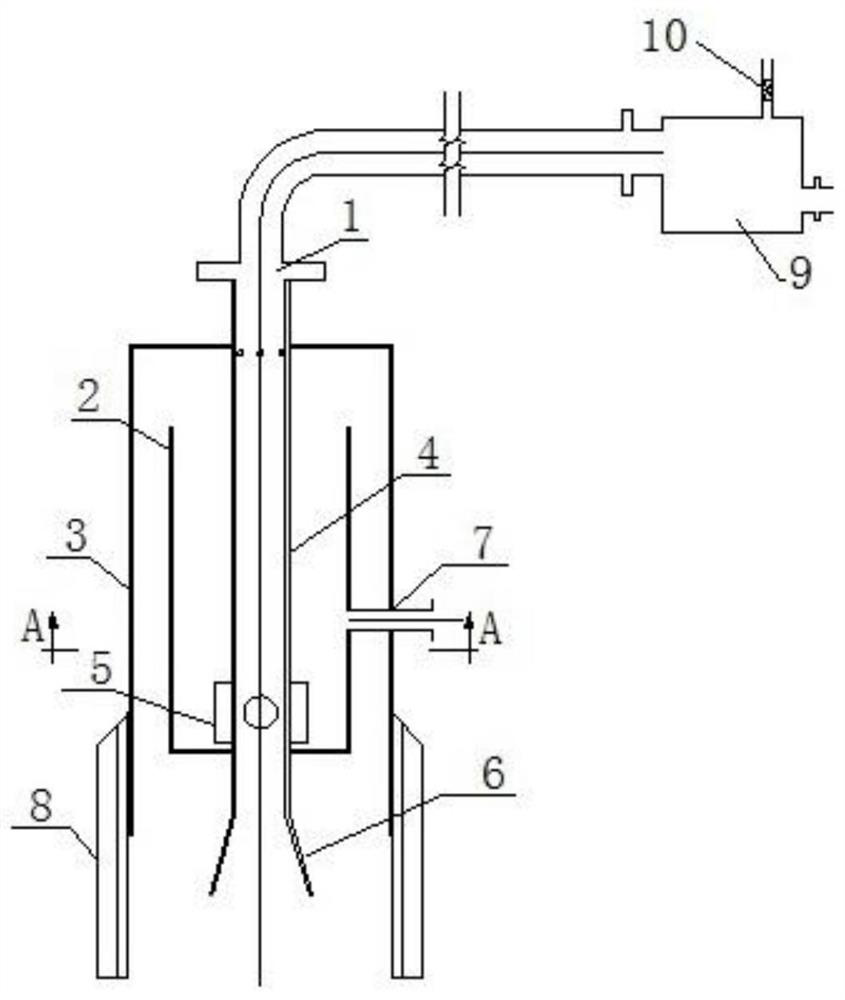

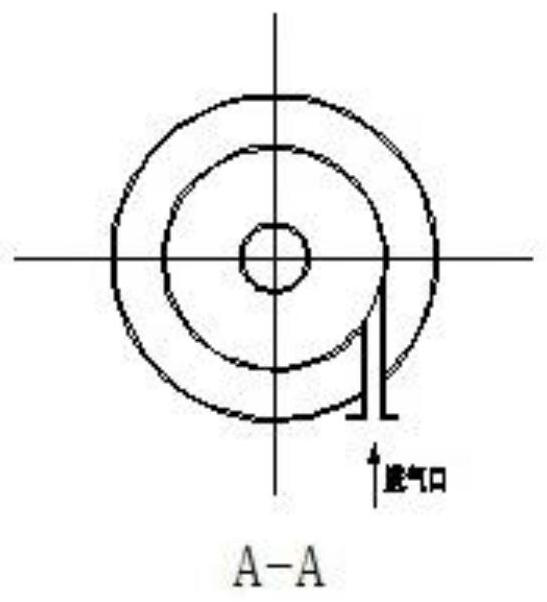

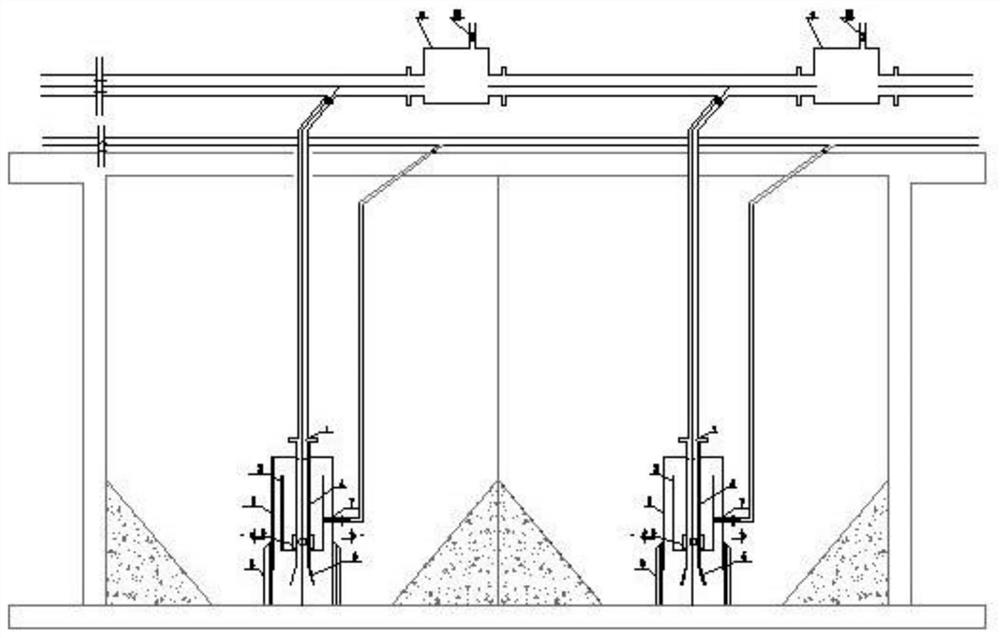

[0028] see Figure 1-2 , an embodiment provided by the present invention: a new type of automatic pulse air lift sludge discharge device, including a gas storage outer cavity 3, a gas storage inner cavity 2, a material inlet 6, a material outlet 1, a pulse tube 4, and a pulse component 5 , an air inlet pipe 7 and a fixing bracket 8, the air storage inner cavity 2 opens upward, the air storage outer cavity 3 opens downward, the air storage outer cavity 3 is inverted and arranged around the air storage inner cavity 2, and the air inlet pipe 7 Passing through the gas storage outer cavity 3 and connected with the air inlet on the gas storage inner cavity 2, the material inlet 6 is located under the gas storage inner cavity 2 and is connected with the lower end of the pulse tube 4, and the material outlet 1 is located in the gas storage cavity 2. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com