Tool-free mounting structure of fan connector

An installation structure and connector technology, which is applied to the components, connections, coupling devices, etc. of the connection device, can solve the problems of complicated installation process, unfavorable production efficiency, large plug-in force, etc., to ensure the relative positional relationship, application Convenience and the effect of reducing the insertion force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

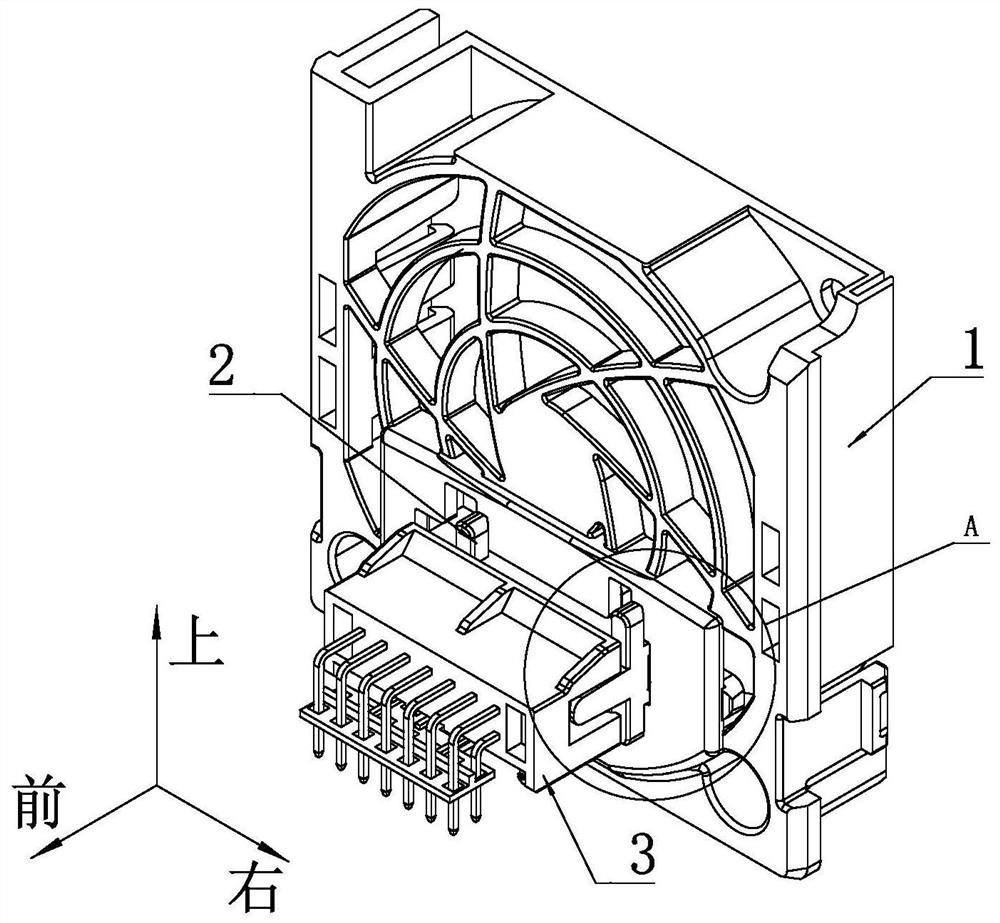

[0050] For the convenience of description, the coordinate system is defined as figure 1 , and the left-right direction is horizontal, the front-back direction is vertical, and the up-down direction is vertical.

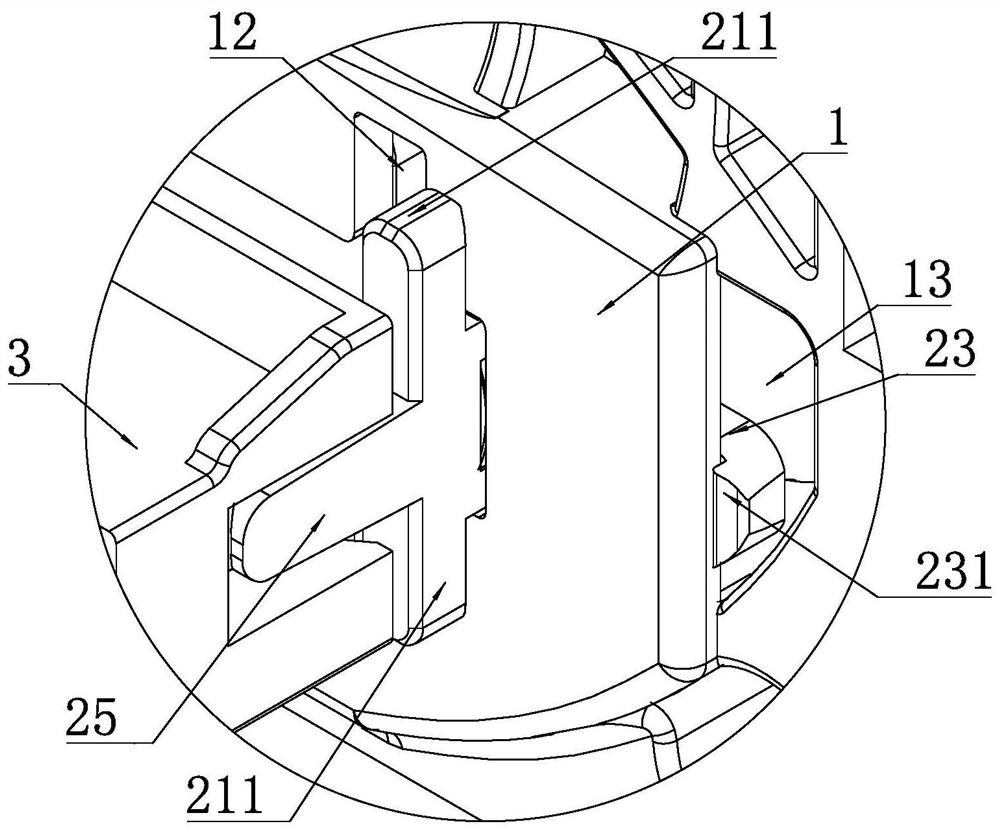

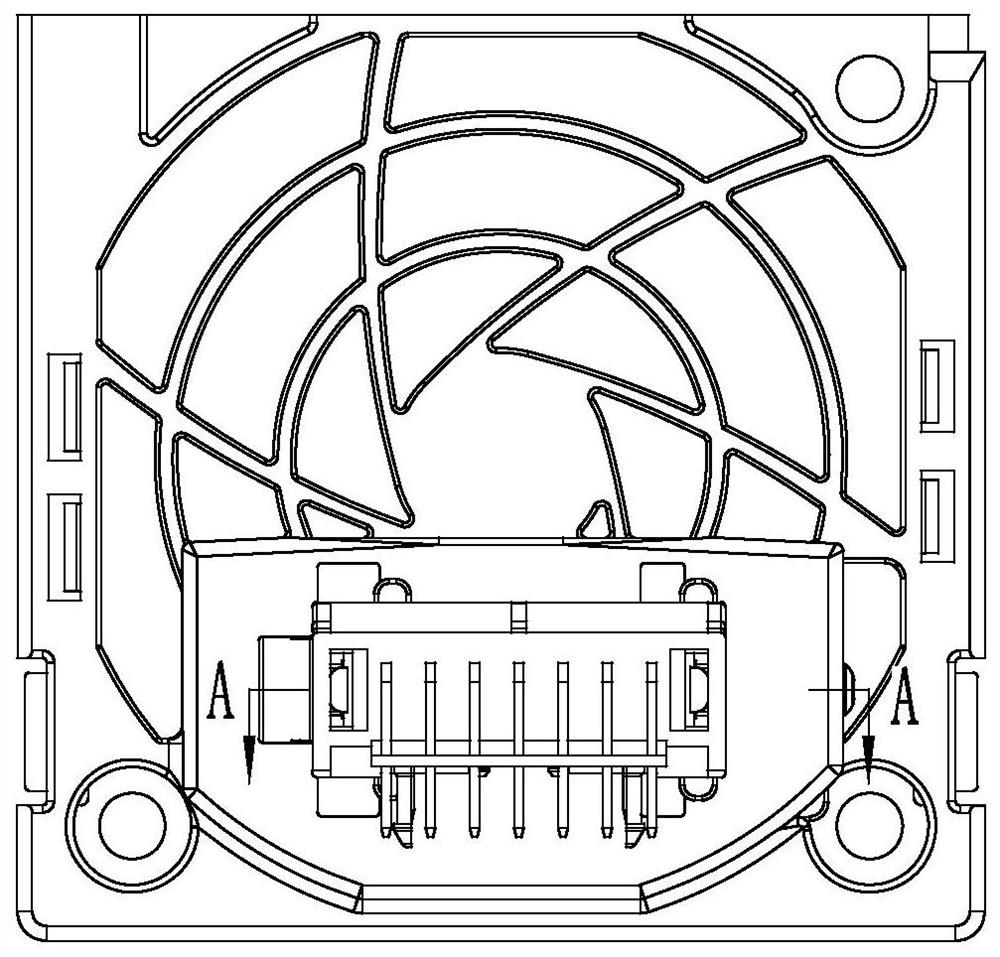

[0051] Such as figure 1 As shown, a fan connector tool-free installation structure includes a fan frame 1 for installing a fan and a fan connector arranged on the fan frame 1, and the fan connector includes a male 3 and a female 2, The male connector 3 is fixed on the main board (not shown in the figure), and the female connector 2 is fixed on the fan frame 1 .

[0052] Such as Figure 8 As shown, the female connector 2 of the fan connector includes a female connector body 21, and the front side of the female connector body 21 is provided with a plurality of insertion columns 26 extending longitudinally forward. As a specific embodiment, In this embodiment, a plurality of the insertion posts 26 are arranged in a matrix. A second installation hole extending longitu...

Embodiment 2

[0072] The limiting structure is a square limiting baffle 221 , and the upper side, lower side, left side and right side of the limiting baffle 221 respectively protrude from the outside of the female connector body 21 . All the other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com