A deep shale gas development method

A shale gas, deep-layer technology, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of operability, reduce injection displacement, and reduce the drag reduction effect of deep shale gas fracturing To achieve the effects of increasing the volume of reservoir stimulation, enhancing the shaping characteristics, improving the level of development technology and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In the following, the technical solutions in the present invention will be fully described in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the present invention All other embodiments obtained by those skilled in the art without creative efforts, all belong to the protection scope of the present invention.

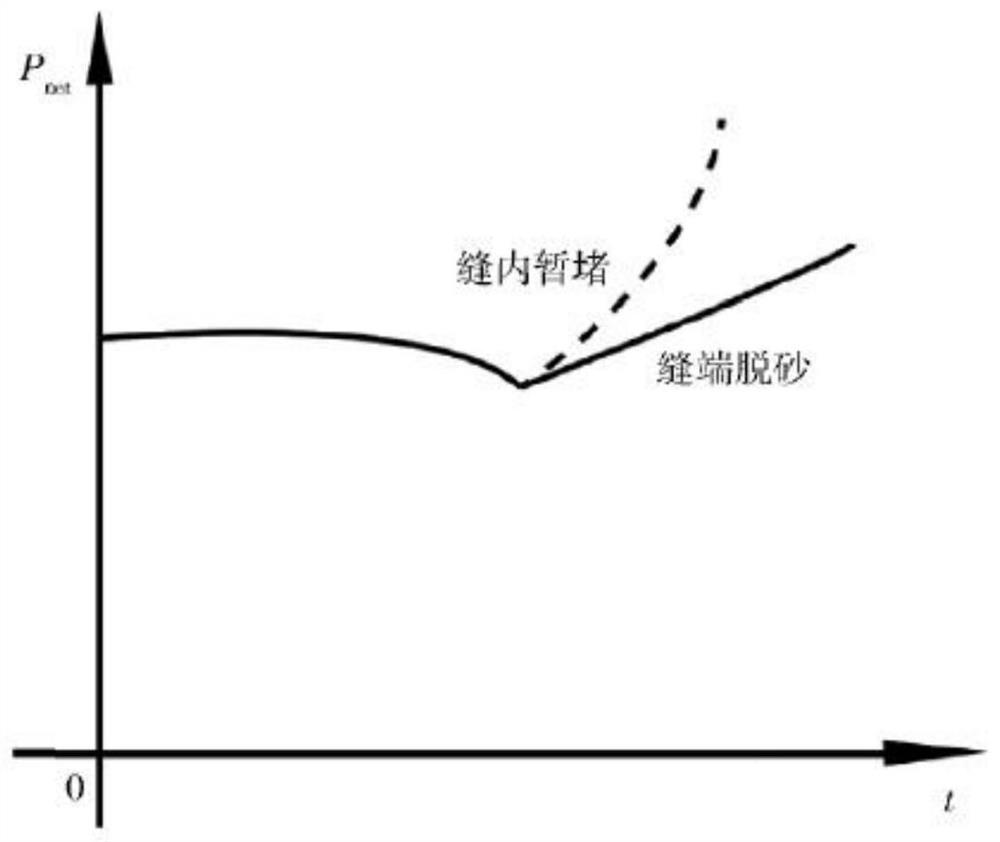

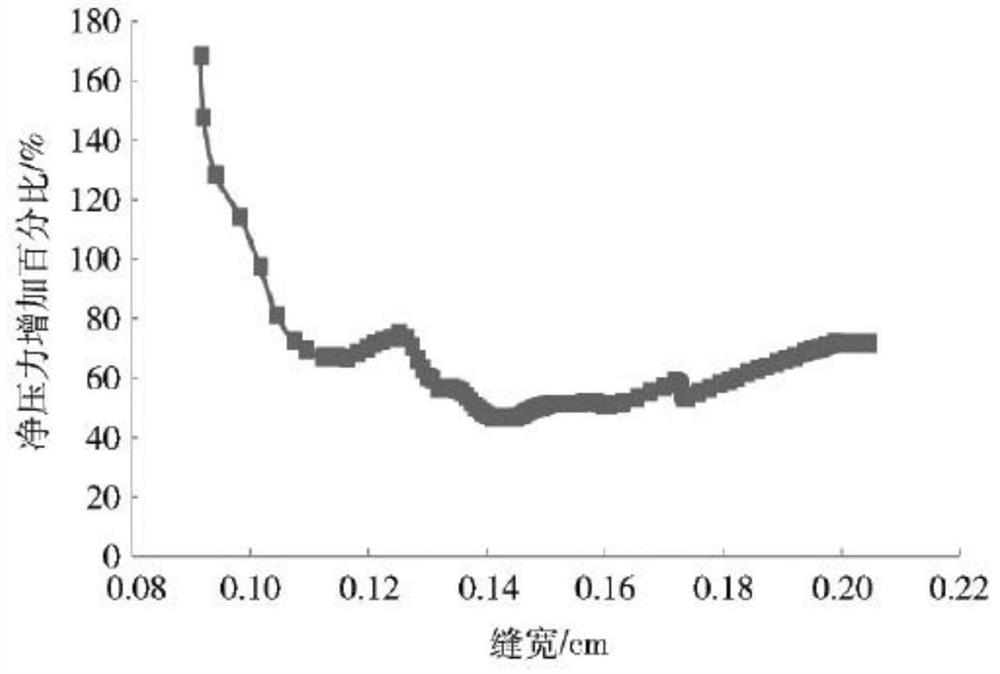

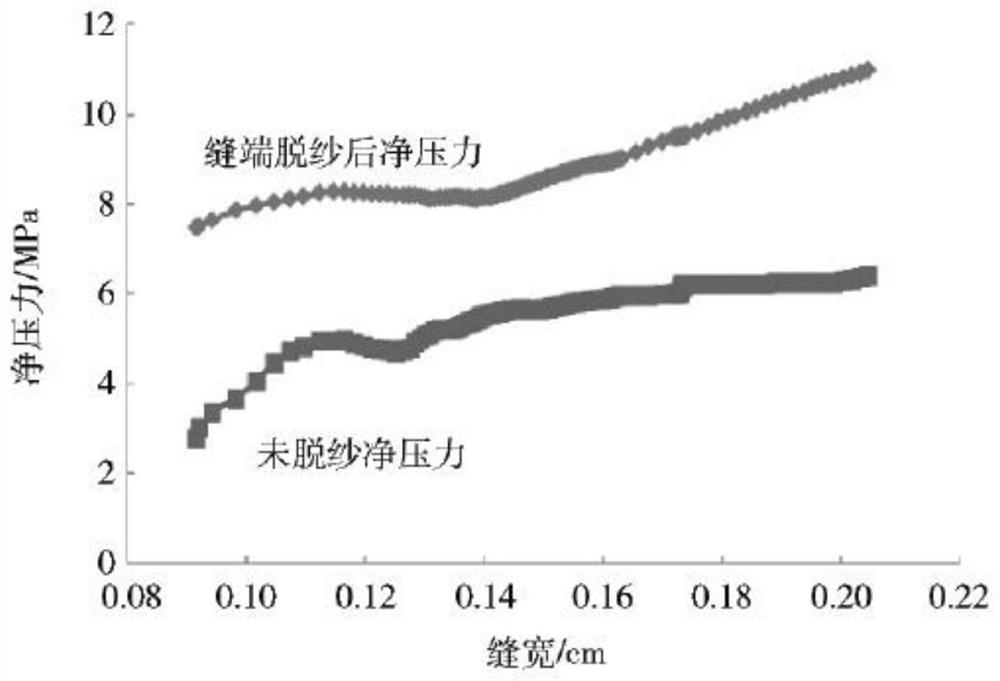

[0025] A method for developing deep oil shale gas, comprising the following steps: step (2), at first drilling three horizontal wells away from the water layer and fault zone; step (3), utilizing acid liquid to pretreat the wellbore at the perforation place; step (4), large-scale fracturing by using the horizontal section; in step (5), the sequence of injected fluid types is medium-viscosity slick water + low-viscosity acid + medium-viscosity glue, the medium-viscosity slick water, low-viscosity acid Both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com