Light transmission device punching equipment for vehicle-mounted microscope

A technology of punching equipment and light-passing device, which is applied in metal processing and other directions, can solve problems such as occurrence of errors and affecting the use of light-passing device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

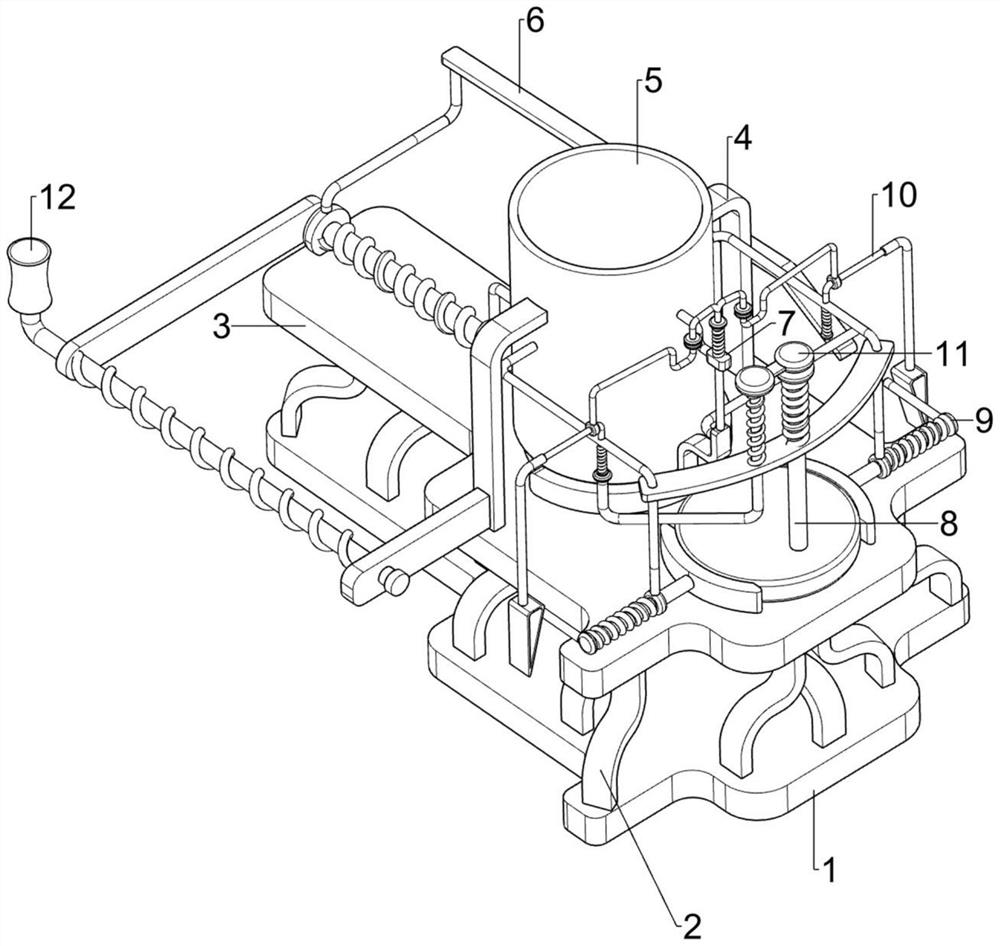

[0065]Car microscope lightner punching equipment, such asfigure 1 As shown, including the first support plate 1, the first support frame 2, the second support plate 3, the second support frame 4, the discharge frame 5, the push mechanism 6, the opening and joint mechanism 7, the punching mechanism 8 and the clip. Tight mechanism 9, the first support plate 1 is provided with a first support frame 2, and a second support plate 3 is provided at the top of the first support frame 2, and the second support plate 3 is provided with a second support frame 4 at the top of the second support plate 3. A discharge frame 5 is provided between the second support frames 4 on both sides, and a push mechanism 6 is provided in the lower left side of the discharge frame 5, and the upper right upper right side of the discharge frame 5 is provided with an opening and closing mechanism 7. A punching mechanism 8 is provided in the outer middle, and a clamping mechanism 9 is provided on the lower right si...

Embodiment 2

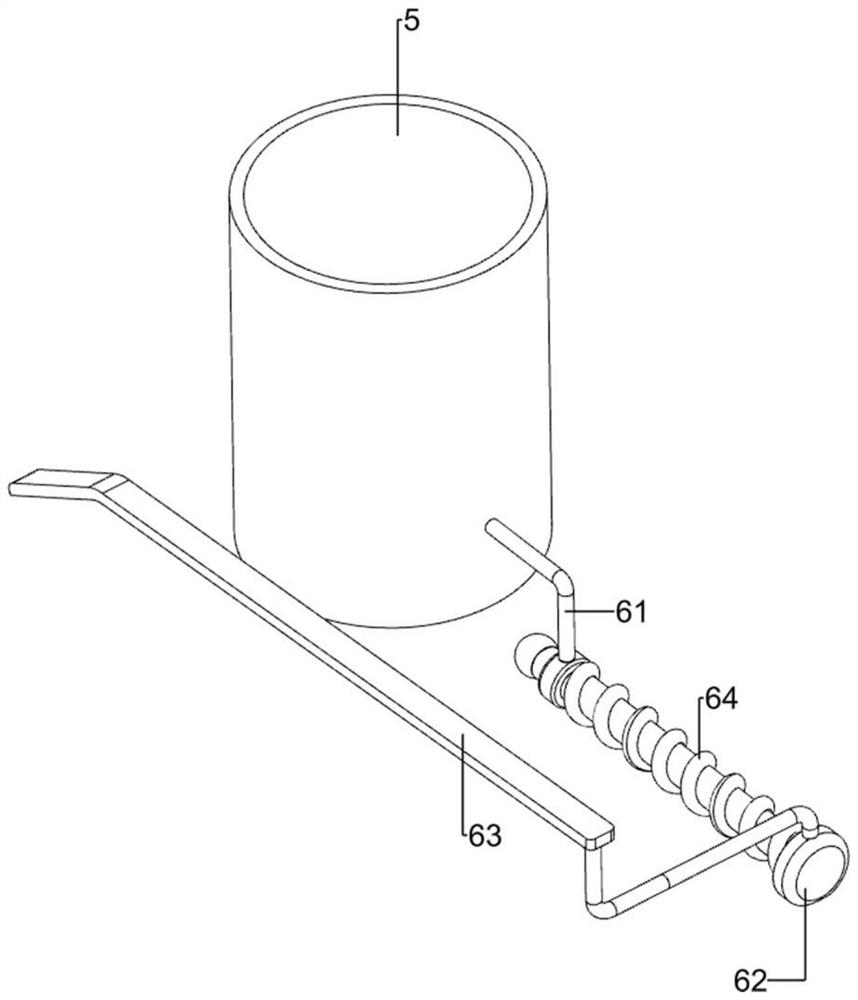

[0068]On the basis of Example 1, such asFigure 2- Figure 5 As shown, the pirate mechanism 6 includes a third support frame 61, a pincer 62, a first long block 63, and a first spring 64, and the outer upper left side of the discharge frame 5 is provided with a third support frame 61, the third support. The rack 61 is slid in the upper left side sliding pins 62, and the first long block 63 is provided on the left side of the pincedule 62, and the pincer 62 is surrounded by the first spring 64, the first spring 64 and the first respectively. The long block 63 and the third support frame 61 are connected.

[0069]In the discharge box 5, it is then manually pushed to the right movement, so that the pins 62 is moved to the right, and the first spring 64 is compressed, the pusher 62 is right Movement can introduce the lightner, realize the effect of the push, when people release, the first spring 64 resets the throttle 62 to move to the left, so that the first long block 63 is reset to the le...

Embodiment 3

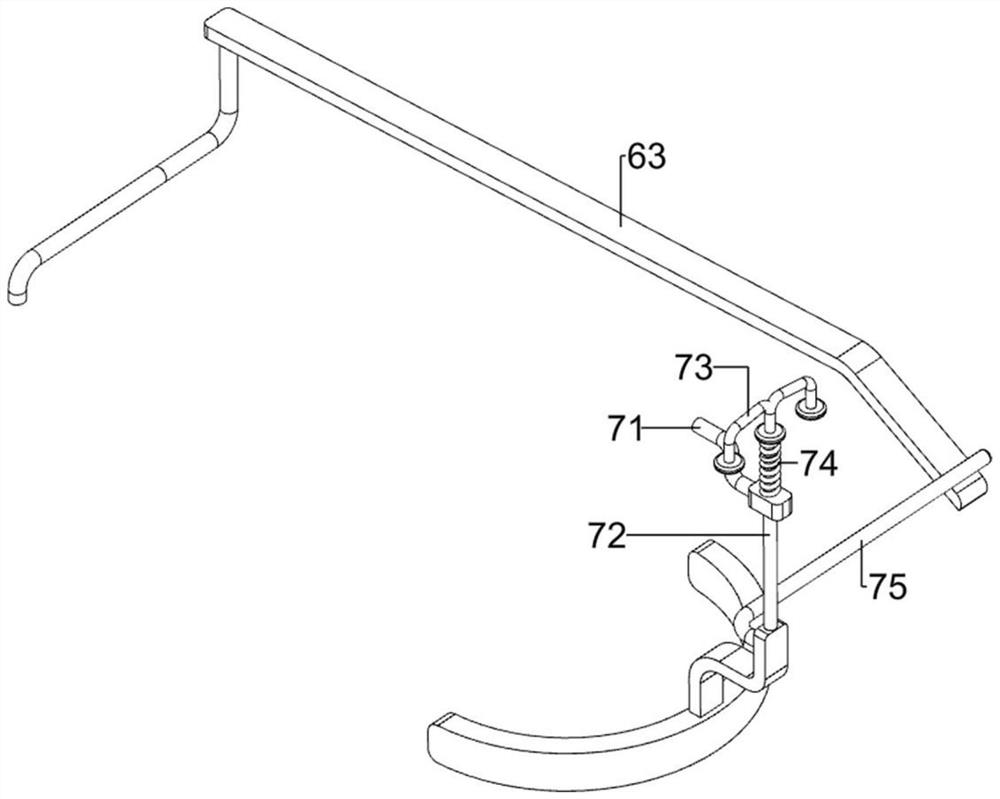

[0077]On the basis of Example 2, such asFigure 6 - Figure 8The first auxiliary mechanism 10 is further included, the first auxiliary mechanism 10 includes a first clip rod 101, a fifth spring 102, and a second circumferential rod 103, and the bottom side of the first round block 73 is sided. The second round block 103, the lower portion of the second round block 103 is provided with a first clip rod 101, and the first clip rod 101 is fitted with the second cylindrical rod 93, and the first counter rod 101 is slidoff. Connect, the inner lower portion of the first clip rod 101 is wound around the fifth spring 102, and the fifth spring 102 is connected to the first clip rod 101 and the first fixing lever 81, respectively.

[0078]When the first circumferential rod 73 moves upward, the first circumferential rod 73 drives the second round block rod 103 to move upward, the fifth spring 102 is compressed, so that the first club 101 is slid, the first club 101 is When the second cylindrical ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com