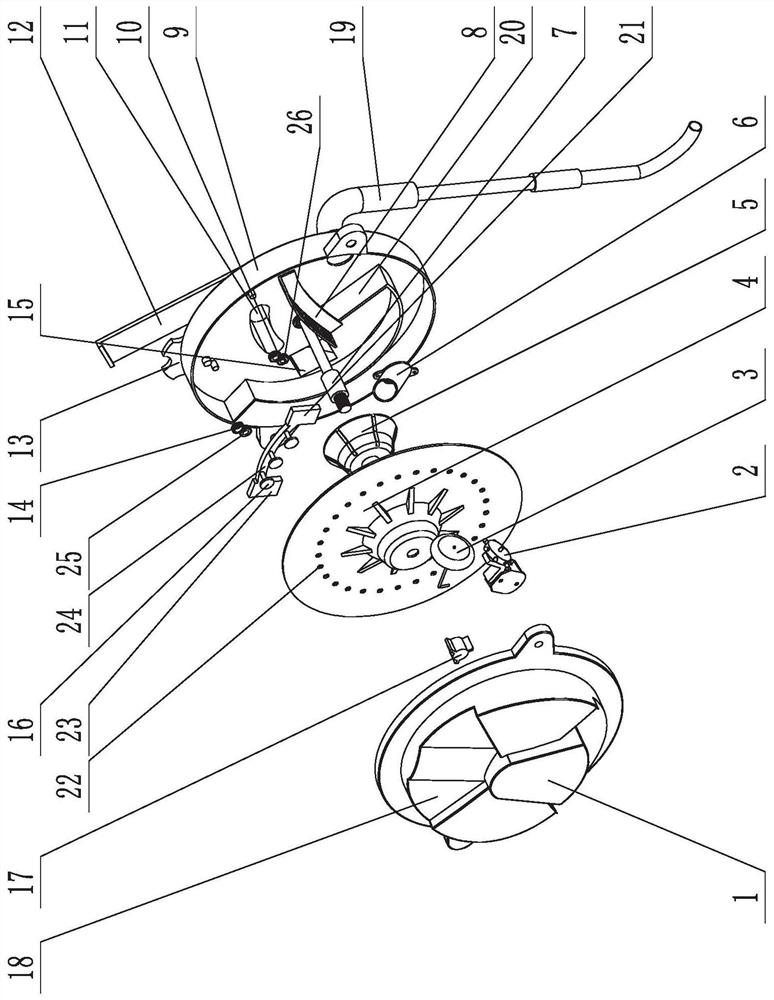

Positive-pressure pneumatic high-speed precision seed-metering device

A kind of seed metering device and precision technology, applied in the direction of sowing seeder, seeder parts, etc., can solve the problems of low seeding rate and void rate, uniformity of seeding, etc., to achieve good seeding uniformity, novel structure, Less power consumption for work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

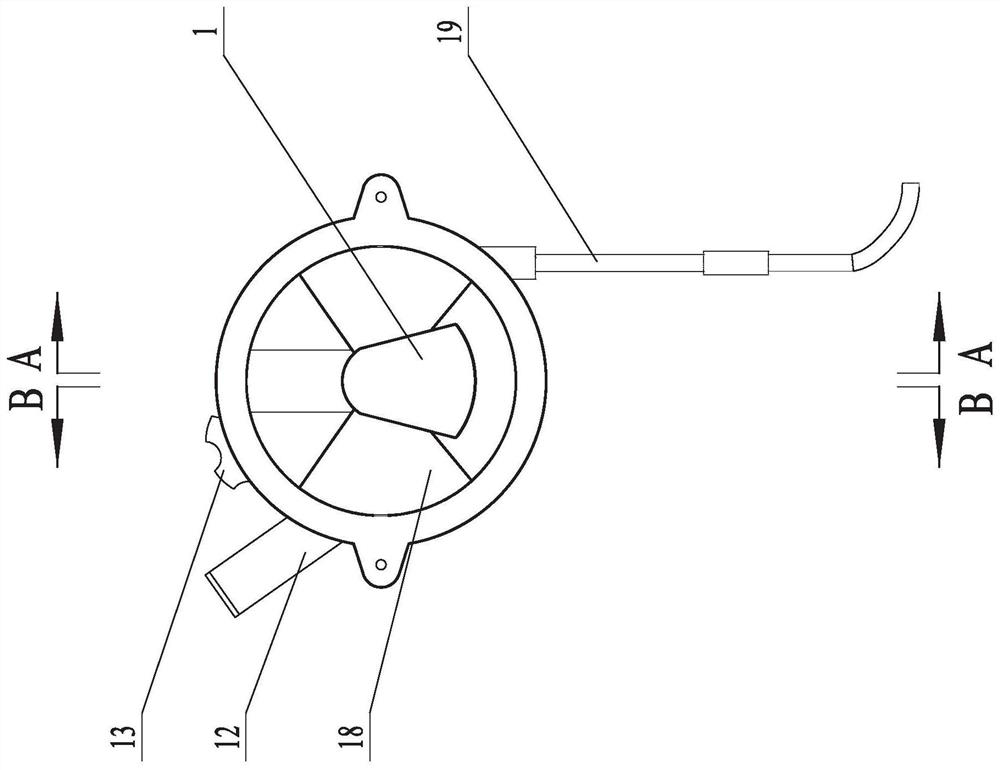

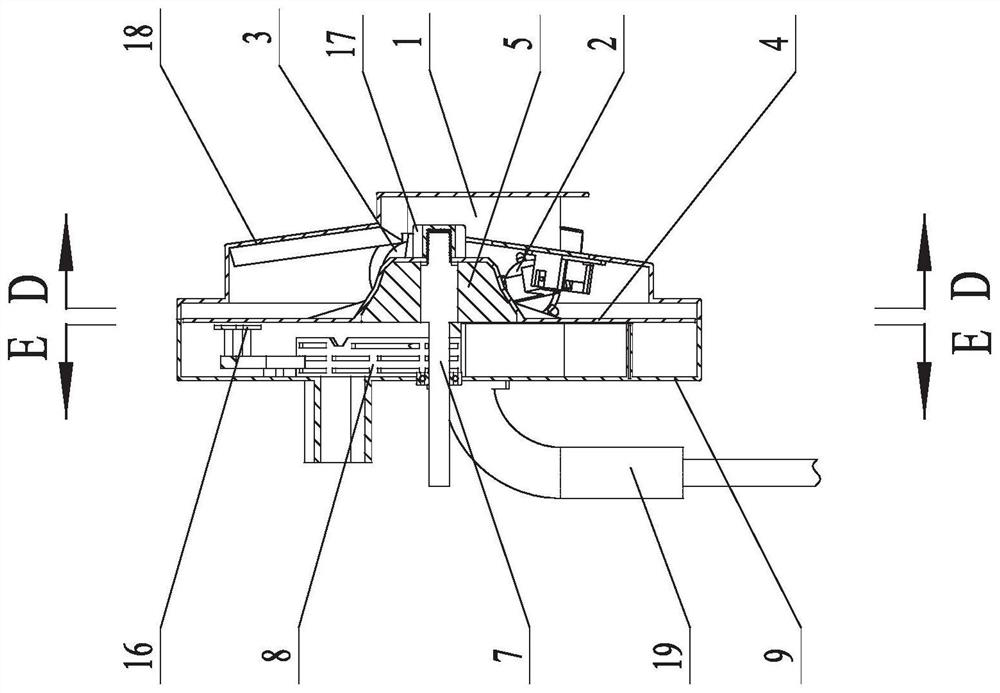

[0018] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A positive pressure pneumatic high-speed precision metering device, a drive shaft 7 is rotatably mated and mounted on the center of the end wall of the right housing 9, and the drive shaft 7 is located inside the cavity of the right housing 9 Through the drive seat 5 and the locking nut 17, the axially, circumferentially and radially positioned fixed filling and discharging discs 4, on the same turning radius part of the filling and discharging seed discs 4, a plurality of filling and discharging discs are evenly distributed along the circumferential direction. Seed through holes 22, a plurality of stirring grooves 27 with the same number as a plurality of filling and discharging seed through holes 22 are evenly distributed along the circumferential direction, and are arranged on the filling and discharging seed tray 4 corresponding to the filling and dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com