Novel pipe rod storage and maintenance system for drilling/workover operation

A maintenance system, pipe and pipe technology, applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems that do not meet the requirements of green well site construction, occupy a large area, and waste oil and wastewater cannot be fully collected and discharged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Below in conjunction with accompanying drawing and specific embodiment, general scheme of the present invention is described in further detail:

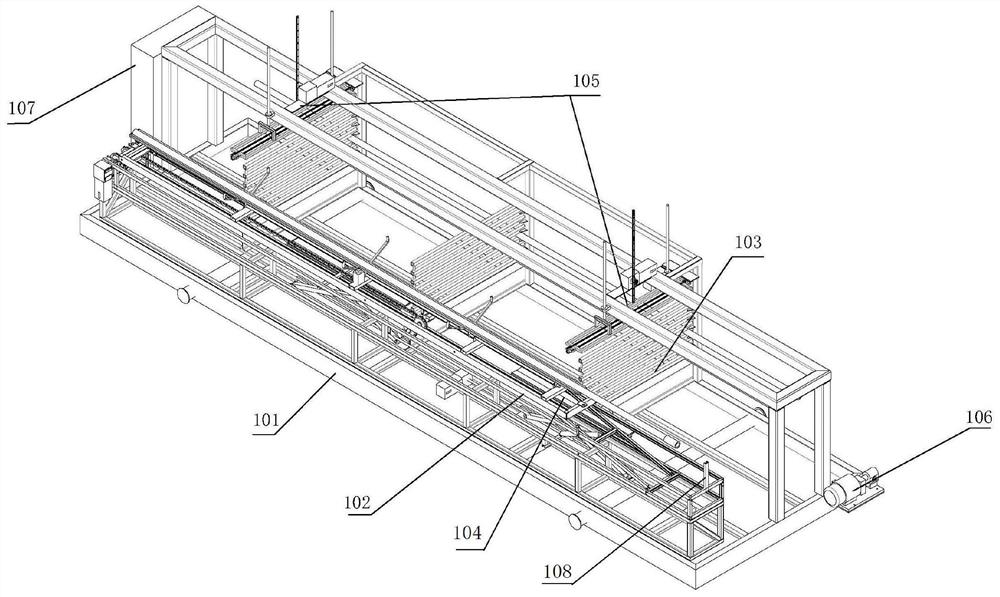

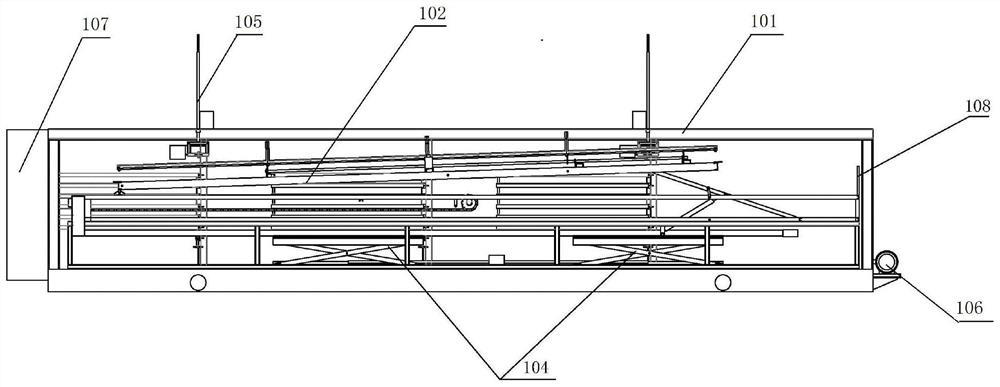

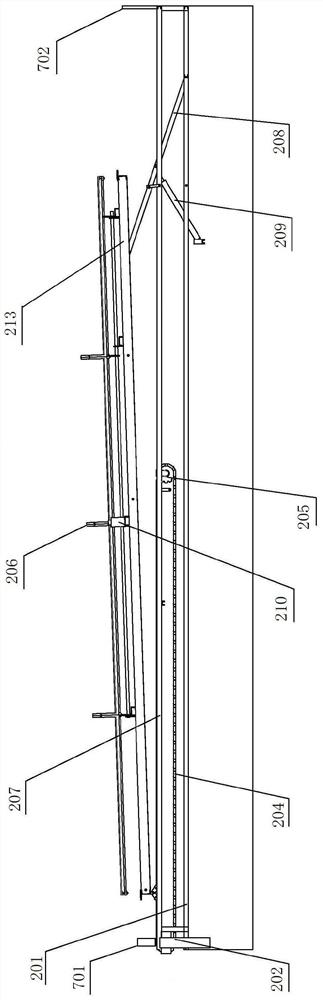

[0058] see figure 1 , 2 , the present invention includes a main pipe box 101, a pipe rod conveying system 102, a layered bracket structure 103, a pipe rod receiving system 104, a pipe rod placement system 105, an automatic sewage system 106, a control system 107 and a pipe rod length measurement system 108 . The pipe and rod conveying system 102, the layered bracket structure 103 and the pipe and rod receiving system 104 are all arranged in the main pipe box 101, and the pipe and rod receiving system 104 is arranged between the pipe and rod conveying system 102 and the layered bracket structure 103. The rod placement system 105 is arranged on the upper part of the main pipe box 101 and above the layered bracket structure 103 .

[0059] The main pipe box 101 is welded by section steel, steel grid is laid on the bottom, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com