Tension self-adjusting type combined joint for full-tension crossed cable truss structure

A truss structure, combined node technology, applied in truss structure, truss beam, building structure and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

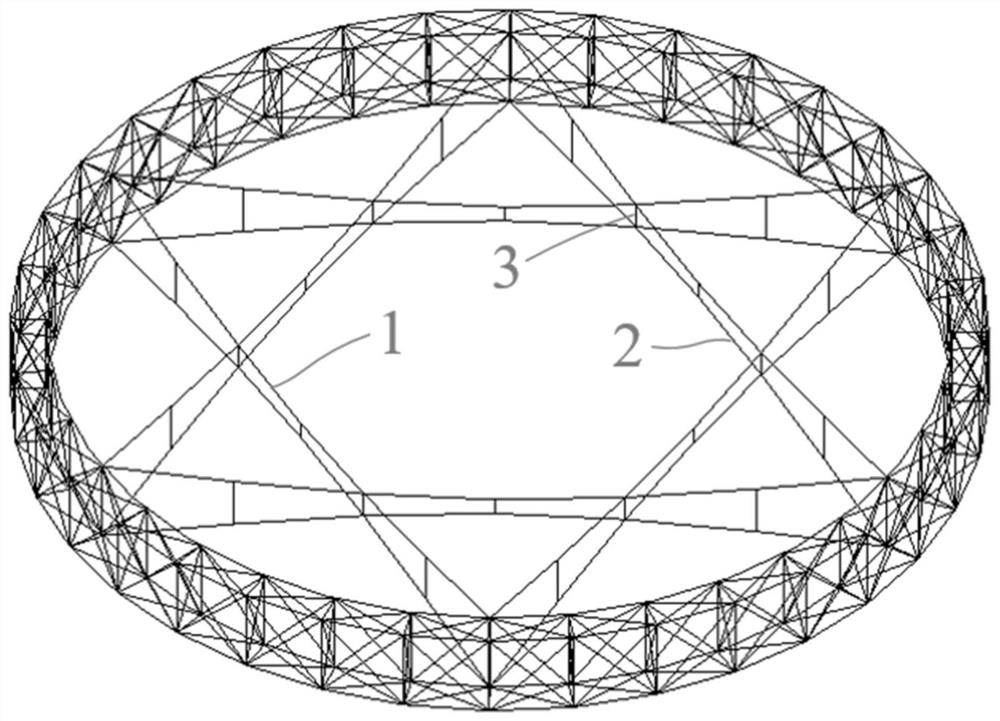

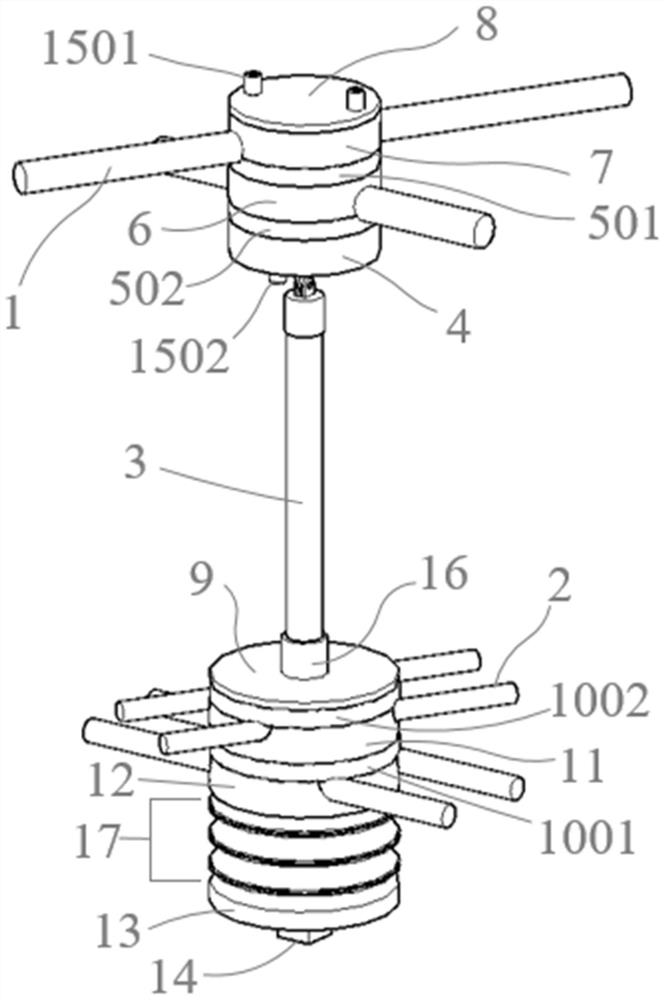

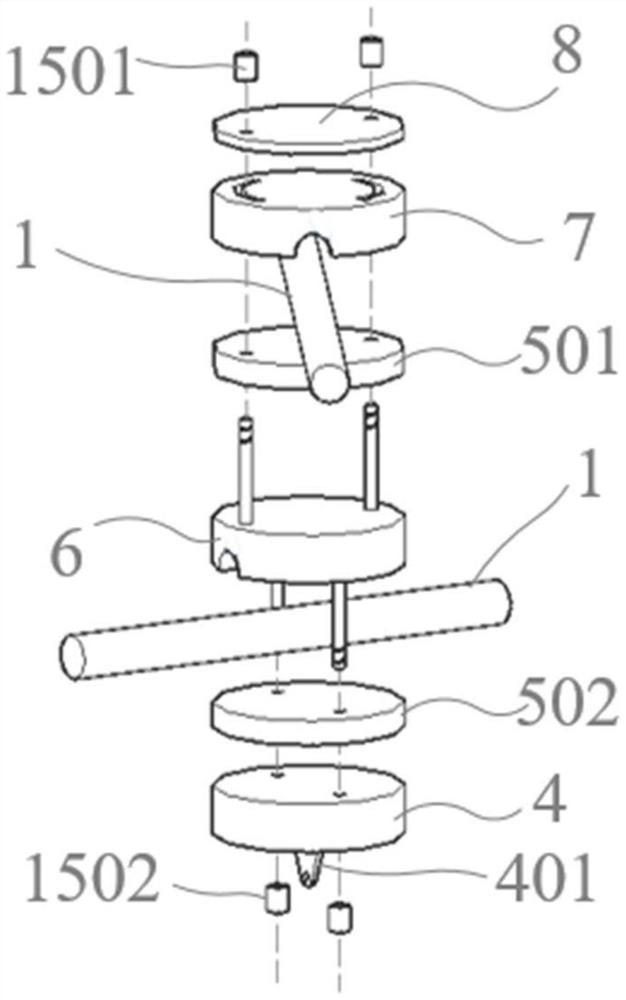

[0023] to solve figure 1 According to the design and use of the structural system shown, the embodiment of the present invention provides a combined node of a fully tensioned cross-cable truss structure, such as figure 2 As shown, the upper node is composed of main cable groove 6, secondary cable groove 7, rubber block A501, rubber block B502, base 4, cover plate 8, nut A1501 and nut B1502; the lower node is composed of upper cable groove 11, lower cable Groove 12, gasket 9, rubber layer A1001, rubber layer B1002, disc spring 17, anchor plate 13, anchor clamp 14 and nut C16.

[0024] Such as image 3 As shown, the lower surface of the main cable groove 6 has a strip-shaped groove that can be embedded in the cable in one direction of the upper string cable 1; the lower surface of the secondary cable groove 7 has a strip-shaped groove that can be embedded in the upper string The cable in the other direction in the cable 1; the upper surface and the lower surface of the main c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com