One-time waste discharge punching forming method

A waste material and outer frame technology, applied in metal processing, etc., can solve problems such as increasing manufacturing costs and affecting work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

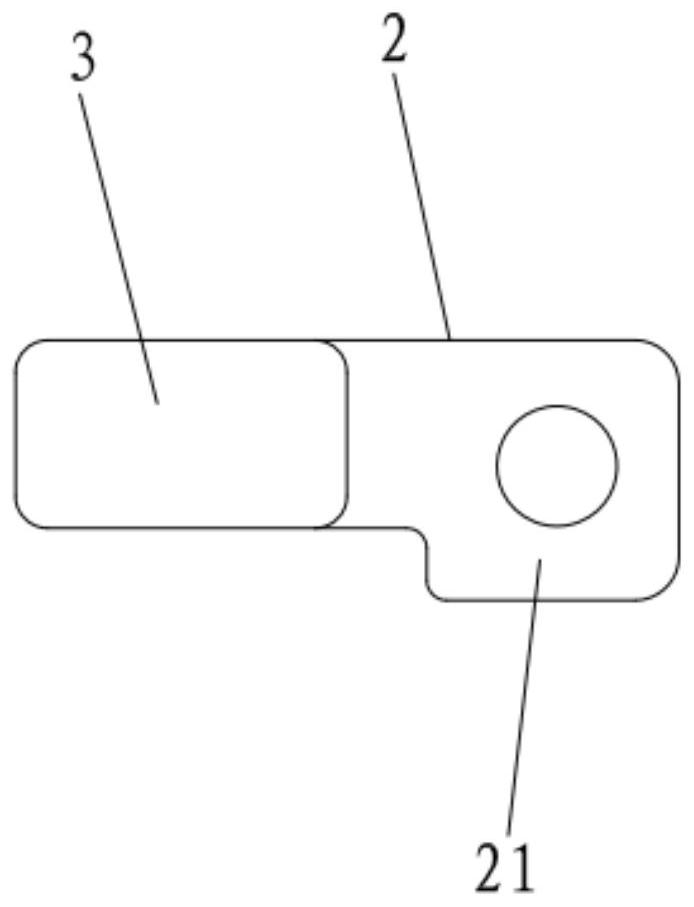

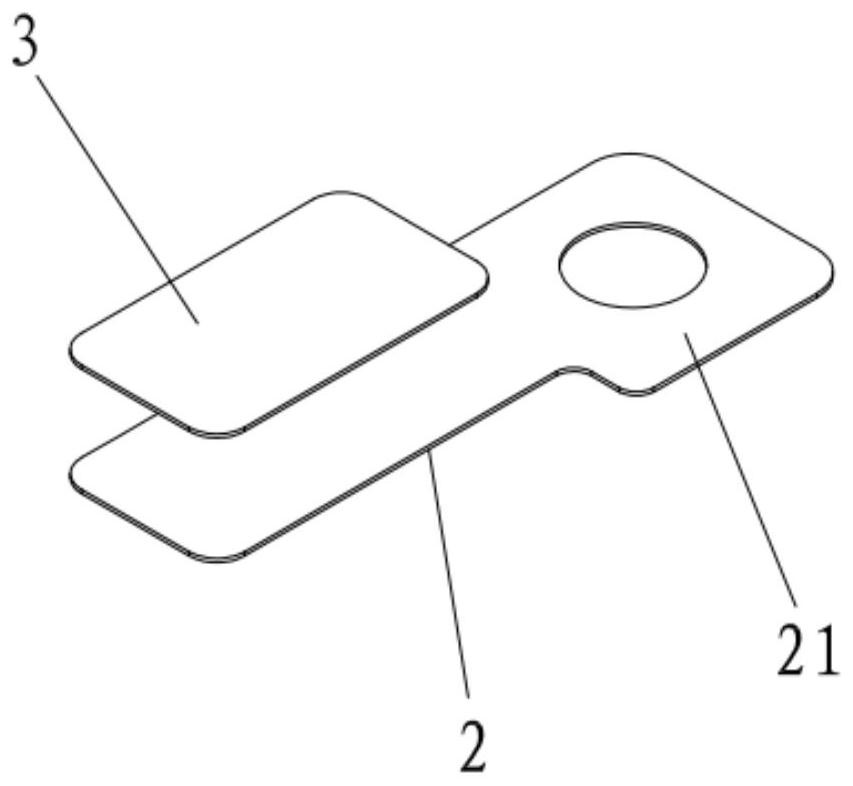

[0033] refer to Figure 1 to Figure 6 , a method of one-time waste punching and forming, the method is: half-cut the product through multiple knife paths, so that the finger 21 waste and the outer frame waste are connected together, so as to realize one-time waste discharge.

[0034] To illustrate further, the method includes:

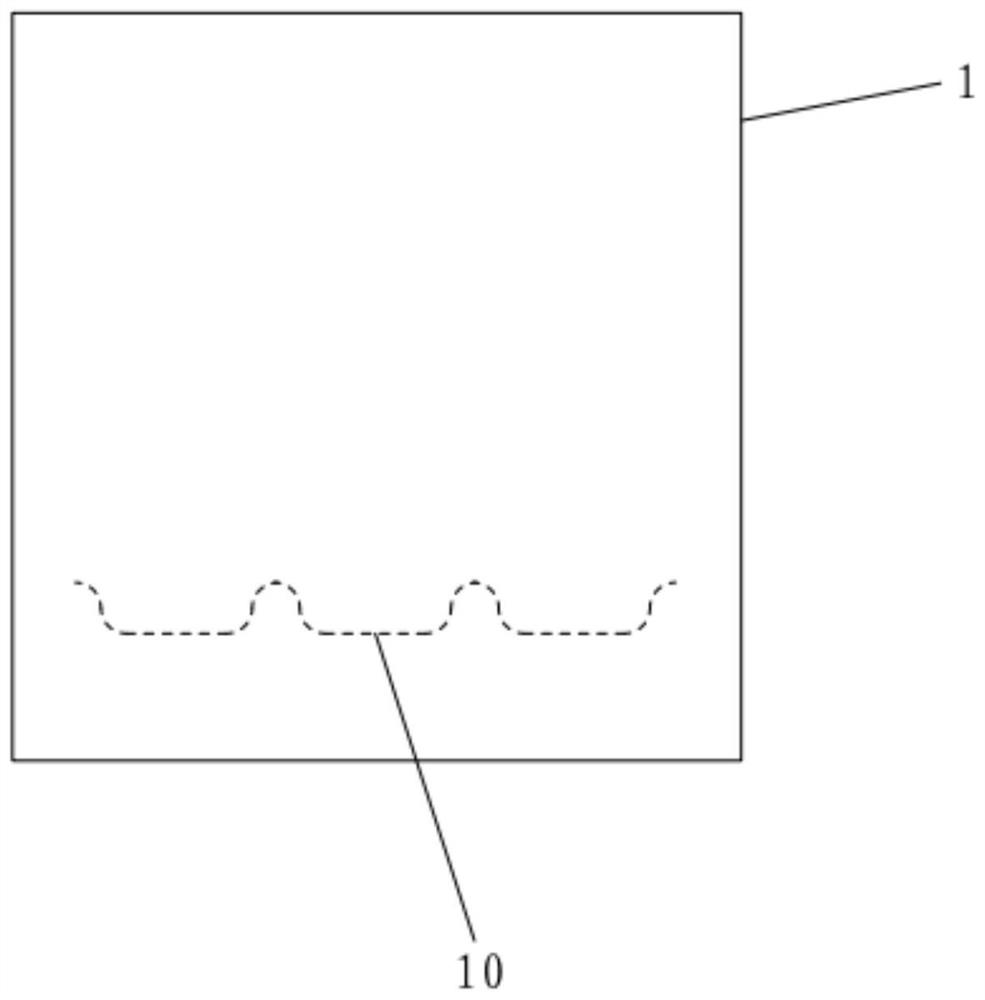

[0035] S1: the bottom edge 10 of the outer frame of the half-cut substrate 2;

[0036] S2: After the composite main material 3, half-cut the side knife 30 at the finger position 21, and half-cut the edge 20 of the outer frame;

[0037] Wherein, in step S2, the bottom edge 10 of the outer frame is not punched.

[0038] To further illustrate, in step S1 , the substrate 2 is first compounded on the support base 1 , and then the bottom edge 10 of the outer frame of the substrate 2 is punched out to reach the support base 1 in half.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com