Sampling device

A sampling device and extraction pump technology, applied in the direction of sampling device, etc., can solve problems such as time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

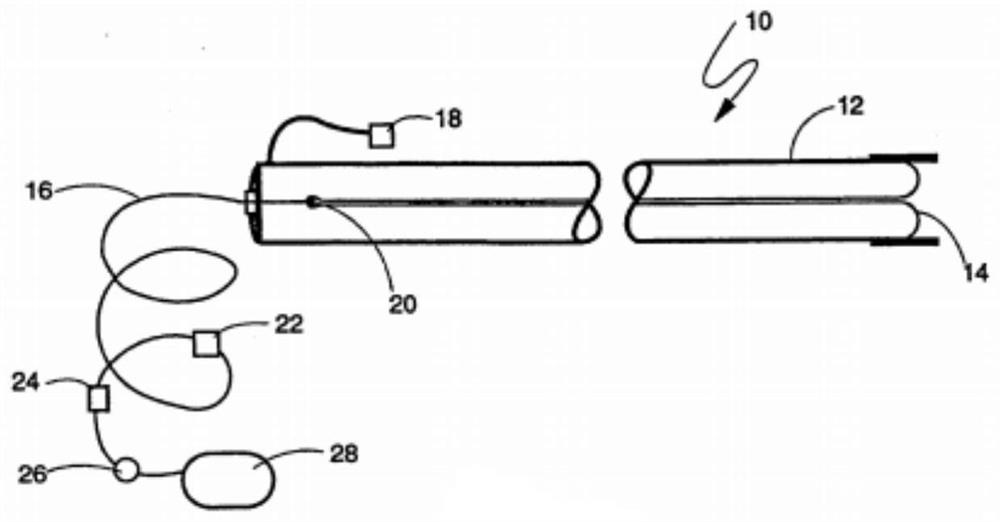

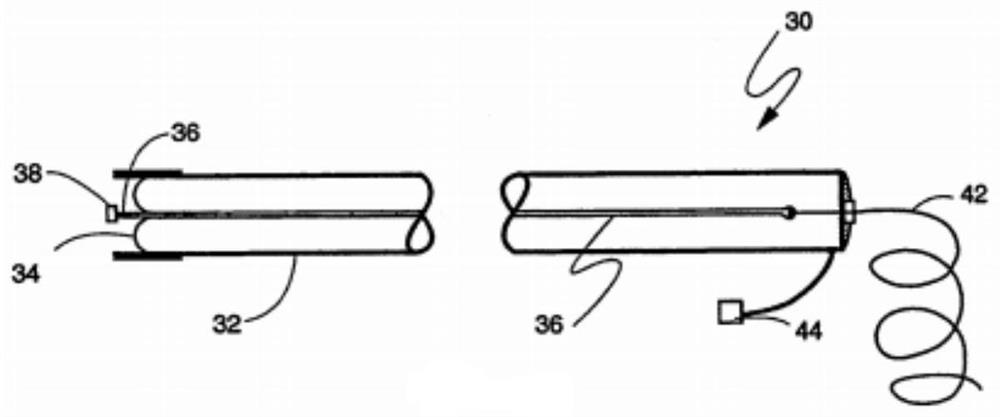

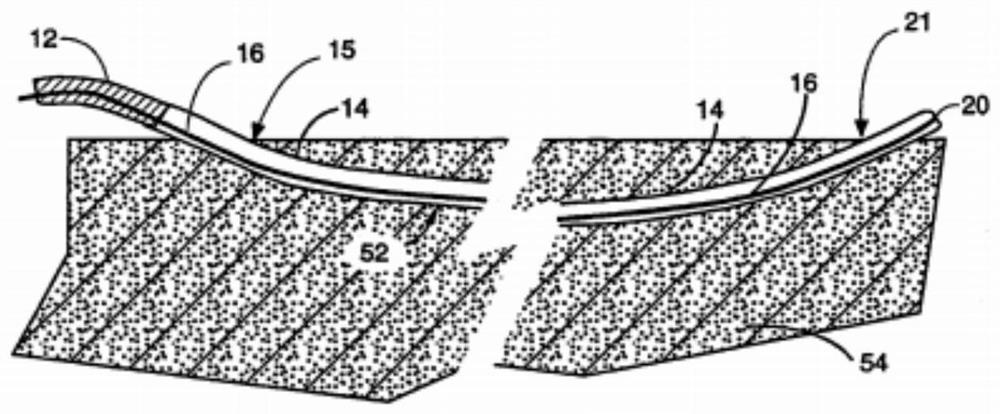

[0024] A sampling device includes a first everted diaphragm assembly and a second everted diaphragm assembly. Figure 1-2 A first everted diaphragm assembly 10 and a second everted diaphragm assembly 30 are shown for defining and forming a constant travel volume in a wellbore, tubing, or the like. As used, the term "wellbore" shall be construed to refer to a wellbore passing through a formation, pipe or similar cylindrical volume having two open and accessible ends, i.e. a generally horizontal borehole geometry shape. As explained more fully hereinafter, the diaphragm 14 is everted through the bore and is operably connected to the inverted diaphragm 34 . When the diaphragm 14 is inverted, the diaphragm 34 overturns to form a constant volume therebetween through the bore.

[0025] figure 1 More particularly shown is a first everted diaphragm assembly 10 including a first canister 12 for housing a first diaphragm 14 . A withdrawal tube 16 is connected to the first diaphragm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com