Multi-core-group capacitor strip trimming machine and working method thereof

A capacitor and rib cutting machine technology, which is applied to capacitors, capacitor manufacturing, circuits, etc., can solve the problems of poor lead length consistency of capacitors, manual separation of products and frame waste, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

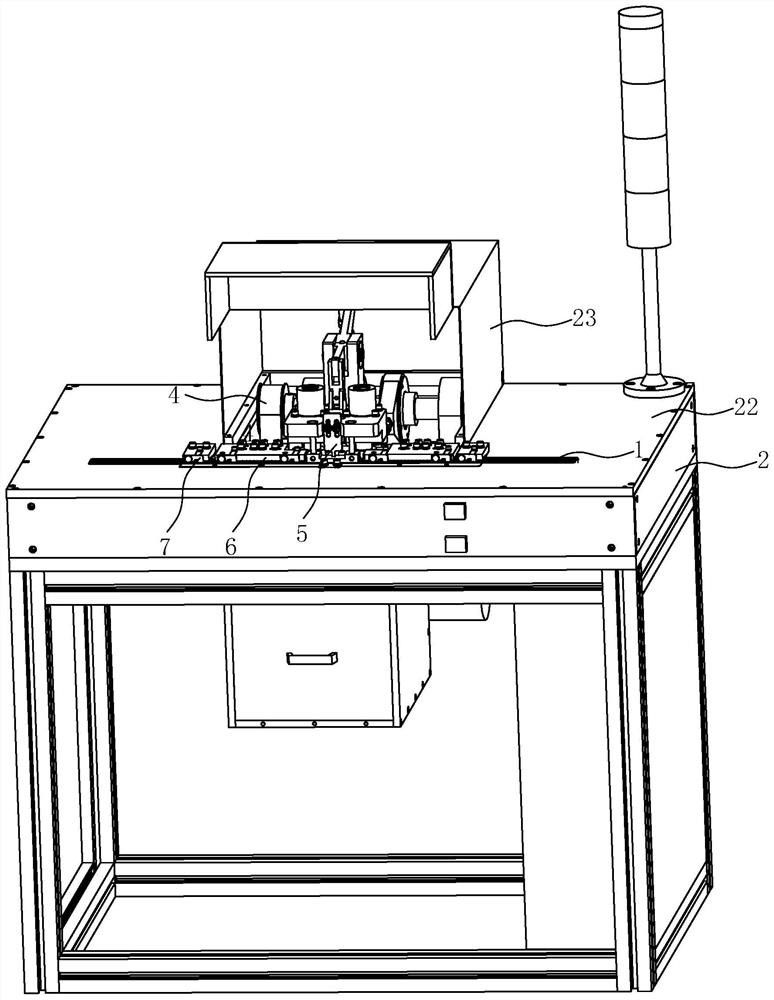

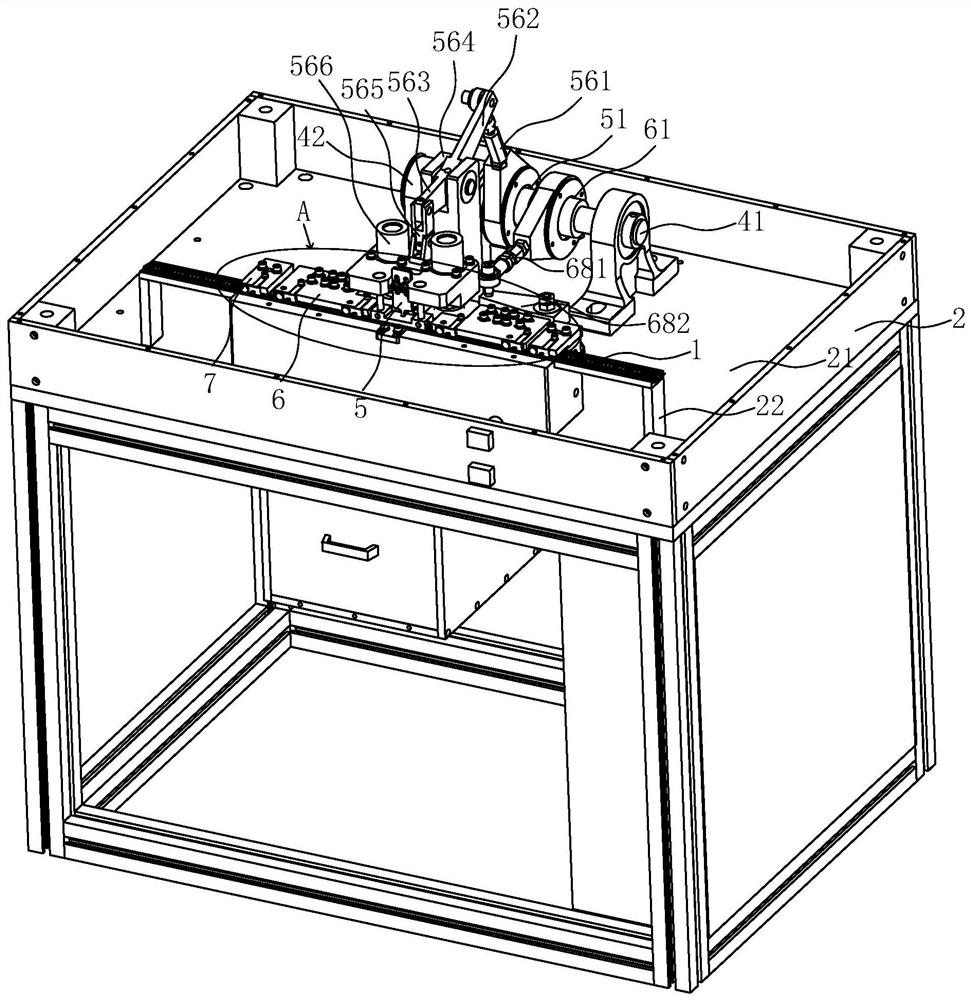

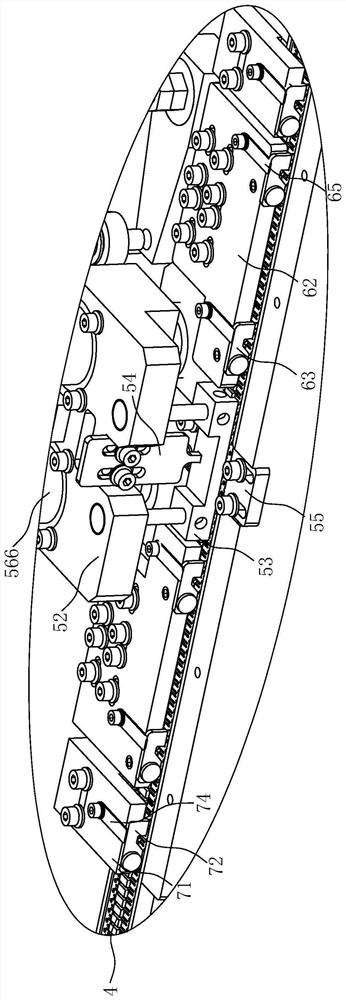

[0033] like Figures 1 to 7As shown, the multi-core capacitor bar 1 includes a frame 12 and a plurality of capacitors 11 arranged at intervals in the frame 12. A plurality of positioning holes 13 are provided on both sides of the frame 12, and the multi-core capacitor bar 1 tendon cutting machine is used for Both sides of the frame 12 are cut away to separate the capacitors 11 . The tendon cutting machine includes an operating table 2, a position-limiting track arranged laterally on the operating table 2 to place the capacitor bar 1, a rotating mechanism 4 arranged on the operating table 2, a first eccentric wheel 61 arranged at intervals on the rotating mechanism 4, and The second eccentric wheel 51, is arranged on the limit track top and is driven by the first and second eccentric wheel 51 and moves up and down a small punching mechanism 5, is arranged at intervals above the limit track and is driven by the second first eccentric wheel 61 left and right small Two moving tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com