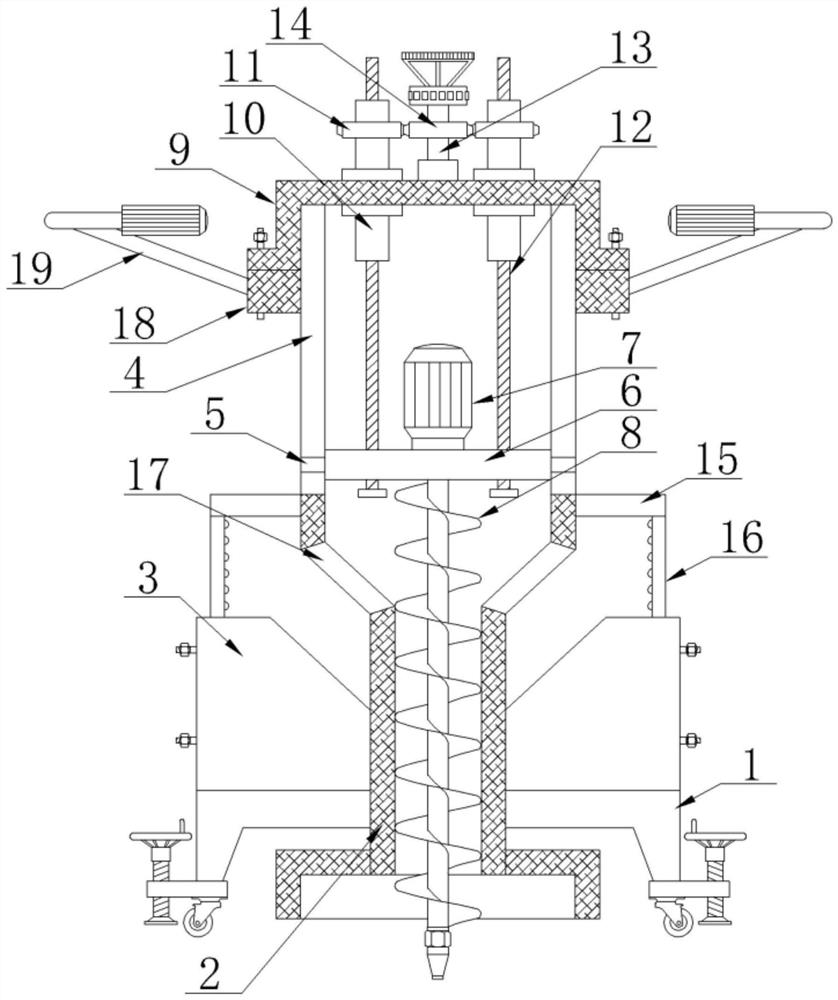

Rock-soil sampling device with gravel removal function and for geological survey

A technology of geological survey and sampling device, applied in sampling device, solid separation, sieve and other directions, can solve the problems of discarding soil samples and reducing the accuracy of soil sample detection data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] 1) Extraction of rock and soil: when borrowing soil, first lower the cylinder body 2, at this time the rock and soil outlet 17 is attached to the rock and soil collection assembly 3, manually rotate the rotating rod 13, and the rotating rod 13 rotates to make the movable cylinder 10 Rotation, the threaded rod 12 can be rotated to drive the drive mounting plate 6 to descend. Before the descending, the drive motor 7 is started, and the drive motor 7 drives the screw borrow rod 8 to rotate, lifting the rock and soil to the top, and then the rock and soil passes through the rock and soil outlet 17 Enter into the geotechnical collection assembly 3;

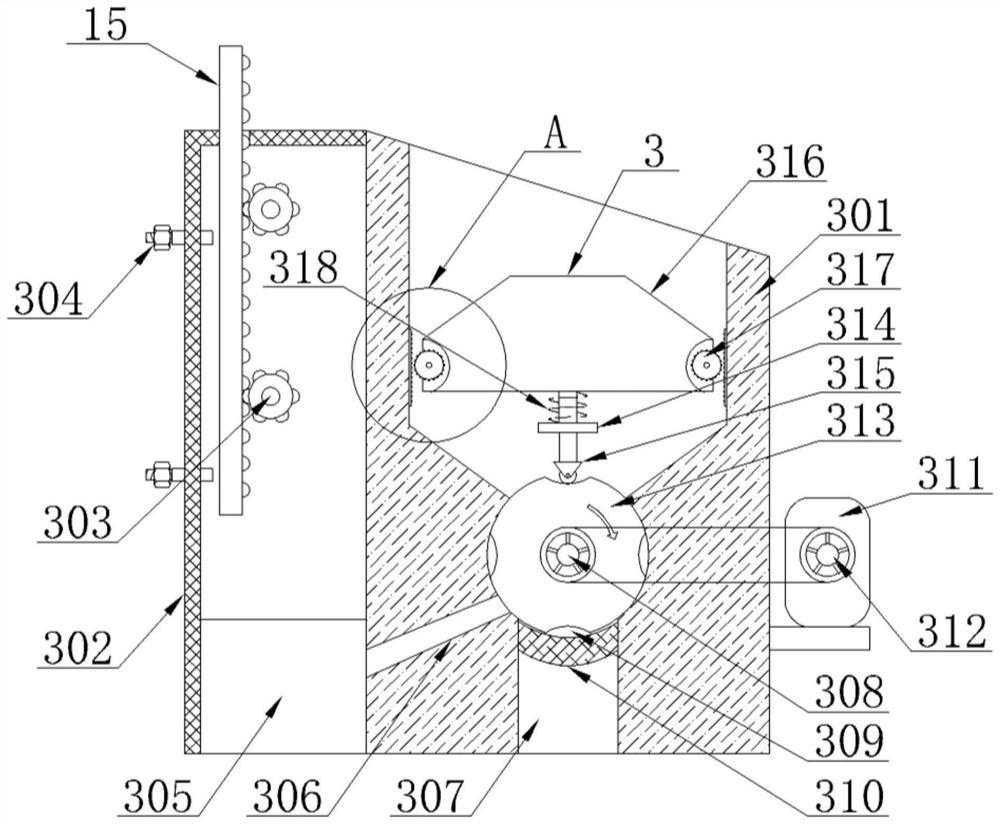

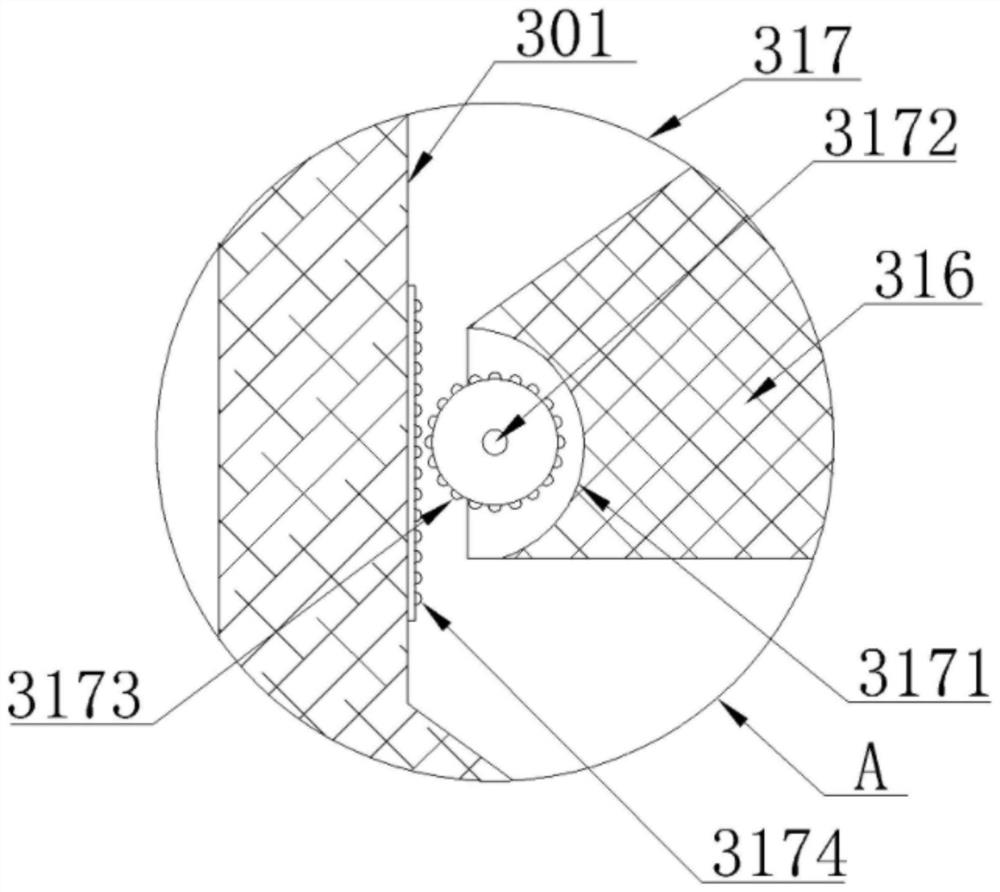

[0030] 2) Separation of rock and soil: the rock and soil entering the inner cavity of the shell 301 will be crushed by the rock and soil crushing component 317, and the crushed rock and soil and the hard soil doped in the rock and soil will be crushed and crushed. The rock and soil and hard soil blocks after screening are screen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com