Connecting structure for profiling gauge

A connection structure and inspection tool technology, which is applied in the direction of mechanical devices, measuring devices, instruments, etc., can solve the problems of inability to adapt to the connection structure of profiling inspection tools, low detection efficiency of inspection tools, and non-compliance in size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

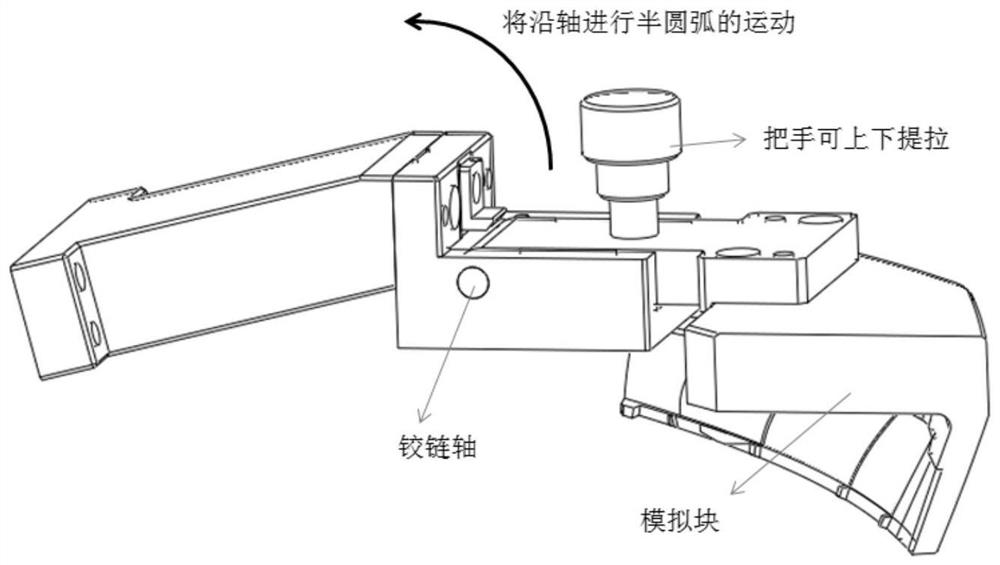

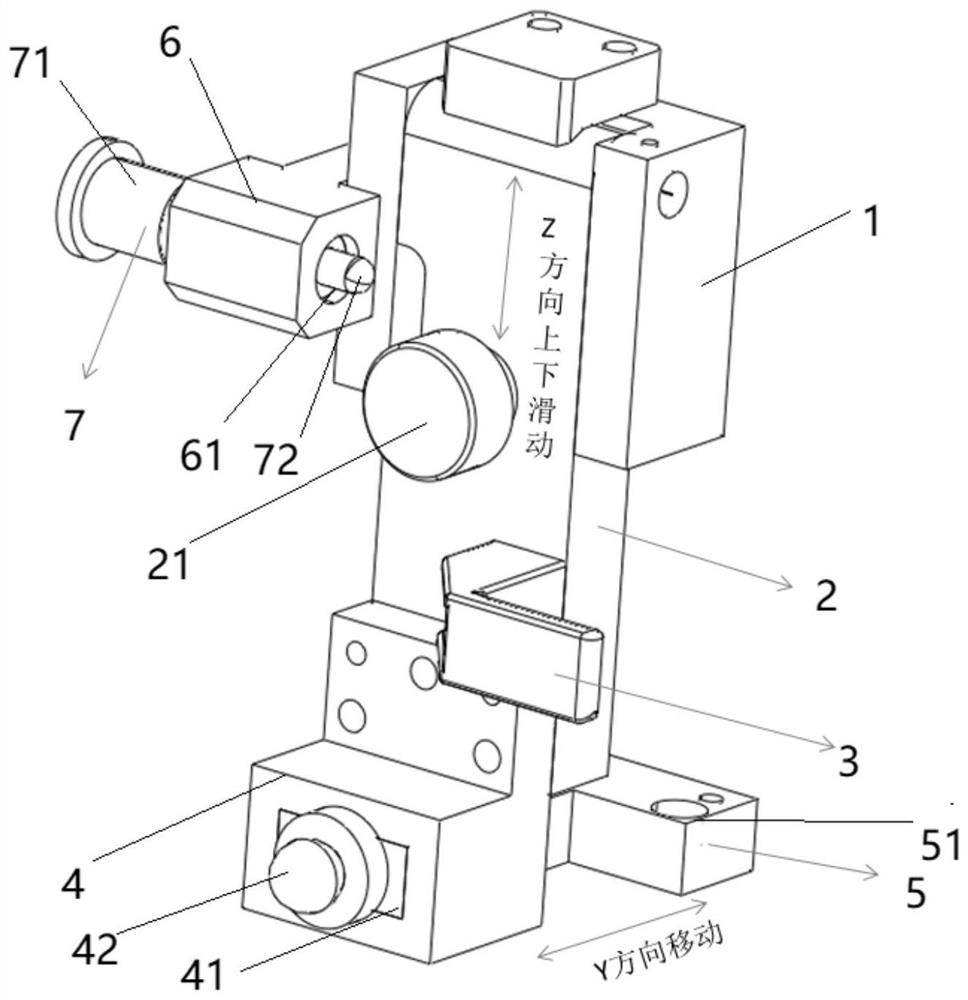

[0032] In this embodiment, the connection structure used for the profiling inspection tool includes a U-shaped plate 1, a first slider 2, a handle 3, a connecting plate 4 and a second slider 5, see figure 2 .

[0033] The first slider 2 is movably arranged in the U-shaped board 1, and can slide relatively along the length direction of the U-shaped board 1; the handle 3 is arranged on the side wall of the first slider 2, and the operator holds it with one hand when simulating assembly. Hold the handle 3 to realize the position adjustment and connection assembly of the connection structure, and adjust the Z direction of the first slider 2 by holding and adjusting the handle 3 .

[0034] A limiting block 21 is provided on the side wall of the first sliding block 2 . The U-shaped plate 1 is provided with a telescopic limiting member, which can block and limit the horizontal displacement of the limiting block 21 when the telescopic limiting member is extended. The telescopic lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com