An assembly method of an aeroengine low-pressure turbine shaft-disk assembly

A low-pressure turbine shaft, aero-engine technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve the problems of difficult alignment of macro displacement, low operating efficiency of assembly methods, affecting the centering accuracy of components, etc. Worker skill requirements and labor intensity, meeting assembly consistency requirements, and improving the effect of docking assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

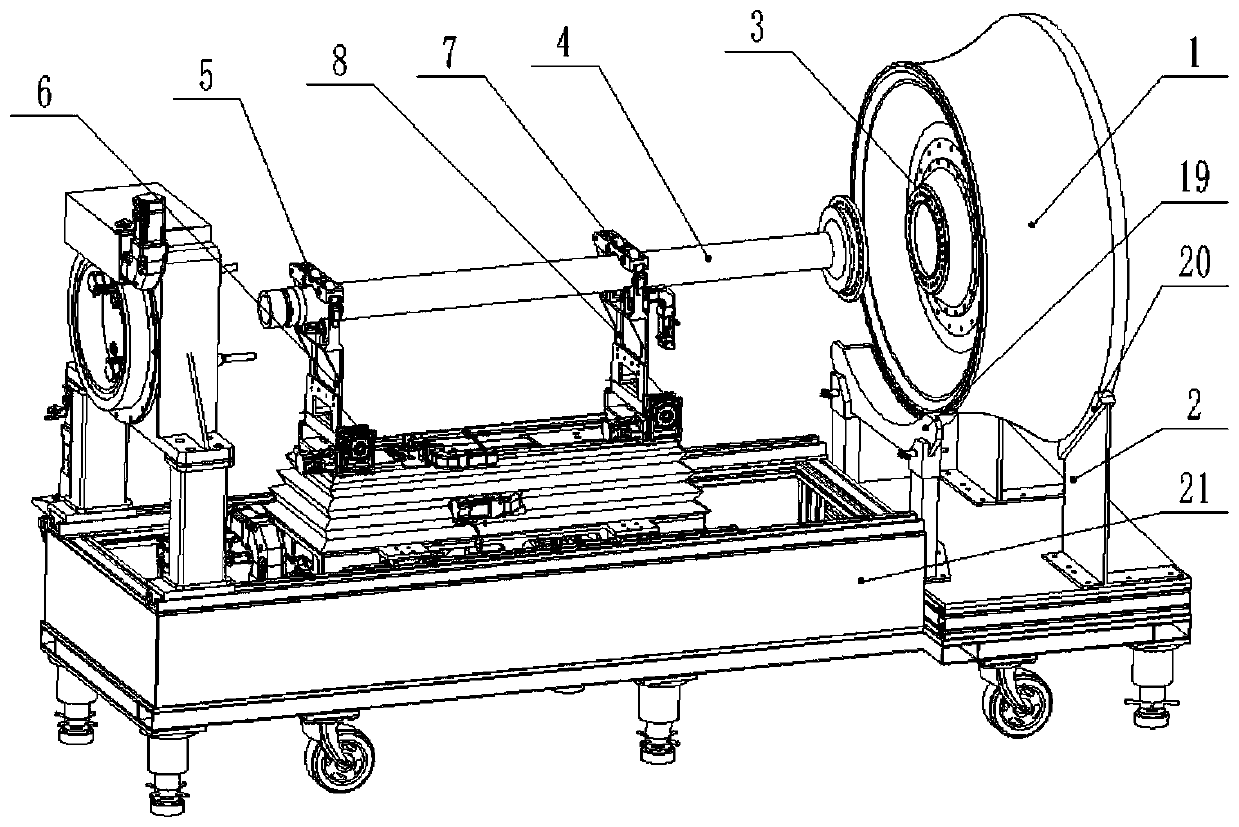

[0042] A method for assembling an aeroengine low-pressure turbine shaft-disc assembly, such as Figure 1-6 shown, including the following steps:

[0043] (1) Workpiece installation: such as figure 1 As shown, the turbine unit body 1 is fixedly installed on the turbine fixture 2, and the axis of the connection plate 3 is in the horizontal direction; the tail end of the turbine shaft 4 is installed on the turbine shaft support rod I6 in the vertical position through the claw I5, and the other end The end is installed on the turbine shaft support rod II8 in the vertical position through the claw II7, and the axis of the turbine shaft 4 is in the horizontal direction;

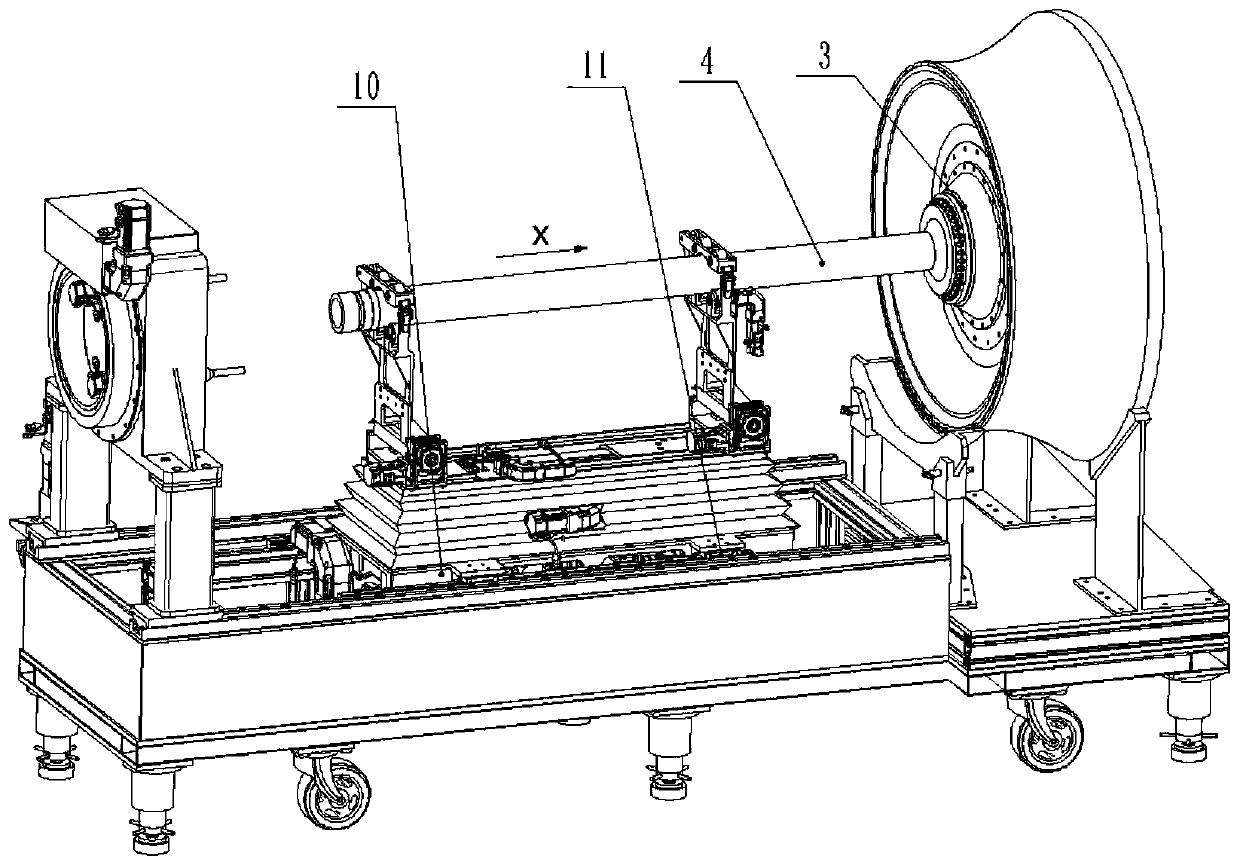

[0044] (2) Turbine shaft 4 pose adjustment: such as figure 2 As shown, by observing and measuring the end face parallelism deviation and axis center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com