Winding device of warp knitting machine and processing technology applying same

A technology of winding device and warp knitting machine, which is applied in the field of warp knitting machines, can solve problems such as cumbersome operation, and achieve the effects of convenient operation, prevention of cloth roll deviation, and reduction of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

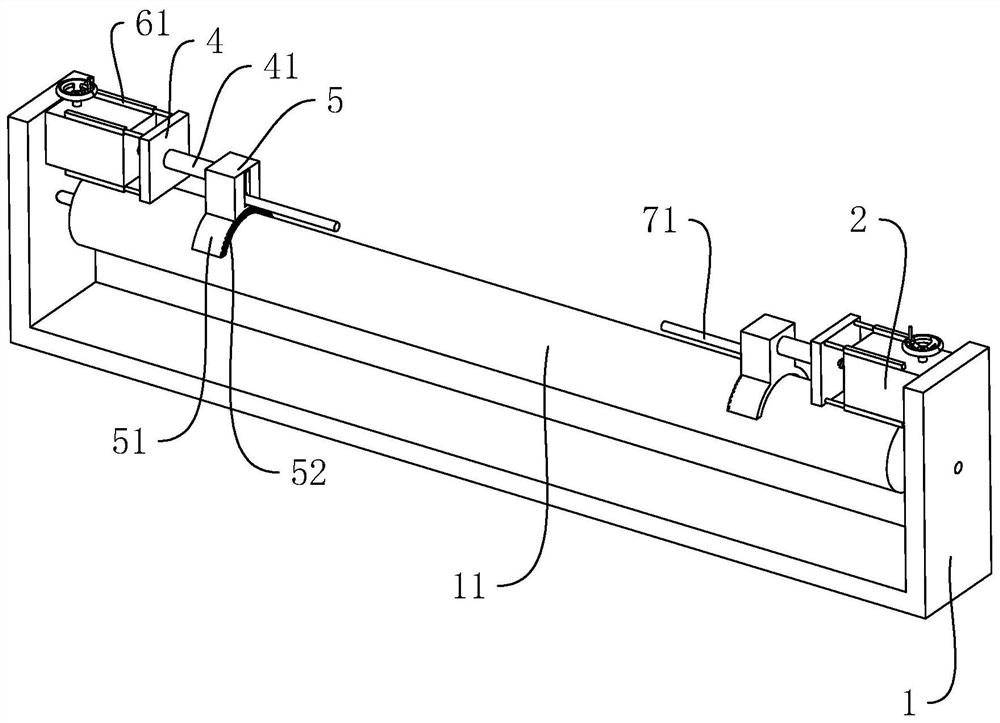

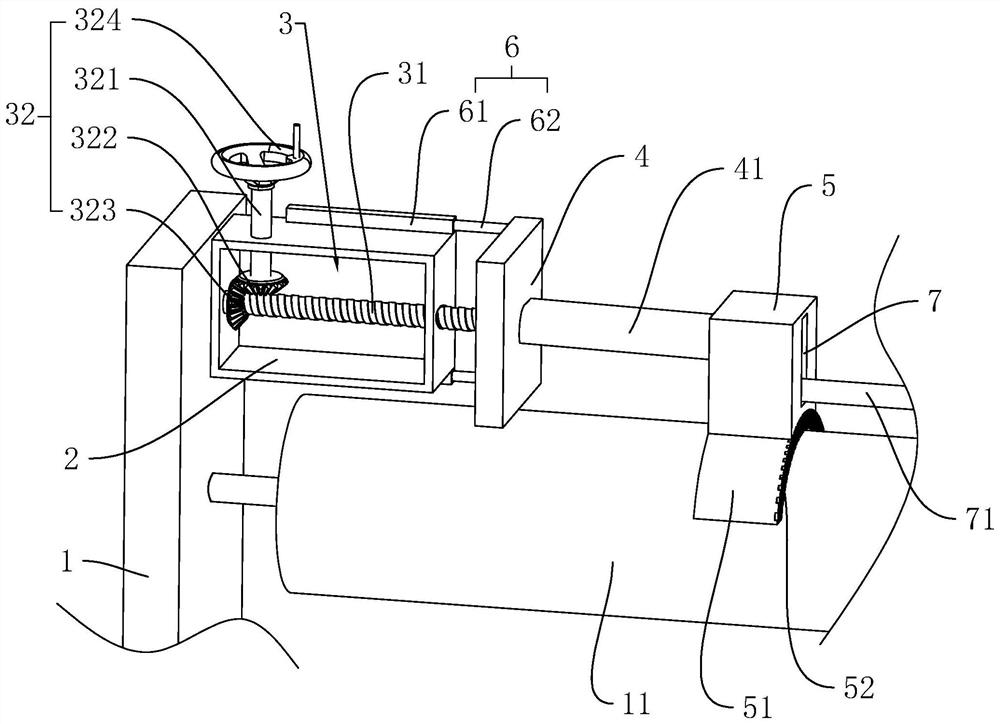

[0040] The following is attached Figure 1-4 The application is described in further detail.

[0041] The embodiment of the present application discloses a winding device for a warp knitting machine. refer to figure 1 and figure 2A winding device of a warp knitting machine comprises a vertical support 1, the support 1 is rotatably connected with a horizontal winding roller 11 through a bearing, and the winding roller 11 is rotatable by being connected with a drive motor. The opposite side walls of the bracket 1 are respectively fixed with horizontal connecting blocks 2 by bolts, and the connecting blocks 2 are arranged directly above the winding roller 11 . The connecting block 2 is arranged as a hollow cuboid. The inner cavity of the connecting block 2 is provided with a moving mechanism 3. The moving mechanism 3 extends out of the connecting block 2 and is connected with a moving block 4. The moving block 4 is vertical and square.

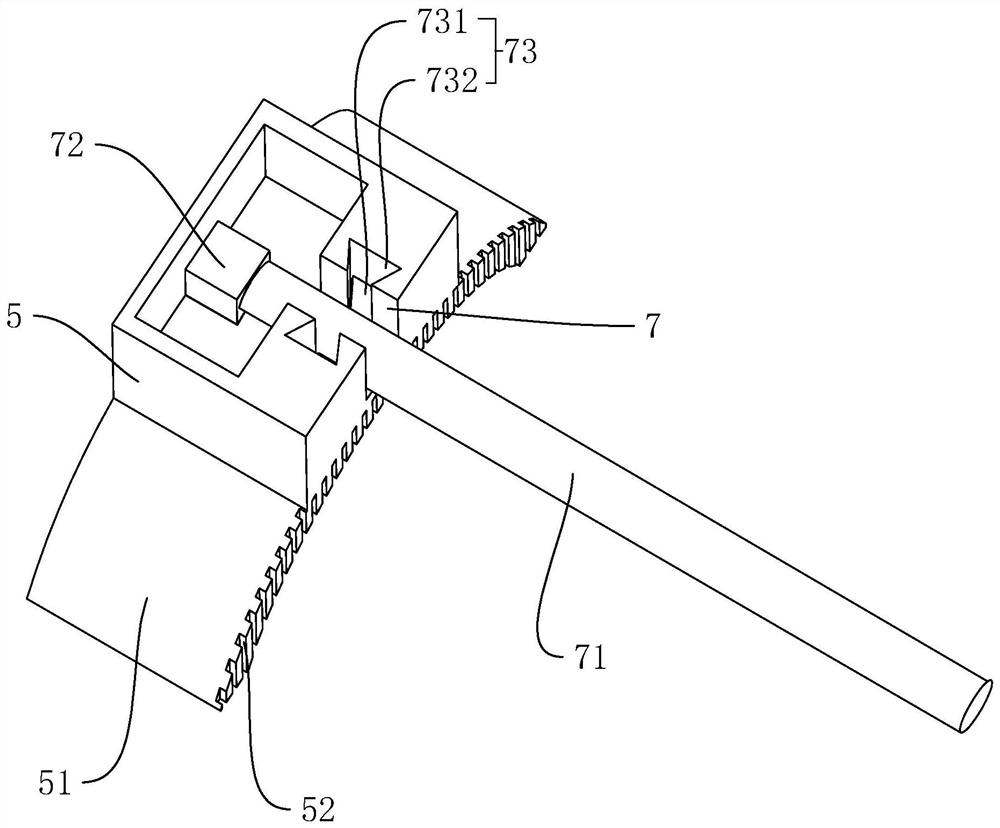

[0042] refer to figure 2 A horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com