Dry type granulator

A dry granulator and granulator technology, which is applied in the direction of die extrusion granulation, etc., can solve the problems of easy stratification, uneven density, and different powder particle sizes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

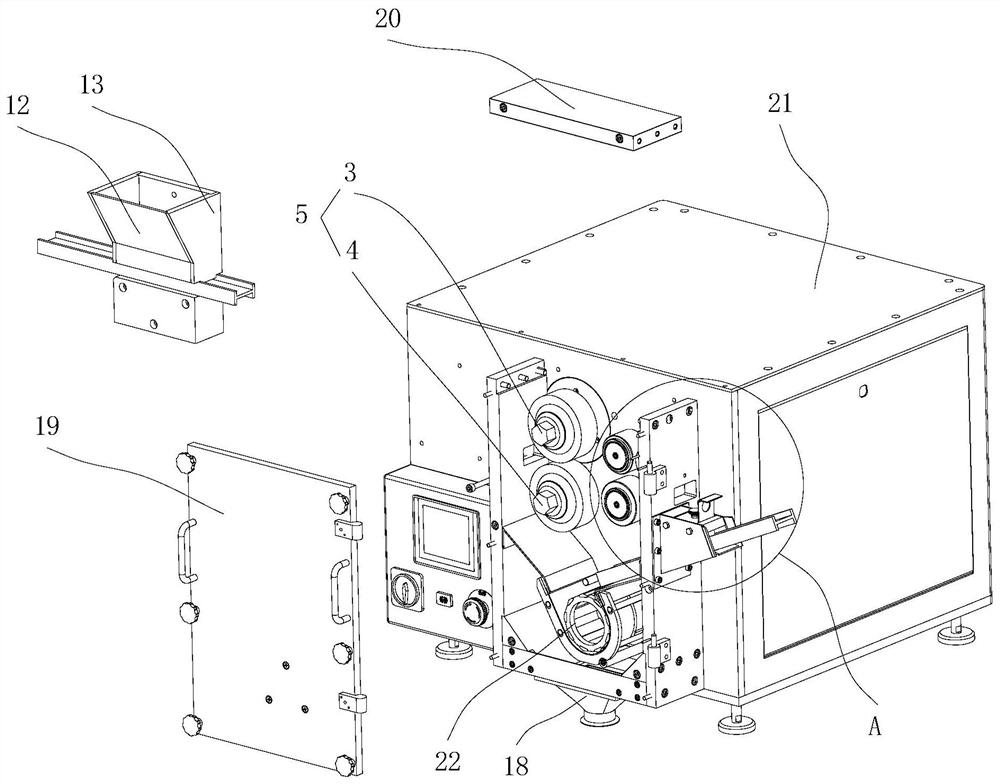

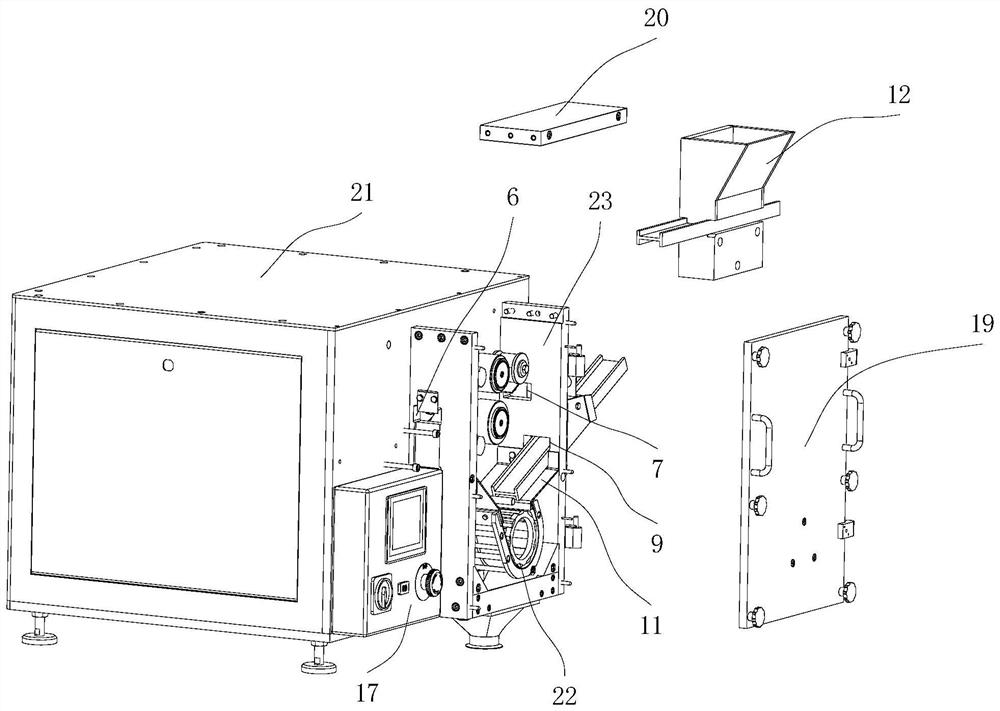

[0035] The dry granulator of this embodiment, such as Figure 1-Figure 3 As shown, it includes a rolling mechanism, a grading mechanism and a box body 1. The rolling mechanism includes a first driving member and a rolling assembly 5 connected to the first driving member. The first driving member is suitable for driving the rolling assembly 5. The grading mechanism includes a second driving member and a grading assembly connected to the second driving member, the second driving member is suitable for driving the grading assembly to move; the rolling assembly 5 and the grading assembly are arranged inside the box body 1, and the grading assembly is arranged inside the box body 1. The first driving part and the second driving part are arranged outside the box body 1; specifically, the first driving part and the second driving part are arranged in the installation box 21, so that the appearance of the whole device is beautiful and dust interference is reduced.

[0036] Such as fi...

Embodiment 2

[0051] For the dry granulator of this embodiment, on the basis of the first embodiment, the feeding mechanism described in the embodiment is further limited. Such as Figure 5 , Image 6 with Figure 7 As shown, the feeding mechanism also includes a housing structure 12. The housing structure 12 includes a flat material part and a mounting part. A feeding channel is formed between the flat material part and the material receiving part 2. A storage bin for storing materials. Preferably, the edge line of the flat material part is parallel to the material receiving plate 14, so that the material passing through the feeding channel is evenly laid on the material receiving part 2. It should be noted that the structure of the flat material part can be set according to actual needs.

[0052] Specifically, the accommodating structure 12 in this embodiment is a U-shaped structure in a top view, and the feeding structure 13 is connected to the accommodating structure 12 to block the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com